Electric motors are the brains behind the systems or machinery that control everything from industrial equipment to household appliances. Of course, motor parts repair comes in handy in the event of repair, as it’s always subject to wear and tear. Whether you are an experienced technician or a DIY enthusiast, having a basic understanding of the components of electric motors and knowing how to source the correct replacement part will help ensure the smooth operation of your equipment. The guide provides a thorough overview of motor replacement parts, including how to use them and pro tips to ensure a successful repair. Soon, you’re going to save time and money while learning the process of motor repair that will help extend the life of your electric motors!

Understanding Electric Motors

Electric motors convert electrical energy into mechanical energy, which helps operate tools, appliances, and machinery in various ways. They operate based on the interaction between a magnetic field and electric current inside the motor. There are multiple types of electric motors, with the two main ones being AC (Alternating Current) motors and DC (Direct Current) motors, which operate differently and are well-suited for different applications. AC motors are commonly used in household appliances and industrial plants to carry out specific workloads due to their economy and versatility. DC motors, on the other hand, are suitable for applications that require smooth operation, such as in vehicles and most electronic devices. This knowledge is essential whenever one is identifying the cause of or replacing any components in a system.

Types of Electric Motors

| Type of Motor | Power Source | Key Features | Common Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| AC Motor | Alternating Current | Efficient, reliable | Household appliances, industrial machinery | Long lifespan, low maintenance | Requires a consistent power supply |

| DC Motor | Direct Current | Precise speed control | Vehicles, robotics, and small electronic devices | High control precision | Higher initial cost |

| Brushless DC Motor | Direct Current | High efficiency, no brushes | Drones, electric cars, and computer cooling fans | Low maintenance, quiet | Requires controller complexity |

| Stepper Motor | Direct Current | Rotates in precise steps | 3D printers, CNC machines, robotics | Precise control for position | Limited speed and torque |

| Synchronous Motor | Alternating Current | Constant speed under load | Heavy industrial equipment, electric clocks | High efficiency, precision | Complex starting mechanism |

| Induction Motor | Alternating Current | Self-starting, rugged structure | Fans, pumps, compressors, conveyor systems | Cost-effective, durable | Lower starting torque |

| Universal Motor | AC or DC | Lightweight, high-speed | Handheld power tools, vacuum cleaners | Compact, versatile | Wears out faster over time |

| Servo Motor | AC or DC | High torque, controlled movement | Robotics, conveyor belts, camera systems | Precise, responsive | Requires complex controllers |

Common Applications of Electric Motors

Industrial Machinery

Electric motors, besides their crucial role in machines, also play a vital role in demanding tools such as conveyor belts, fans, pumps, compressors, and mixers. It ensures long service life and efficient work in any type of manufacturing plant or production line.

Household Appliances

The operation of most household appliances relies on the work of electric motors. This includes washing machines, fridges, dishwashers, vacuum cleaners, and air conditioners. Universal motors and induction motors are often the best options due to their performance and compatibility for small, repetitive tasks.

Transportation

Motors act as the heart of modern transportation, powering locomotives, electric vehicles, hybrid vehicles, and even aircraft systems with high efficiency, low emissions, and smooth operation.

Robotics

Due to their precise movements and control, servo motors and stepper motors find applications in robotics. They are found in automation systems, robotic arms, drones, and other precision machinery that require controlled motion.

Healthcare Equipment

The reliable operation of medical equipment, including ventilation, MRI, infusion pumps, and prosthetics, relies on the use of an electric motor. The availability of compact and quiet motors is essential in this area for ensuring patient comfort and safety.

Power Tools

Universal motors are ideal for lightweight design and high-speed functionality, and are therefore used in portable power tools such as drills, saws, grinders, and sanders. These tools have applications in construction, carpentry, and a wide range of DIY projects.

Importance of Quality Motor Parts

High-quality motor parts are essential for ensuring that any motor-driven device or system operates efficiently and reliably for years. Components fabricated from high-quality, durable materials, designed and manufactured to exacting standards, should significantly reduce equipment failure risk, minimize downtime, and maximize optimal performance, among other benefits. For instance, well-made motor windings will improve energy efficiency, and the ball bearings will reduce wear and tear that could increase a motor’s life span. These motor parts, used in the medical, automotive, and manufacturing industries, are criteria considered in performance standards and regulations for safety. In recent times, advancements in the study of material structure and significant progress in their manufacturing processes have led to the production of parts with higher thermal resilience, reduced noise, and enhanced power density, which are sought after by modern applications and technologies. Therefore, good-quality motor parts will not only function effectively but also be environmentally friendly by reducing energy waste and the need for frequent replacements, which in turn supports the overall performance and maintenance of the motor.

Essential Electric Motor Parts

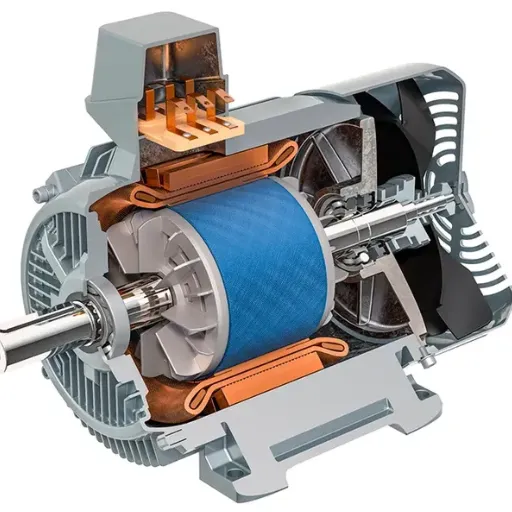

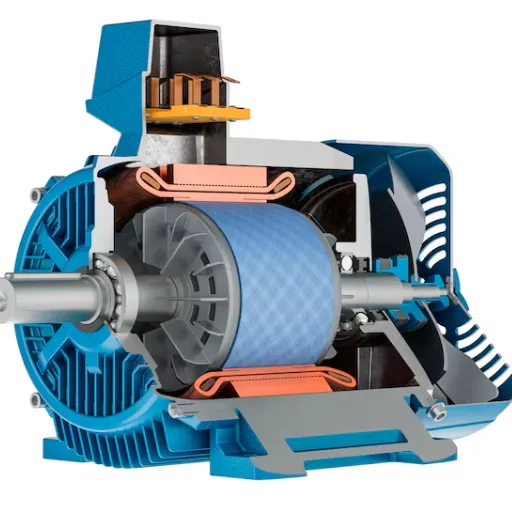

Rotor and Stator

The internal components play a crucial role in the functionality of an electric motor. The stator is responsible for producing a magnetic field and arranging it with the rotor. That causes the rotor to rotate, and mechanical energy is derived in the process. Interestingly, the name electric motor would be incomplete without including the stator and rotor together.

Bearings

Bearings hold the rotor while allowing it to spin smoothly and with minimal friction. Bearings not only prevent excessive wear and tear on the motor while it is operating, but also improve the efficiency and lifespan of the motor.

Windings

The windings are coils of insulated electrical conductors embedded in the stator core, forming the electromagnetic field when current passes through them. The winding specifications and arrangement have almost a direct influence on the motor’s efficiency and operational performance.

Shaft

The mechanical energy generated by the rotor is transmitted through a shaft to the fan blade, conveyor belt, or other such materials. The transmission system of a shaft should be strong enough to cater to the amount of energy generated.

Housing

The housing is a key component that protects the motor’s internal sections from external factors such as dust, humidity, and other foreign elements, thereby contributing to the overall durability and safety of the motor in various environmental conditions.

Key Components of Electric Motors

| Component | Description |

|---|---|

| Rotor | Rotates to create mechanical energy through magnetic fields. |

| Stator | The stationary part that produces a magnetic field. |

| Shaft | Transfers mechanical energy to the application. |

| Housing | Protects internal components from dust and debris. |

| Bearings | Support the rotor and enable smooth rotation. |

| Windings | Coils that generate an electromagnetic field when current flows. |

| Commutator | Ensures the current direction in DC motors for proper rotation. |

| Brushes | Conduct current between rotating and stationary parts in some motor types. |

| Cooling System | Maintains optimal operating temperature for efficiency. |

| Terminal Box | Connects the motor to an external power source safely. |

Replacement Parts Overview

Wear and tear can cause electric motors to deteriorate quickly; therefore, outside help in the form of electric motor replacement parts is of great importance. In particular, any motor that uses brushes will require brushes. Capacitors, whose application is primarily in starting D.C. motors, as well as all other motor types, need them in some way. This is actually one of the most common critical motor components, as it is used to either smooth out the power source or enhance some parts of the motor system. Motor capacitors can also be designed or created to alter the motor’s behavior in different ways.

The replacement of parts should consider compatibility, material quality, and the manufacturer’s statements. Good quality parts are not only meant to restore the engine’s performance, but they also exceed that by saving energy and improving the causes of low energy and accidents. Any operation will wear down the various machinery components at different rates due to factors such as temperature and friction, and some elements may need to be replaced even before they break down. Utilizing existing information enhances the capacity for rational decision-making when purchasing the most cost-effective and durable options.

Accessories for Electric Motors

Accessories that enhance the function and efficiency of electric motors can significantly transform their operation, enabling them to perform effectively in various circumstances. Of all the assessed helps, motor controllers and starters are significant for easy starting and effective control of speed. Other useful and often necessary accessories available include cooling fans and blowers, which are used to dissipate heat, thereby keeping the motor cool and operating at sustainable levels for an extended period. These accessories should not be placed in a situation that may lead to overheating the motor. Mechanical connection elements, such as shaft couplings and belts, will often support the transmission of power without any issues, whereas the use of vibration isolators will minimize mechanical damage to the system. Additionally, high precision is achieved due to the presence of encoders and sensors, which measure various system variables, including speed and position. The installation of such accessories in a proper manner will ensure that electric motors, as well as hydraulic systems, are capable of functioning and fulfilling specific requirements even under severe conditions, while remaining high-performing.

Shopping for Electric Motor Replacement Parts

Whether one is getting new replacement parts for electric motors, a fundamental question is: is this compatible, suitable, and reliable enough? With all that in mind, it is essential to first pin down your motor’s unique particulars, which include make, horsepower, and working voltage. Select your replacement parts from manufacturers with a good reputation across the market. Seek out suppliers or sellers who are well-reviewed and have a sufficiently good support system to respond to any queries concerning either the installation or use of the product. In case the hired parts do not meet specifications, remember to check the refund or guarantee that has been provided for the distrusted parts. Keeping up with trends and acquiring products from the right places helps extend the capability of your motor and its lifespan.

Where to Shop for Motor Parts

When purchasing spares for motor vehicles, it is essential to consider all available options and weigh their advantages and disadvantages. These could be either online or simple local neighborhood shopping venues. Automotive and industrial parts e-commerce platforms are great for finding the right motor parts, as they have a wide range of products to showcase and review from other buyers. They regularly update the product descriptions and reviews. This will ensure that maximum benefit is derived from product purchase. To assist in purchasing, manufacturers’ websites have become increasingly detailed, and with their assistance, consumers will be able to make more informed choices. Direct assistance in examining the part and purchasing it can also be obtained at local stores, such as hardware shops and car repair shops. Furthermore, some retailers or suppliers offer for sale parts with warranties and repair services. Online shopping aids and the bumpers do get in the way and enclose the areas of the order.

Factors to Consider When Choosing Replacement Parts

Compatibility and Fit

Carried out the replacement procedure when the part is on the fly and confirmed that the requirements of your specific automobile make and model with respect to that item are necessary. Refer to the user manual or consult an expert to determine if the part can be fitted. A misfit can not only mean wrong functioning, but could also cause damage to the machine.

Quality and Material

Assess the quality of the part and the materials it is made of. Some of the parts, such as those from the agencies, are focused on the car manufacturer and are mostly original and more reliable. Although different from the original car’s structural components, some other parts can be cheaper; however, their quality may also be inferior. Opt for parts with higher quality compared to case-based production, making your own that are equal to or better than the OEM.

Warranty and Support

Always check whether the part comes with a warranty. A good warranty will not only help you in the event of manufacturing defects, but it will also provide peace of mind in the event of other issues. When investing in an item that requires installation, consider how the supplier offers technical support.

Cost and Budget

Although cost plays a major role, attention should be paid to ensure the price does not exceed the quality of the services or products. When purchasing cheaper items, there is a possibility that they may need to be replaced or repaired soon, which can be more costly in the long run.

Performance Needs

High-performing vehicles, for example, those used in sports activities, are equipped with better brakes, while heavy-duty trucks have stronger components. To obtain such parts, evaluate your vehicle’s performance specifications before purchasing them.

Brand Reputation

Examine the brand’s history in production and performance. Find out all available information about the brand so that they do not specialize in the production of perishable parts. Italy makes further evaluations through reviews from past clients and approved users.

Quality vs. Cost: Making the Right Choice

Keeping up with industry changes, such as new technologies and their associated cost implications, remains a critical approach to providing the best quality as efficiently as possible. Knowing the latest prevailing developments ensures that you can discover the importance of some lesser-known goods or devices, as well as newer versions that maintain the same level of functionality but are more affordable. For instance, current developments in the field of materials science have resulted in the production of materials that appear to be cost-effective but hard-wearing, thus offering a significant improvement in the quality versus cost equation. The available figures on the use of a particular product over time, in view of, for example, its expected life cycle, can be used in what is known as the trays’ evaluation and can show improvement areas where higher expenditure now will save later. Incorporating cutting-edge technology and prioritizing all available measures allows one to balance the budget with the need to optimize quality.

Maintaining Your Electric Motor

To ensure the efficiency and longevity of its working condition, maintaining an electric motor is very important. The following are the maintenance tips as addressed:

- Regular Cleaning – Free the outer and ventilation points from dust, Fibres, and other materials. In addition to such action, prevent such electric motors from overheating or a reduction in performance. Use only a mild bristle broom and compressed air, and exercise caution when cleaning intricate parts.

- Inspect for Wear – Regularly check for wear and tear on the bearings, belts, and other components for any fluctuations. In cases of wear, order a new part rather than ignore, correct the circumstances and introduce more advanced technologies and materials.

- Lubrication – It is essential to apply the proper oil amounts at the recommended time intervals specified in the equipment manuals. It is necessary to minimize such additional forces so that the electric motor adhesive will last longer.

- Monitor Temperature – Railway parts suffer significant damage when they become excessively hot. It is therefore essential to monitor the motor’s temperature level periodically when the locomotive is in operation, ensuring it does not exceed the set temperature range.

- Electrical Checks – Verifying the proper installation, functional capability, and mechanical integrity of wires and connections. The faulty existences of an electrical component lead the device to operate improperly and almost always fails.

When such provisions are followed and the user’s manual is available, reaping the benefits of the machine’s high performance and avoiding downtime should be possible.

Routine Maintenance Tips

Lubrication Schedule

Other moving parts, such as bearings, require routine oiling to maintain their proper condition and prevent wear caused by friction. Different motors require different types of lubricants, and as such, one should be able to obtain information regarding the oiling within the motors annually. For example, many industrial motors require oiling every 3-6 months, while those engaged in heavy work may need to be oiled more frequently.

Inspection for Vibrations

Unusually, this also addresses some of the potential causes of issues, such as unbalancing, loose bolts, and belts, as well as dials that are not correctly set. Let me clarify a vibration shut-off mining system that offers recommended temperature fluctuations for regular equipment use, as excessive vibrations may impair the equipment’s useful life, allowing for better maintenance without destabilization accumulation.

Keep the Motor Clean

Electric motors can overheat and fault due to accumulated debris and pollutants. Dust and rust typically accumulate on cooling fins and air ducts, requiring maintenance via a brush or air shutoff several times a day. If possible, keep the space around the motor clean as well.

Monitor Electrical Load

You should regularly check the voltage and current of a motor and ensure that the values are within the recommended limits. There is an adverse effect on the life of a motor if it is overloaded. For example, a motor rated for 10A at 240V should be expected to only operate within ±10% of these parameters.

Inspect Drive Belts and Couplings

There are certain items, such as power transmission belts and couplings, that require inspection for worn-out, misaligned, or loose components. In the event of failures, these components must be removed or re-implemented to prevent further strain on the motor.

Test Insulation Resistance

During scheduled motor maintenance, an insulation resistance measuring device must be used to ensure the integrity of the motor’s insulation system for its correct functioning. Any manifestation of wear or reasons for a decrease in resistance after any repairs and/or rework on the motors can be detected and documented.

Signs You Need to Replace Motor Parts

It is essential to know how worn-out components are in advance to prevent breakdown. Destabilization noises that are generally not present, such as grinding, clicking, or buzzing, are also indicative of likely faulty bearings and other components that are most likely to fail. The machine is said to be working correctly when it is not deviating due to ability tremors, which is generally due to a mechanical or even chemical Mismatch between the parts, allowing them to work faithfully. This is a specific part, such as stator rotor windings, that exhibits over-the-top performance warpage. Conventional-aged France-related motor, additionally, one does not have to look so hard for its core temperature quantities to comprehend that cooling has declined tremendously.

On the other hand, in an operational state, the exaltation of heat that exceeds the parameters at stake, and only when cooling is on, is often a bad sign, more so. And, of course, the tendency to closely watch the breaker, where one keeps going to the generator or to this device, i.e., the transformer, or whose renovation is a result of many energy-related symptoms. These problems can further increase, thereby improving the importance of the golden period of motor equipment and processes.

How to Properly Install Replacement Parts

To ensure the lifespan and effectiveness of equipment are maintained, it is necessary to install repaired parts correctly. Please read the compliance and installation instructions for the factory-made equipment in your unit. Before beginning the assignment, ensure the power source is off. Put simply, any additional devices should be unplugged to limit the possibility of accidents in the near future. Inspect the new component for any potential flaws or imperfections before installation. Clear the area of any looseness, including filth, dust, or small objects, that could potentially cause problems with fitting the connection. Use the proper equipment for fitting a part and pay attention to torque and clearance, as these are essential for preventing the part from wearing out or dropping out. Fitting all components, conductive materials, and screws should be done correctly, without twisting, as it may lead to breaks and collapse. Perform a trial run to verify that all installation steps are completed correctly and the built-in part is functioning properly. Even in the initial part of the operatio,n watch the work closely, especially bearing unusual noise and movement effects that may point to misalignment. Carrying out the procedure with accuracy may increase the effectiveness of the equipment and reduce the likelihood of future problems occurring.

Specialized Services for Electric Motors

Improving the lifespan and maintenance of electric motors requires the use of several specialized services. These services involve restoring coils when they are destroyed a process known as, motor rewinding, and a process called dynamic balancing aimed at eliminating the vibration and maintaining wear. The same programs employed in the primary services are used to identify the early stages of equipment deficiency, such as bearing and insulation degradation, which can be corrected to avoid severe consequences. Laser alignment is also carried out to establish the precise spatial relationship between the electrical machine and the connected machines, thereby preventing adverse effects from external mechanical forces and ensuring optimal performance. The existence of the other services mentioned makes the electric motors more reliable because they reduce downtime, thereby extending the working time of all man-made apparatuses.

Finding Professional Repair Services

In the sphere of professional electronics repair, such as precision repairs for servomotors, picking the right provider is crucial. It is best to look for businesses with established reputations and well-trained staff that has gained experience on a large number of various makes of motors. The use of current-day diagnostic devices and a thorough compilation of the toolkit ensures both quick and proper diagnosis and repair jobs. Moreover, numerous decent service providers take it a step further by designing a customized preventive maintenance schedule to meet your specific needs. Reviews, comments, and papers, along with credentials, play a significant role in establishing the type of services offered and the expectations one should have towards them. It not only addresses the issue of why it is necessary to get the instruments restored but also goes further to highlight the relevance of the enhancement.

DIY Repairs vs. Professional Help

You may understand the above information to be a critical and highly relevant reminder in the quest to find the right repair procedures for your computer, particularly when considering the “DIY upgrade” method versus the “Get help” method. There are rewards and penalties associated with any policy intended as a compromise. Utilizing “Do It Yourself” repair often saves money and offers satisfaction, especially when relatively low-skilled interventions aided by basic tools are attempted. The introduction of the internet and various educational materials assists laypersons in taking on different fixes, including those that necessitate digital devices. This freedom embraces destructive health factors, which include the harmful expenses and risks.

On the other hand, hiring a specialist eliminates your need to do the dirty work, as it is one of their crucial responsibilities. Those technicians are well-informed about the root causes of a problem, and that reduces the chances of it recurring. Conversely, while they perform the repairs, they provide a guarantee for their work, assuring you. The initial cost may seem expensive, but the service’s dependability and trustworthiness will respond even more effectively to potential threats and losses. At the end of the day, it will solely be the decision, which again will be based on the amount of work to be done to repair the defect, the confidence you have in doing the job, the extent of damage that can occur in case the repair is not done for a long time, and the kind of components to be repaired.

Customer Support and Warranty Information

It is crucial to ask about customer service and the terms of warranty when deciding to use any services. It can be as simple as needing a hand each time and not being attended to, which makes one feel irritated. Whenever a person spends time waiting on the other end of the call, only to have the support representative assist them via chat, trust is broken. It is essential for the company to ensure accessibility and have professionally trained personnel available for all clients. Service providers who make such assumptions are considered to be lacking in customer loyalty, which they should strive to achieve. More customers are now being given resources that provide extended warranties and other benefits, such as free repairs or replacements within stipulated periods, which help target longer use. What does it mean to provide good support to the customer without going outside of one’s favourable position? Assessing how these concerns are addressed will help the client identify favorable conditions that align with high-quality back-end support.

Reference Sources

1. Vibration Analysis of Reconditioned High-Speed Electric Motors

- URL: Read the full paper

- Key Findings:

- The study developed a vibration diagnostic method to assess the quality of reconditioned high-speed motors used in manufacturing.

- It highlighted that reconditioned motors often fail to match the durability of new motors due to imprecise repairs.

2. Determining the Quality of Electric Motors by Vibro-Diagnostic Characteristics

- URL: Read the full paper

- Key Findings:

- This study focused on diagnosing the technical condition of electric motors in electric buses using vibration levels.

- The research demonstrated that reducing vibration levels by 8 dB could double the motor’s lifespan.

Frequently Asked Questions (FAQs)

Q: What are the most common motor parts used in repairs?

A: Everyday repairs often require items such as Brushes, Bearings, Gears, and Reds, among others. One cannot imagine any other way of ensuring the working conditions of Electric Motors of both types without these components. In more severe situations, it may necessitate a complete repair, including replacement of brake units, internal parts, and components. Therefore, it should be easy to identify the problematic part, remove it, and replace it to avoid any functionality issues. It is usually possible to purchase these parts separately, or they can be ordered along with a comprehensive set through the repair services that you might need.

Q: How do I know if I need to replace my electric motor?

A: Here are some reasons you should consider changing the electric motor: Unusual sounds, excessive heating, or decreased efficiency. If the motor fails to work every time you switch it on or you keep having to repair it, there is a high possibility that replacement parts will need to be sought. At the same time, if the motor becomes noisy or has been running for an extended period without proper maintenance, you may need to investigate further. It may also be helpful to inspect fan covers and mounts to determine whether there is an age-related overload case or if replacement will be necessary. It is always wiser to ask every competent evaluator to ensure that a considerate view of design is made without any haste.

Q: What is included in a motor repair kit?

A: A maintenance kit to refurbish the motor, more particularly, consists of the necessary elements to contend with known failures or deterioration. The sets will generally include, at the very least, two brushes, several bearings, and sometimes some inner elements and finished components dedicated to individual motor models. You may also have some gear reducers, adjustable motor stands, and other types of attachments, depending on the supplier. You can use easy-to-use kits when you are looking for something quick and effective without having to call various suppliers for different item parts. Always ensure that you obtain a kit that corresponds to the make and model of the motors, so that the parts can be fitted correctly.

Q: Can I repair my electric motor myself?

A: Sure, you can work on the motor on your own if you have the skill and all the tools required to carry out the job. However, it is extremely important to take the analysis of the skills in advance and the complexity of the repair needed. Minor fixes, such as replacing brushes or bearings, can often be tackled by fairly skilled Do-It-Yourself individuals. In some cases, the difficulty exceeds that of the basic ones, and for instance, a novice may not know how to work with the motors inside an air conditioner or a fan, which require the assistance of an expert. Also, ensure that the provided components are identical to the previous ones and install them, taking all necessary precautions into account. In cases where everything seems too complicated, one may want to engage an appropriate mechanical engineer to save time and prevent further destruction.