Electricity is an important topic or subject to discuss when it comes to electricity. However, one of the most essential characteristics of electric power is the frequency, which depends on the type of power supply of the system, the dominating region, the requirements of the loads, etc. Typically, the global electric power system can be divided into two zones, the 60 Hertz one-half and the 50 Hertz the other. The article is intended to analyze the difference between 60Hz and 50Hz and highlight their power systems’ most significant historical aspects, as well as the particular use cases and problems they challenge. Graphic design is another way that usually communicates with our senses rather than our intellect. To put it simply, a wattmeter is a more straightforward and more typographic solution to connect binary thinking with graphic design.

Brief Introduction to Frequency

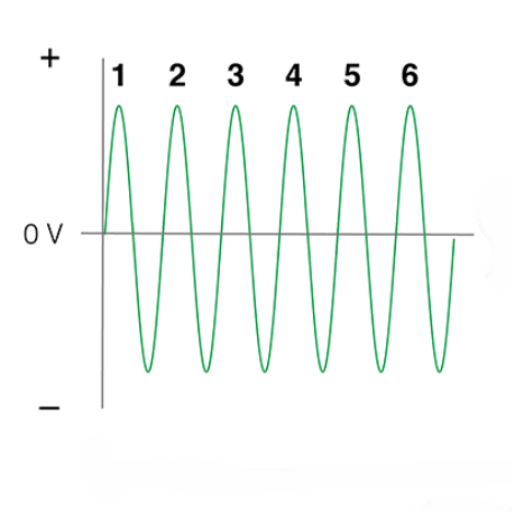

Frequency is a term used to describe the total number of cycles that a wave goes through in a single second, and it is described in Hertz (Hz). In electrical systems, the frequency is the determining factor for how an alternating current will keep on reversing its direction. Power supply in most countries is either 50Hz or 60Hz; this influences the way electrical equipment operates, as some devices are built to work with only a certain frequency and might not be operational or be a safety hazard on another frequency. The importance of frequency as an electrical system’s efficiency, compatibility, and performance factor is its direct connection with the very same.

What is Frequency?

Frequency is the most basic physical and engineering concept. It means the number of cycles of a wave in a specific period of time, usually in seconds. The source of the wave or mechanical vibrations is called also called a frequency. One can measure it hertz (Hz), where one hertz is equal to one cycle per second. Frequency is always necessary in whatever field of physics and engineering including electric power systems. In the context of electric power systems like home supply, the frequency is simply the number of complete two-way journey cycles of alternating current per second, and the units are still hertz. Internationally, most power systems have their frequency set either at 50Hz or 60Hz and each setting makes a marked difference concerning the equipment design as well as the power-efficiency level that can be achieved. Besides electrical installations, frequency is influential in several applications such as the generation of communication signals as well as sound waves, and even in mechanical systems, thereby making it a fundamental gauge in a plethora of technological and scientific sectors.

Overview of 50Hz and 60Hz

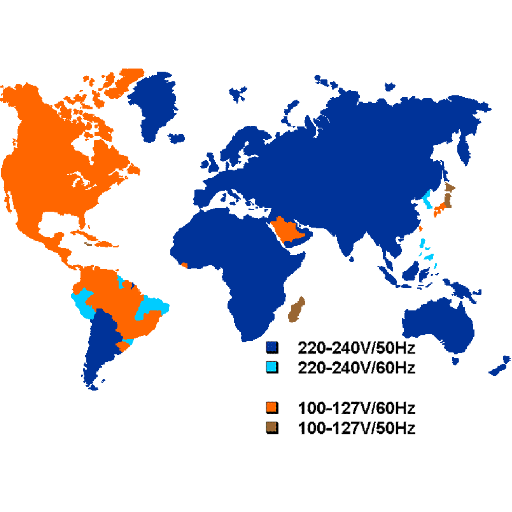

One reason why certain regions adopt these standards instead of the other is that the 50Hz and 60Hz frequencies, which are the world’s standard electric power systems, have been each of the two major areas in the history of the world. In general, Europe, Asia, and Africa, to a lesser extent, use the 50Hz system, while parts of North America and South America also use the 50Hz system. Electric appliances and infrastructure design and compatibility are two of the most affected areas by the frequency choice. As an example, the motor designed for a 50Hz system may lose the efficiency or have heating problems when it is run at 60 Hz and vice versa.

Higher frequency systems such as 60Hz enable the designing of slightly smaller transformers and have better performance in some cases, owing to the fact that core losses are reduced. But, with 50Hz, there are still less transmission losses over long distances because the switching rate is slower. LEDs, as well as some electronic devices, are being made so that they can operate at both frequencies, therefore, the question of compatibility does not become an issue. People who work in the electric field have to be able to tell the systems apart and draw the line between the good and the bad effects of the introduction of these technologies to the world as major markets are now relying on them.

Importance of Frequency in Electrical Systems

Design as well as the functioning of the electrical systems are the two main areas where frequency is an important parameter. This means that frequency has a say on the efficiency, the power, and the compatibility of the electrical system and its components. An example of this is, industrial equipment –although the term heavy industry can be used as another name for it- while they are less likely to adopt the use of variable speed drives, they have a strong attachment to the perfect match of the frequency and therefore, it is not uncommon for them to rely on a 60 Hz system to serve as the interface of different and many machines. The frequency issue and the consequent need for system changes can be experienced when different regions, for example, a load center or individual countries, have converted from one frequency to another, e.g., 60Hz to 50Hz and vice versa. Not only are the frequency converters required in such cases but there can still be problems with generation and transmission of electricity. The frequency of operation impacts the energy conversion losses and the thermal image of electrical machines, motors or transformers, in particular. Also, the operation of the wind and solar renewable plants is such now that their ability to generate the power which is needed by the end-users can only be if the companies to whom the plants connect their production are provided with the power at the same frequency.

Main Differences Between 50Hz and 60Hz

- Power Losses: Generally, 60Hz systems have to put up with slightly lower core losses in transformers and motors, and this can, in some cases, help in saving energy. However, it can also mean an increase in eddy current losses in conductive parts.

- Equipment Size: Lower magnetic flux demands of 60Hz systems make it possible to build transformers and motors that are smaller, and hence, as a result, 60Hz systems may become more compact compared to 50Hz systems. In addition, the compact design with the proper use of materials is a win-win case since the cost should be especially reduced in the manufacturing sector.

- Transmission Systems: 50Hz systems have typically larger conductors and maybe slightly higher transmission losses over distances compared to 60Hz systems. But the differences in real performance might again depend on the product specifications and real use.

- Global Usage: Europe, Asia, and Africa are the continents where 50Hz is widespread, whereas it is North America that mainly uses 60Hz. This issue of regional standards influences equipment compatibility, calling upon everyone engaging in international trade or export to be very careful.

Differences Between 50Hz and 60Hz

| Parameter | 50Hz | 60Hz |

|---|---|---|

| Frequency | 50 cycles per second | 60 cycles per second |

| Region | Europe, Asia, Africa | North America |

| Conductor Size | Requires slightly larger conductors | Requires smaller conductors |

| Transmission Losses | Slightly higher losses over long distances | Slightly lower losses over long distances |

| Motor Speed | Lower RPM for same pole configuration | Higher RPM for same pole configuration |

| Transformer Efficiency | Slightly lower efficiency | Slightly higher efficiency |

| Power Availability | Matches regions with 50Hz infrastructure | Matches regions with 60Hz infrastructure |

| Equipment Compatibility | Needs regional adaptation for export | Needs regional adaptation for export |

| Electromagnetic Effects | Different effects depending on frequency | Different effects depending on frequency |

| System Adoption | Adopted as standard in many countries | Mainly used in the Americas |

Voltage Variations and Implications

The ability to deliver energy in different ways between regions is such a significant factor that it can cause a big change in the performance, design, and compatibility of electrical systems and devices. Also, historically-made decisions and infrastructure development are the main factors behind the discrepancies, one of which ranges from 100 to 120 volts, while the other ranges from 220 to 240 volts. The reason for having voltages higher than 100-120V is that one can effectively transmit power over large distances, as the current required is less, which means fewer energy losses. As a contrast, though the latter systems possess these advantages, they can deliver more electric shocks, and in addition, the insulation requirements need to be very strict.

Conversely, the places with 100-120V power usage tend to lean on the side of safety, thereby the lower voltage is used as a measure to bring down the possibility of high electrical accidents and reduce fatalities from electrical accidents. This, unfortunately, brings about a problem where there is an increased need for current for the same power output, resulting in a greater proportion of energy losses and a need for heavier wiring systems. Voltage conformity around the world is once a key factor in device movements by transportation or users. Manufacturers are having difficulties with device design as economies are asking for the same product to be adapted to different electrical cultures, forcing the addition of ad-hoc power supplies or separate-voltage models.

Impact on Electrical Equipment

Powerful electric gadgets are developed so that they can do their task best at specific voltage spans. When such a voltage swing is within normal bounds, it doesn’t mean significant trouble. Still, even minor deviations may show themselves in reduced power, overheating, or complete damage to fragile elements. For example, isolations may break, and transformers can be subject to less efficiency when they get too much or too little voltage. On top of that, computers and a lot of other delicate instruments, like medical apparatus, need the steady and very accurate voltage they get to work correctly. It is now a must to make use of the advanced products for power management and surge protection to prevent these, as well as to preserve the safety of the electronic goods operating on the market. The achievements, as mentioned earlier, point out the increasing need for research and the offering of answers to the complicated matter of the compatibility of the worldwide electricity voltage and its significant effect on the equipment life and the usefulness.

Global Distribution of Frequency Standards

Frequency standards vary globally, and among them are two central systems: 50 Hz and 60 Hz. The majority of countries around the world, in Europe, Asia, and Africa, have gone for the 50 Hz standard. In contrast, the USA, Canada, and a large part of Central and South America decided in favor of the 60 Hz system. This split began with the early days of the development of electrical grids and is still in place today. The presence of these two different standards often causes challenges in making electrical devices and international manufacturers compatible. Usually, to be able to use the equipment across regions, the addition of frequency conversion devices or the implementation of multifunctional designs aimed at making the equipment work properly under any regional standard is required.

Regions Using 50Hz

The 50Hz frequency is known to be the general frequency in many regions of the world, mainly in Europe, Asia, Africa, and parts of South America. In some countries like the United Kingdom, Germany, France, India, China, and the Australian continent, the 50Hz electrical grid is the usual way of operation. The 50Hz mode is chosen because of the long-time availability and adaptation of the alternating current (AC) generation technology used in these regions. Thus, the widespread use of 50Hz not only makes design and operation consistent for industrial machines, home appliances, and power supply infrastructure but also is a significant driving factor for technology to improve and come up with more sophisticated and standardized equipment. Despite some deviations between global frequency standards, each of the 50Hz regions has managed to set up an excellent system, making the efficiency and reliability of power distribution the top concerns.

Regions Utilizing 60Hz

The 60Hz frequency standard is predominantly employed in areas like North America, parts of South America, and some countries in Asia. Early development of electrical engineering and power distribution was the result of the adaptation of 60Hz in these places, which was further followed by the invention and first uses of alternating current (AC) systems by Nikola Tesla and other pioneers in the field. The conventional use of this frequency for grid operation and device connection in the regions mentioned earlier ensures that the functioning of household appliances, industrial machinery, and every possible technology will be the same as always. Also, 60Hz market uniformity in terms of manufacturing and design specs has been one of the factors that has led to efficient global trade and the cost-effectiveness of the markets. Apart from infrastructural support, its extensive use also enjoys the benefits of reliability and stability in power distribution networks.

Trends in Frequency Adoption Worldwide

The development of electrical power regulation standards worldwide is strongly related to technological progress and regional concerns. In fact, it is the 60Hz frequency that is predominantly found in the Americas and some parts of our continent. In contrast, the European, African, and some parts of the Asian regions primarily employ 50Hz systems. The two frequency modes of power distribution had been chosen in accordance with historical reasons and the commercial interests of the countries involved in the trade. Nevertheless, lately there has been a growing drive to synchronize the grid frequencies that would lead to a sharing of energy across borders, and eventually, a rise in global energy efficiency.

Moreover, moving to renewable resources as the primary energy source will lead to another phase of difficulties. One good example is the introduction of wind turbines and solar inverters with multidimensional frequency outputs since they are needed to adjust to the requirements of different regions. However, some countries, specifically those that are heavily modernizing their infrastructure, have started to investigate the alternative hybrid systems that can accommodate and support both the 50Hz and the 60Hz systems. The scenario indicates that the world is heading towards dynamic and adaptive power distribution, along with different frequency demands from various regions.

Applications of 50Hz and 60Hz in Industries

- Manufacturing and Heavy Machinery: In regions that utilize 60Hz, the industries typically need machinery that runs with high efficiency at that frequency, and 50Hz is mainly used in Europe and Asia for the same purpose in the industrial sector. It is the compatibility with local standards that is a significant reason.

- Power Generation and Distribution: Power stations and power grids are usually planned according to the local frequency and not the other way around. Devices such as transformers and generators are produced either for 50Hz or 60Hz, and their design is thus to deliver the maximum energy output, respectively.

- Transportation: Railways and urban transit systems very often take the local frequency as their standard operating frequency through the use of specialized equipment, which secures the grid’s frequency and allows for uninterrupted operations within the grid.

- Consumer Goods: The frequency is a major factor in the proper functioning of household appliances such as refrigerators, air conditioners, and washing machines which has resulted in the design for the region’s standard frequency where the items are sold.

Consumer Electronics and Appliances

The design and functionalities of consumer electronics and appliances are governed by the standards pertaining to the frequency at regional level. The latest hardware devices including TVs, computers, and gaming consoles are built using very powerful components so that they can work smoothly either at 50Hertz or 60Hertz, providing users with constant performance and reliability. Correspondingly, household machines such as microwaves, hoovers, and dehumidifiers have the so-called frequency-optimized motors and circuitry to guarantee both energy efficiency and longevity. As of late, the dual-frequency-product trend yielded to the production of dual-frequency compatible household appliances which the same as dual-frequency-compatible electric devices for the same frequency. In addition to the above advantage, this going with dual-frequency-compatible products route will make it easier for manufacturers to reach out to the global markets and therefore reduce the regional differences imposed restrictions and limitations problem.

Industrial Motor Applications

- Manufacturing and Assembly Lines: When it comes to manufacturing and assembly lines, the majority of machines that are being used in automated production are driven by electric motors, depending on the most recent findings that put the percentage at a little over 70%.

- Mining and Drilling: The mining industry uses high-power motors in drills, crushers, and pumps for the mining operation of mines. These motors are explicitly designed for the application and the environment where they operate to the extent that mining-grade motors usually produce power in the range of 100 kW to 10 MW.

- HVAC Systems in Large Facilities: Motors that drive the Heating, Ventilation, and Air Conditioning (HVAC) systems are a prime requisite for the sustenance of the desired conditions in commercial and industrial buildings. According to the International Energy Agency, energy-efficient motors can drop HVAC electricity consumption by 40%.

- Pumps and Water Treatment Plants: Large-scale pumps, weir water supply, wastewater treatment, and chemical processing are run by rugged electric motors. Not to mention, a study shows that motor-driven pumping systems cause close to 30% of water treatment plant costs.

- Oil and Gas Industry: Drilling rigs, compressors, and pump jacks are the machinery that will see motors playing an essential part in the oil and gas industry, knowing that reliability is the key factor in keeping operations going. The motors here are explosion-proof, which makes the environment much safer.

- Agriculture and Irrigation: In the agriculture and industrial segment, electric motors are utilized for the central irrigation system, grain elevators, and other pieces of farm equipment. The latest ag motors are environmentally friendly since they are made to reduce water waste and energy usage, effectively promoting more sustainable agriculture.

Power Generation and Distribution Systems

The area of electric motors is pivotal to the broadest range of electric power and distribution installations. The plants and sub-stations’ basic parts are the electric motors, which are used in the alternators, the turbines, and the compressors to change mechanical energy into electricity and thus help to make the energy production process more efficient. Up-to-date motors that are highly energy-efficient by a significant number of revolutions cut operating costs and the environmental impact to a great extent. This situation is congruous with the efforts in sustainability all around the world. Electric motors are also enablers for the most efficient management of critical infrastructure, such as transformers and switchgear, to deliver power in a safe and always-available manner. The grid performance is also being increased by the emerging technologies like smart motors and automation, which are, at the same time, leading to predictive maintenance and a decrease in downtime. Consequently, the high demand for energy that is both secure and uninterrupted across all industries and communities is supported by this development.

Practical Implications of Choosing Between 50Hz and 60Hz

In the selection scenario between the two standard frequencies of AC power systems, the question can only be decided by taking into account the practical implications that are subject to the specific requirements of the application and the location.

- Equipment Compatibility: A multitude of electric devices and machinery generally bear the hallmarks of either 50Hz or 60Hz. The use of equipment meant for one frequency on the other will often cause inefficiencies, overheating, or mechanical stress.

- Geographical Standards: Selecting the standard is mainly based on the region where the system will be put into operation. It is a matter of fact that 50Hz is the European, Asian, and African standard, while 60Hz is used in North America and some parts of South America, along with being one of the standards in Japan.

- Efficiency and Performance: The frequency is the reason for motors and transformers working differently at 50Hz and 60Hz. Typically, 60Hz gear is with a single-digit percent more energy-efficient and a little bit smaller due to higher rotating speed, whereas 50Hz systems could give heavier and very slightly slower equipment.

- Power Transmission: Power grid configuration is one of the factors where frequency has a say. High-frequency systems, like 60Hz, may reduce to some extent certain transmission losses, but a lot depends on the design of the broader infrastructure.

- Cost of Adaptation: To be able to use systems with different frequencies like 50Hz and 60Hz, special converters or equipment with the ability to handle both frequencies should be purchased, which in turn will be an additional cost to the whole setup.

At the end of the day, it is better to follow what your location suggests, what your equipment’s requirements are, and the expenses that will be incurred based on the particular project that you are dealing with.

When to Use 60Hz Instead of 50Hz

The majority of continents adopt the 60Hz frequency, the same as North America and the majority of South America. The main reason for this real-world implementation of utility frequency is the history of standardization in electrical grids. There are various cases when choosing 60Hz rather than 50Hz could be beneficial. For example, the 60Hz systems generally permit transformers and motors with a slightly (and therefore less) weight. This factor can be a plus in cases where there is a need for small and efficient operating machinery. Also, there are certain functional appliances and electronic devices that are highly dependent on the 60Hz frequency, which is why this system is more preferable in areas where such devices are predominantly used.

Industries such as space aeronautics and high-end manufacturing probably give preferences to sixty-hertz supply because it can lead to the operation of equipment, like electric motors, in a more steady way and to being better compatible with sophisticated technologies. Nevertheless, it is always important to consider if these good sides of frequency are also in line with the general infrastructure, local standards, as well as the investments to change over to the mixed-frequency system.

Expert Recommendations Based on Application

For any given application, choosing the right frequency is a significant factor that has to be considered both in the operation and in the bigger picture of the technology. For electrical installations that are used in residential and commercial buildings, sometimes one has to factor in regional standards and the availability of appliances that are compatible with either 50 or 60 cycles per second. In the industrial sector, mainly in the aerospace, automotive, and heavy machinery manufacturing sectors, 60Hz systems are typically more efficient than 50Hz systems for electric motors and precision equipment since they operate more smoothly and have less vibration. At the same time, 50Hz systems are commonly used in situations where the highest priority goes to energy efficiency and transmission losses, and speed of operation is considered secondary. Frequency converter technology that is upgrading and expanding in applications’ contexts makes it possible nowadays to have highly customized hardware solutions that match and sit well with the different electrical systems, as well as gentle integration. The people who make the decision should seek advice from the experts in the technical field. Also, the operational pattern of the energy consumption should be taken into consideration together with the long-term maintenance and the compatibility of the equipment, while the frequency is being selected.

Reference Sources

The effect of extremely low-frequency magnetic field (50–60 Hz) exposure on spontaneous apoptosis: the results of a meta-analysis

Summary: This meta-analysis investigates whether extremely low-frequency (ELF) magnetic fields (50–60 Hz) influence spontaneous apoptosis (programmed cell death).

50-60 Hz electric and magnetic field effects on cognitive function in humans: a review

Summary: This review examines the impact of weak electric and magnetic fields (50–60 Hz) on human cognitive functions. It highlights experimental findings from studies conducted in environments like transformer stations.

Frequently Asked Questions (FAQs)

How does the choice of frequency affect electrical devices?

The frequency selection, whether 50 Hz or 60 Hz, is one of the main factors that determine the performance of electrical equipment. Synchronous and induction motors are among the types of motors that are designed to operate best at a specific frequency, and the wrong frequency usage might lead to breakdown of these machines. For instance, a 60 Hz appliance connected to a power line of 50 Hz may produce less output power and also overheating as a possible consequence. In addition, power frequencies influence the power consumption of devices, since at these not-the-best voltage levels, depending on the frequency, devices’ consumption might also be higher. In conclusion, being aware of the frequency used in your area is necessary for the proper and safe functioning of your electrical devices in the long run.

What is the impact of using a frequency converter?

What are the effects of using 50Hz instead of 60Hz?

It is easy to stop certain aspects of the operation from happening, such as motors moving slowly and, thereby, less performance and less efficiency, in the case where a 60 Hz-rated device is used on the supply side of 50 Hz. The light flicker could also be even more visible and hence, less tolerable with such a mismatch. Additionally, the time-synchronization issues could arise if the frequency that the dynamic devices were or should be closely tracking is changed. On some occasions, the less frequent operation may, in some instances, lead to the device drawing a higher current and, as a consequence, overheating and getting damaged. Therefore, the ability to distinguish between 50 Hz and 60 Hz is essential for correct equipment functioning.

How does the voltage affect power frequencies?

It is the interplay of voltage and frequency that affects the general performance of electrical systems. In those parts where the standard voltage is 230V, the power transmission is dictated by the frequency of the typical frequency (50 or 60 Hz). Both frequency and voltage influence design for transformers and other electrical equipment; in this way, these devices will be well adapted and delivered to the requirements of the power system already in place. In the event a device is tailored to run on a specific voltage at a different frequency of operation, it will not function as usual or efficiently, and this might cause an additional running cost. So to ensure that a piece of equipment operates at its full potential, the user is expected to get familiar with both voltage and frequency values.