Generators play a vital role in the operation of industries, businesses, and critical infrastructure worldwide. However, it is unavoidable for their performance to decline if they are not well-maintained, as is the case with any other equipment. And this is why some professional generator rewind services find recognition. Such services encompass repairing a generator and improving its performance through the reinstallation of its ready-made windings, thereby assisting in the longevity and optimal operation and maintenance of the system. Essentially, this review provides insights into why generator rewinding is necessary, how the process is accomplished, and the impact of rewinding on the system in terms of its reliability and cost factors. Even if you are in charge of a commercial process or compliance systems, it may be beneficial to be aware of the benefits of engaging a skilled rewind generator service, so that you do not make costly decisions when trying to maintain operations.

Understanding Generator Rewind

Over time, the glue applied to the coil beneath these coils begins to change its appearance and melt. When this happens, the overall appearance of the coil can be affected drastically. Any light above when starting is supposed to show some, which never does. A standing time while the cylinder is on, repeats the process as if to burn all the remaining residues of the film, which are smoke-bound, left in the insulating spacer surface and the buffer wall before the business closes.

What is Generator Rewind?

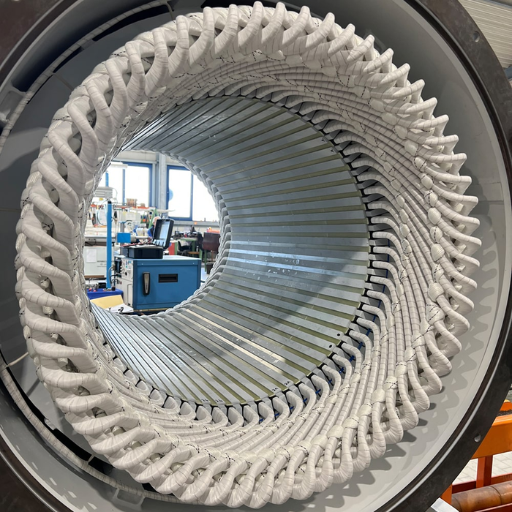

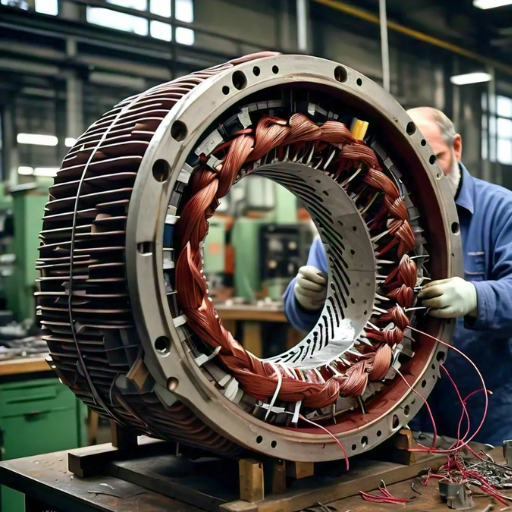

The process of disassembling an electrical device, such as a generator stator, and then mending or replacing the coils is known as the generator’s stator restructuring. Stators and rotors are machines that convert mechanical energy into electrical energy; therefore, they require repair when damaged. The setup of machines, such as generators used in power generation, involves numerous electronic systems; thus, it could break down beyond repair at any time. A typical generator after rewinding is supplied with new conductors within a core, and repair of the stator winding is completed. Such rehabilitation enables the construction of highly sophisticated, transformed machines, utilizing contemporary materials and technologies. This is a convenient and effective mechanism widely used by companies that rely on an uninterrupted power supply, allowing them to save substantial amounts of money that would be spent on the new installation of a unit.

Importance of Rewinding for Generators

Aspects of this kind, and mechanisms of generators in general, necessitate adjustments, among others, through maintenance. Failure winds’ services are finished, but it is internally charged, meaning that the generator’s power performance is impaired, which causes energy that would have been supplied to be dissipated, and continuity elements to avoid operational failures. The use of new technologies for Winding enables one to use new design insulating materials and wires of higher quality especially when it is impossible when a manufacturer gains experience, as well. Winding is specifically valuable for machines with bearing dynamics that have multiple stages, as it helps identify the weak zones whose useful life can then be prolonged. This policy also avoids sudden blowouts born of despair, as there is a backup in place. The plant does not necessitate total stoppages, which is crucial for industries that require working twelve hours a day or even twenty hours a day.

Overview of Key Components

| Key Component | Description |

|---|---|

| Insulation Materials | Improve thermal endurance and efficiency. |

| High-Grade Conductors | Enhance current flow and reduce losses. |

| Core Laminations | Minimize eddy current losses effectively. |

| Bearings | Ensure smooth rotation and reduce friction. |

| Cooling Systems | Maintain optimal operating temperature. |

| Shaft | Transfers mechanical power efficiently. |

| Windings | Convert electrical energy to magnetic energy. |

| Frame | Provides structural support and durability. |

| Commutator | Ensures direction of current in windings. |

| Brushes | Transfer current between stator and rotor. |

When Does a Generator Need Rewinding?

Generally, a generator requires rewinding when it exhibits negative symptoms of wear and tear that affect its operation. Often, this can result in high temperatures for extended periods, reduced performance, abnormal sounds, breaks in the windings, or even a complete failure to generate power. Factors such as the construction of the equipment and years of service gradually damage the insulation of the windings, hence the need for a generator rewinding to go back to normal. An inspection report can also be used to detect these signs and act to avert the probable damage that can be expected from the faulty aspects.

Signs Indicating Your Generator Needs Rewinding

It is essential to consider the resourceful nature of engine generators, as well as whether they require rewinding. Fault-type frequency of the circuit breaker, excessive vibration levels while operating, and excessive power output levels are a few identifying characteristics that indicate the need for rewinding a generator. More importantly, the machine should be examined for structural defects, such as a burning smell and a change in color around certain components, which could indicate overheating or insulation failure. In case, a possible condition where the generator takes time to start or its behavior becomes inconsistent is careful winding. Rewinding can be configured with failure and inspection, or handled by the user with recommended precautions, and data revised.

Common Issues Leading to Generator Overhaul

Worn-Out Bearings

With constant use, the bushings in the generator may undergo mechanical degradation, leading to premature bearing wear. The burning rubs the bearing surfaces together, which in turn increases the wear and damages both the internal components of the machine and the shaft. It is essential to conduct timely repairs to replace parts of the generator that have already deteriorated.

Insulation Failure

A generator must have an inbuilt system that protects it from electrical short circuits, so its operation will be without any difficulties. In addition, the insulation component of a generator withstands factors such as high humidity conditions and corrosive gases, which, when exposed to it, may cause the insulation to function poorly, leading to low domestic temperatures and potentially causing the system to switch off.

Contaminated or Degraded Fuel

Poor fuel quality, including the use of fuel contaminated with carbon, would also have the following consequences. Rust appears with restricted injectors and engine speed, resulting in misfires and unsteady operation, which makes the entire genset overhaul inevitable.

Voltage Regulation Issues

If the regulator does not function, the voltage of the generator can be too high or too low. This may lead to the equipment connected to the generator spoiling. It includes general wear and tear is also connected to the generator. It helps experts identify or correct flaws early enough to avoid their aggravation.

Corrosion and Rust

In the case of generators used in the most severe environmental conditions, such as those with high humidity or salt, they will generally corrode or rust. This is likely to compromise the mechanical strength of the generator components. Even with the construction standards and the lack of electric terminals, the operational age of the generator can be shortened.

Overloading the Generator

Too much load on the generator’s operation also has its share of problems associated with it. When the voltage is inadequate, many tend to run the generator. This is wrong when handling loads in that way. In fact, it is the reason for overheating, wear and tear to the internal changes, and most especially, it can ruin the windings. To mitigate this damage, there are factors that can help avoid the common problem.

Assessing Generator Performance: Power Output and Lifespan

The potency of the generator is crucial to the range of its output power and its life cycle expectancy. When to refer to Power Output, how does one measure the power of a generator- In kilowatts (kW). The power output indicates how easily or often the generator serves the equipment without interruption. Evaluating power output, advanced test methods assess a generator’s capability under various loading conditions to ensure it can sustain peak performance. For efficient power delivery, preventive maintenance, which includes multiple types of load tests and calibrations, is indispensable.

However, the lifespan of an individual generator also depends on factors such as the quality of the design, usage pattern, and gross labor intensity. In this regard, it is worth noting that generators built with proper equipment and dissipation systems usually do not deteriorate easily, even when used in harsh environments. In addition to this, complying with the maintenance regulations, timely renewal and replacement of the parts as they wear later on, and using the generator within the prescribed limits help significantly in improving the generator service time. Some statistics suggest portable generators typically range from 1,000 to 2,000 operational hours at most, while those of industrial caliber can reach up to 10,000 hours with regular maintenance. If these levels are carefully observed, the professional experience of engaging with the power products will be enhanced in every possible way over time.

The Rewinding Process Explained

In a generator, the rewinding procedure involves restoring or reconstructing the stator or rotor coils that have been damaged or are not functioning effectively. Generally, the process begins by carefully removing the defective or burned-out bars and cleaning the inner part of the core structure. Further, the new conductors with the desired slot mid-skin are placed within the core according to the machine’s construction specifications. It concludes with the process of concatenating machine-installed incinerators in each phase or winding, and the procedure known as insulation, which protects and ensures the system’s serviceability and protection from electrical breakdowns. To complete this chain of processes, the equipment should be subjected to tests that help determine whether the machine’s operations are normal and whether it is cost-effective. Thus, this process enhances the performance of an electric generator and extends the machine’s usefulness.

Step-by-Step Guide to Generator Stator Rewind

Initial Inspection and Assessment

First things first, please refrain from any improper behavior. Then it would be better to observe the generator resurfaced by the rotor. Probe the condition of the windings, the insulation, as well as the core by using relevant tools for a precise diagnosis, and hence, the degree of the ‘laminations’ requiring replacement can be assessed.

Dismantling and Cleaning

Having completed the specified activities, that is, the assessment, start disassembling the stator and remove the old windings. Clear the slots in the core of any other foreign matter, such as dust, salt accumulation, worn-out asbestos winding insulation, and debris after the removal of burnt copolymer. This is to leave a fine finish for the new windings.

Core Testing

Analyze the core, such as using loop or core loss tests, to identify internal damages, including breaks or sections within the core. Solving this issue and other niggles related to rewinding before rewinding will help to improve the performance of the generator and its shelf life as well.

Preparation for Rewinding

Select the conductor with the correct gauge and insulation that matches the generator’s design and rating. Ensure that all products conform to the required standards of voltage and heat, as measured in terms of industry resistance.

Winding Process

Pay attention to how the new windings are introduced into the frame by carefully placing wires in the relevant core slots, based on the original design. It is essential to ensure that the tension is similar and that the windings are evenly distributed to avoid any overpressure on any portion of the generator and also enhance electrical efficiency.

Application of Insulation

Insulating the windings with durable, high-quality materials that protect them against both electrical short-circuit faults and environmental effects is essential in the design. Adequate insulation is also an absolute necessity to produce a safe installation and minimize the chances of an electrical fault arising upon commissioning or recalibrating the equipment during manufacture.

Reassembly and Testing

Before installation, make sure to reassemble the armature and secure it back into its proper position. Carrying out both mechanical and electrical examinations of the device is mandatory, which includes resistivity, type of insulation, and load-bearing capacity tests to assess how well the construction work was done.

Final Inspection

A final inspection may be conducted on the work to ensure that everything is in order and all system components are properly fixed and functioning correctly. Record these findings for subsequent maintenance activities and assess all measures that indicate the generator’s readiness for the next application phase.

Field Rewind vs. Motor Rewind: Key Differences

| Parameter | Field Rewind | Motor Rewind |

|---|---|---|

| Purpose | Repairs generator field windings | Repairs motor stator windings |

| Primary Application | Electrical generators | Electrical motors |

| Key Component | Field poles or rotor windings | Stator or rotor windings |

| Voltage Handling | Typically higher voltage capacity | Usually lower to medium voltage capacity |

| Complexity | Higher due to intricate field configurations | Moderate complexity |

| Testing | Requires load and insulation tests | Focuses on continuity, insulation, and load tests |

| Maintenance Tools | Specialized tools for field winding bonding | General tools for motor winding repair |

| Time Required | Longer due to specific adjustments | Comparatively shorter |

| Skill Set Needed | Advanced expertise in high-power systems | General expertise in motor systems |

| Common Industries | Power generation and utility sectors | Industrial machinery and manufacturing |

Benefits of Professional Rewind Services

Electrical motor rewinding services have numerous benefits that guarantee the reliability and efficiency of electrical motors.

- Extended Equipment Lifespan – Due to the repair of this damage or wear in the gears, rewinding typically restores regular operation and prolongs the motor’s lifespan, thereby reducing the need for equipment replacements.

- Improved Performance – Typically, expertly rewound motors perform at optimum levels of efficiency, reducing energy consumption and operational costs.

- Cost Savings – Professional rotating has taken on the role of plant floors, generating cost savings that are realized elsewhere, while considering the circumstantial merits of each approach or redesigning equipment within the existing structure.

- Minimized Downtime – Skilled electricians also complete rewinding in a quick turnaround and share techniques to help industries regain engine status in less time.

- Custom Solutions – Rewinding services are specifically designed to address the unique needs of the user, taking into account that certain conditions cannot be met without modifying the winding design configuration.

Seeking rewinding services from highly trained experts helps an organization achieve positive results that enhance the equipment’s performance and productivity.

Improving Efficiency and Reliability of Electric Motors

To reduce the cost of running and extend the lifetime of electric engines, it is essential to emphasize improving their efficiency and quality. By taking steps such as routine lubrication, alignment checking, and regular maintenance with inspections, it is reasonable to ensure that motors will last longer than their lifespan. Otherwise, upgrading through the use of energy- and performance-efficient motor designs, achieved by replacing parts with contemporary components, is also effective. In the modern world of technology and energy, it is now possible to support such improvements. Moreover, industries such as automotive have implemented automatic monitoring systems, including IoT devices, which enable the analysis of symptoms and severity of motor failure before the motor fails. In addition to this, correctly choosing the power criteria and its load utilization helps to strengthen the device to interact directly with the equipment and complete the entire task while minimizing power wastage. Renewing electric engines, however, through trusted practitioners who use only approved materials, will restore the engine to its original condition and lead to improved performance compared to the initial design. These tactics, combined, made it possible for companies to conduct their business safely and reasonably conserve energy resources in the long run.

Cost-Effectiveness of Regular Rewinding versus Replacement

From the perspective of economic efficiency, repairing a motor or buying a new one is viewed from various angles, which help you make informed decisions. It is relatively cheaper to fix a used motor bearing, keeping in mind that it calls for less financial attention as opposed to buying a new one. Moreover, the recent advancements in technology and the development of winding and insulation materials have progressed to the extent that one would want to operate in peak condition, if not better, due to their high efficiencies.

Additionally, this would necessitate a motor replacement if it is outdated, inefficient, and underperforming in terms of results. However, the new models will likely have improved features and higher efficiencies. They come at a greater cost upfront, and there are various additional costs, such as change management and other issues that may arise with the modern motors due to technological advancements. However, an examination of the matter reveals that where motors are genuine, that is, less than 20 years old and still in good health/ structure, the cheaper and safer option for the environment is to rewind motors. This is more specifically the case when it is carried out by competent personnel who use high-quality materials.

Extending the Lifespan of Your Generator

Insofar as you do not stop using the generator, to make such a generator serve you for quite a long period of time, it is of the essence to carry out the proper maintenance. Consistent checks and proper maintenance are essential for detecting and correcting minor faults before they can develop into more significant problems. For instance, a typical deployment includes the cleaning of primary elements, such as air filters, fuel systems, and exhaust partitions, which are primarily the exhaust ones, as well as other design components that direct the exhaust ports and regulate fan noise generation devices. Periodic maintenance, as specified by the manufacturer, and the use of specified fuel and lubricants will help prevent excessive wear and tear on the internal components.

The continued progress in techniques for handling power-producing devices has made the work of performance evaluation easier. It falls under new areas. Installation of maintenance technology in the generator, tracking usage patterns, temperature changes, power generated, and other appropriate control measures to improve the performance of the generator. Moreover, equipped with a surge arrester, load management ensures non-infringement of excessive use of both the generator and the equipment. It tells us that the usage of the generator and its attached equipment can be evenly spaced throughout the time it is in operation, so that in the end, the life of the equipment is not shortened. There exist measures that will improve both systems and ensure that, at no point and at any given time, the power will go off, allowing the price of the generator to be realized.

The Value of Generator Rewind

Regeneration work is not a new concept in this area, and the regeneration of a device’s equipment, especially for generators, has been steadily advancing to achieve the highest performance efficiency. The aggravated internal conditions, such as operating features that include excess mechanical forces, currents, and temperatures, ultimately wear down the device overall, resulting in a reduction in performance accompanied by increased power demand and a higher likelihood of failure. This is when rewinding enters, as it simply requires replacing worn or faulty winding parts; therefore, the generator will be able to continue utilizing the wind power at an optimum level. Consequently, it not only prolongs the use of the generator but also reduces the significant costs associated with downtime. For some antiquated systems, it may be cheaper to redefine a rewind than to purchase an entirely new apparatus, and this will completely rectify the hummer programs, which will in turn ensure uniform functioning and mechanical output of the power.

Final Thoughts on Generator Maintenance and Rewind Services

One of the most essential activities in maintaining the generator is the service and rewinding of parts. Preventive maintenance protects against the development of small or significant damage, which can lead to much more expensive malfunctions. Manufacturers typically recommend rewinding as the most cost-effective economic solution to repair a generation unit that cannot be replaced due to wear or damage. Studies have shown that, with proper operation, even the most complex and expensive equipment can have its lifecycle extended by up to 50%. This fact justifies the recovery of such expenses and foresees much less unpredictable failures. And finally, advanced maintenance, however good it may be, is complemented by the performance of all ordinary maintenance activities to assist in achieving efficiency and safety during operation. By relying on the services mentioned earlier, businesses can manage operational risks and plan for possible electricity requirements in emergencies.

Actionable Steps for Generator Owners

Schedule Regular Maintenance

Lay out a reliable plan for power-generating equipment maintenance in collaboration with the company that sold you the unit to ensure safety and enhance performance. Changing the oil and performing other oil service tasks, refilling coolant, and cleaning filters are known to improve performance and extend the machine’s lifespan significantly.

Perform Routine Load Testing

From time to time, revise or alter the system for a capacity test to any extent, with its operation serving as a generator in the event of a fault in the electricity connection. This action helps eliminate potential shortcomings in advance and prevents their escalation.

Inspect for Wear and Tear

Each part of the generator should be inspected frequently, with special attention to consumption, including damaged wires, cables, and fittings. Interpreting these findings and taking the necessary action may save costs and prevent system breakdowns in the future.

Monitor Fuel Quality and Storage

In addition, one must ensure the quality of the fuel used by maintaining cleanliness during storage and ensuring that fuel supplies do not lie idle for too long. Dirty fuel can lead to inefficiency in your expedition, which in most cases results in engine breakdown.

Upgrade to Remote Monitoring Systems

It is a good idea to consider adding remote monitoring technology to your generator, allowing you to view various sections of the generator linearly. With this, you can keep an eye on performance metrics and also be alerted whenever any malfunction occurs, thus mainly ensuring all the time availability to the machine.

Stay Updated on Manufacturer Guidelines

Adhere to the manufacturer’s service and component replacement prescriptions. This will enhance the effectiveness of the equipment and minimize problems that arise from non-compliance.

Prepare for Seasonal Challenges

Seasonal conditions should result in changes to the maintenance schedule. This could involve precautions such as block heaters or winter fuels in the event of low winter temperatures.

Reference Sources

-

Optimizing the Refurbishment Process of Old 44 MVA Hydro Generator

- Summary: This study focuses on refurbishing a 68-year-old hydro generator. It explores alternating winding types and their impact on vibrational behavior. The research highlights the importance of selecting appropriate materials and techniques to extend the generator’s lifespan while maintaining operational efficiency.

-

Improving 20 kVA Generator Power Performance by Rewinding the Stor Conductor Windings

- Summary: This research investigates the rewinding of a 20 kVA AC synchronous generator to enhance its power performance. The study demonstrates how specific rewinding techniques can improve efficiency and reduce energy losses.

Frequently Asked Questions (FAQs)

Q: How does rewinding improve the performance of an electric motor?

A: Replacing the old windings with insulated winding coils appears to be quite effective. This can be done by providing the winding data to a rewinding process where the winding technician adds all current data to a new sheet. Video a 4k daigo of capacity current rates that do not exceed suitable permeable covering resistance current rates. Generally, replacing the insulation of the stator winding is the major cause of motor failure. Hence, the stator winding must be insulated by an alternative method other than varnish insulation. Motor stator windings with flexible toothed stator mounting arrangements were found to be more vulnerable to such failures. Also, aboard, electrical machines were drying out._current worked only to the will of this journal.

Q: What are the signs that a generator needs rewinding?

A: Several signs indicate that a generator has to be rewound. These include unusual noises, overheating, decreased power output, or frequent tripping of circuit breakers or other protective devices. If such thoughts come to mind, such as power cuts or temperature increases, it is of paramount importance to check the health status of the wires. There are checks that a technician can perform to identify which part of the machine requires rewinding: the stator or the rotor. In the same vein, as protection breaks down or the air gap becomes ineffective, a rewind can be used to bring the generator back to its original state.

Q: What is included in a professional generator overhaul?

A: Usually, a professional overhaul of the generator comprises inspection and measurement of all generator components, including the stator and rotor. During the overhaul process, insulation resistance is measured, surfaces are cleaned, and working parts are replaced if necessary. Additionally, if required, the generation of rotation force will be restored, as discussed in this process, which will involve replacing the old working windings with new, improved materials. These activities may also include ensuring that the generator produces the expected electric power output artificially, ‘under load’. Quality control during these activities is essential to ensure that the generator can perform its functions reliably over an extended period.

Q: Can you explain the role of the stator and rotor in a generator rewind?

A: The stator and rotor serve as crucial components in the functioning of a generator, and their condition must be observed when, during a re-wind, several parts of a generator must be repaired or otherwise done. The stator is the part that contains the winding coils in the stator slots, which establish the magnetic field. The rotor, in turn, rotates within this magnetic field, generating electrical energy. Therefore, during generator re-winding, the focus lies on the stator slots, which may have to be rewound due to damaged coils and insulation failure. This is important in terms of operations as it enhances the efficiency of the equipment and provides the assurance of reliability due to the design and build quality of the equipment.