Electric motors are the focal point of innumerable modern-day machines and equipments. The extent to which they are used in applications ranging from the household to industrial scale is significant. This article examines how electric motors work, the development of their components, and offers guidance on making informed decisions regarding component repair and maintenance practices. Therefore, this justifies why it is proper for one to learn about the various elements that will enhance the lifespan and performance of the electric motor.

Brief Introduction to Electric Motors

An electric motor is a device that transforms electric energy into mechanical energy. These same electric motors power various appliances, small engineering items, and other devices. An electric motor conventionally operates through magnetic principles, where whenever a current (electric) passes through a magnetic field, a force field is created. The demand for these electric motors in the household, automotive, and industrial sectors is high, as they offer a high efficiency rate and long service life. Construction-wise, it primarily comprises the stator, rotor, and controller assembly, which are essential components for the efficient operation of electric motors. Such parts must be well maintained if high reliability and longevity are to be achieved.

What is an Electric Motor?

Electric motors, on the other hand, operate by converting electrical energy into motion through the principle of electromagnetism. Specifically, the field set up by the stator and the current flowing in the rotor tend to repel or attract each other. This pushes the rotor to move, causing it to move. Current electric motors are more efficient and can be considered highly engineered, with AC motors predominantly influencing industrial applications. In contrast, DC motors are more favored in situations where speed control is required or accuracy is crucial. A few examples of late technology acquisition consist of brushless DC motor and synchronous motors for their improved cost efficiency, quietness, and low motor maintenance design, and hence dominant in, for instance, eco-friendly energy and EV automotive megafields. This development further illustrates the ever-changing character and applications of electric motor technology.

Importance of Electric Motors in Various Industries

In numerous fields of activity, electric motors are of paramount importance, serving to introduce various features and enhance the efficiency of processes inherent to any set of objectives of the present type. For instance, they power machinery and automated guided vehicle systems in factories, enabling refined manufacturing processes and above-average throughput. Almost all kinds of transportation have also largely adopted the use of electric motors, especially in the era of electric vehicles, which are both powerful and efficient, requiring suitable motors for both performance and energy considerations. Along the same lines, for power generation from renewable sources, electric motors are essential components, such as those used in windmills and watermills, which are utilized in hotels and effectively convert natural resources into energy with minimal harm to the environment. Brushes, for example, aim to expand the applications of motors beyond potential solenoids to robotics, medical, and home automation systems through the use of higher energy densities and power control capabilities. Regarding their wider utilization and the dynamic nature of their development, it is fair to say that electric motors stand as a towering presence in the industrialization of the world, as they continually promote not only efficient work but also innovation.

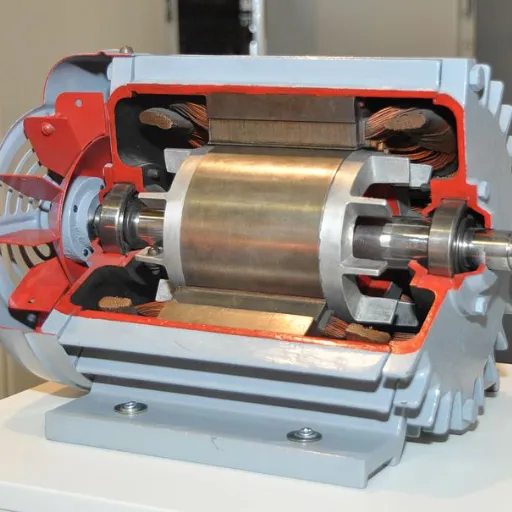

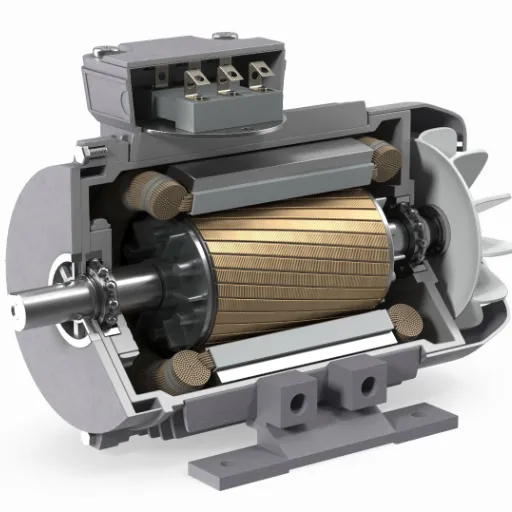

Overview of Electric Motor Parts

| Part | Description |

|---|---|

| Rotor | Rotating part generating mechanical energy. |

| Stator | The stationary part produces a magnetic field. |

| Shaft | Supports rotation and transfers mechanical power. |

| Bearings | Reduce friction, support the rotor’s motion. |

| Windings | Coils of wire generate an electromagnetic field, which in turn generates an electromagnetic force. |

| Commutator | Directs current in the appropriate rotor windings. |

| Brushes | Transfers electrical current to the commutator. |

| Frame | Provides structure and protection to components. |

| End Bells | Support bearings and align the rotor and stator. |

| Cooling System | Prevents overheating with fans or liquid cooling. |

Key Components of Electric Motors

- Rotor and Stator: The motor does not move without the rotor, while the stator refers to the stationary part where the rotor converts electrical waves into mechanical kinetic energy.

- Bearings and End Bells: The second function of bearings is to minimize the friction between the rotor and the stator. One of the advantages of welding the end bells to the casing is that it aligns the rotor properly through the bearings.

- Windings and Commutator: It also eliminates the shorting inconvenience that would occur when the pole winding, with a large number of coils, is energized.

- Brushes: These are devices used to connect an electrical circuit when they make contact with a rotating surface.

- Cooling System: It maintains the motor’s temperature, allowing it to operate for a longer time without issues.

The Stator: Function and Importance

An electric motor is a vital piece of machinery used in nearly all industries. What are the functions of the stator? What is the stator? How is the stator made? What is the stator in a motor? What happens when you run current through the windings in the stator? It is how the stator and rotor work to produce rotary motion, or the engine that provides the rotation. To minimize the reduction of the rotor’s output power due to excess heat loss, modern stators may incorporate more efficient materials and also techniques when being designed and constructed. All the developed and improved stator insulation technologies, coupled with proper designs, enhance the overall performance of the stator and improve its thermal stability, particularly under harsh conditions such as those caused by halogen gloves.

The Rotor: Types and Applications

The rotor is a key component in the operation of an electric motor, as it is the part that moves and transfers energy to create mechanical output. Typically, there are two main categories of rotors used in electric motors: squirrel-cage rotors and wound rotors. The squirrel-cage rotors consist of conductive bars connected to bars and rings on both sides, making them less complex to manufacture, more durable, and best suited for heavy-duty applications with minimal breakdowns. While wound rotors utilize inertial winding loops, similar to those in stator construction, and incorporate an additional resistor circuit, which enables speed and torque regulation, making them suitable for various types of machines that require dynamic response.

Rotors have many uses. For instance, in heavy machinery such as fans, pumps, and conveyor belts, squirrel cage rotors are widely utilized because they offer the highest operational efficiency in single-speed systems. Then, in heavy-duty areas like lifts and lift motor drives, wound-rotor motors are commonly used, as precise speed control is achieved. Due to the introduction of advanced materials, which are lightweight, and the use of improved cooling techniques, such as cooling flow enhancement, hunting fans will remain relevant and valuable for applications in engineering and industrial systems, as they have been for many years in the history of rotational machinery.

Understanding Windings in Electric Motors

One of the central elements in the design of electric motors is the wire winding. It is essentially through a winding that the electric motor generates a magnetic field for its working purposes. On the whole, Copper or Aluminum draw wire is used, and either strands or sections of these wires are wound individually in the motor casing, i.e., the stator, with an insulator placed at every layer to increase efficiency. There are mainly two types of windings in electric motors: stator windings and rotor windings. Stator windings are installed in a fixed position and provide the magnetic field, while rotor windings come into contact with this field and induce rotation. Recent technological developments have increased significantly in modern times, including more reliable insulation materials, effective heat management techniques, and well-equipped winding machines, all of which have contributed to improved system performance in terms of resistance. These improvements have enabled electrical motors to operate efficiently even under strict environmental conditions, with reduced energy consumption, making them highly applicable in numerous settings, including industries such as mining and vehicles.

Common Electric Motor Parts and Their Functions

Rotor

The rotor is the revolving part of an electric machine that moves within the machine and is responsible for delivering mechanical power through interaction with the magnetic field created by the stator.

Stator

The stator in an electric motor is the part that remains fixed, housing the windings or coils that create the magnetic field necessary for the rotor’s movement as the electrical current flows.

Bearings

Bearings provide support to the rotor, enabling its smooth rotation and reducing resistance to the equipment’s operation. These bearings will ensure the proper functioning and long service life of the motor system.

Shaft

Shaft, conceivably a part attached to the rotor, functions between the rotor’s outer ends and an adjacent piece of equipment or part, as may occur in the case of belt-driven conveyors or fans, for example.

Housing

The enclosure protects the machine by forming a protective covering that protects the machine’s internal components, as well as its structure, from the effects of dust, liquid, and mechanical shocks.

Commutator (in DC motors)

The commutator comes into service exactly at that moment to reverse the current flow through the rotor winding, ensuring smooth and continuous rotation in one direction in the case of direct current motors.

Windings

Windings refer to copper or aluminum wires that are twisted around the stator or rotor. When electricity is applied to the windings, they generate sufficient magnetism to enable the motor to run efficiently.

Brushes (in DC motors)

Switches keep the current flowing through the rotating wire coils in a DC motor by delivering it to the brushes.

Bearings: Types and Maintenance

| Type of Bearing | Key Features | Applications | Maintenance Tips |

|---|---|---|---|

| Ball Bearings | Low friction, high speed | Machinery, electric motors | Regular lubrication, inspect for wear |

| Roller Bearings | High load capacity, reduces rotational friction | Conveyors, heavy machinery | Ensure proper alignment and clean regularly |

| Tapered Roller Bearings | Handle radial and axial loads efficiently | Automotive, industrial equipment | Check for contamination, use the correct grease |

| Needle Bearings | Compact, low sectional height | Gearboxes, pumps, and small spaces | Avoid overloading, replace damaged needles |

| Spherical Bearings | Self-aligning, handle misalignment | Agricultural equipment, cranes | Monitor for cracks, maintain lubrication |

| Thrust Bearings | Manage axial loads in one direction | Fans, turbines, automotive clutches | Periodic inspection, to prevent overload |

| Magnetic Bearings | Contactless, frictionless rotation | High-speed applications, turbines | Monitor the stability system, and clean the system |

| Plain Bearings | Simple design, low cost, versatile use | Hinges, sliding doors, and construction | Grease frequently, and ensure the hardware condition |

Commutators: Role in Motor Function

Commutators, machined from copper blades and equipped with separate commutator segments mounted on the rotating system, particularly DC motors, are a significant part of commutators. When the brush passes the frame area of the coil, which has a commutator mounted on the rotating part, reversing the direction of the arcing is created. The “commutation” operation, as it is known, is mainly responsible for efficient transformation of electrical to mechanical energy in a motor. Commutators, in particular, are made of materials conductive for electricity (typically copper) and consist of separated strips provided with de-embedding bars that are connected to the windings of the armature. These ingenious Bartekas pieces, along with the carbonaceous appearance elements, also remain in malaria control, ensuring that only electrical glancing is breached. Higher performance and increased longevity that meet the advertised expectations of commodities, such as industrial machinery, cars, and consumer goods, have been achieved through the redesign of the commutator. For optimal performance and extended usage time, correct servicing, which involves cleaning and repairing damage or unevenness, is essential. They continually service the system; however, if necessary, it is more effective to replace broken elements, such as armature brushes, and ensure the operation of the motor that has not broken down.

Motor Replacement Parts: What You Need to Know

When changing vehicle parts, the primary focus should always be on additional functional elements that have a direct impact on performance and reliability:

- Brushes – These components often cause problems when they wear out, as they hinder regular motor operation. Get a suitable high-quality type that suits your combustion engine.

- Bearings – Ensure that the bearings working in the motor are in good condition, as worn-out bearings produce noise and vibration. Replace the worn-out bearings, and you will have a smoothly operating motor.

- Commutators – Definitely examine whether the surface is smooth and check for any damage. Remove the commutators and clean or replace them if necessary to maintain optimal electrical contact.

- Seals and Gaskets – As long as the seals are replaced, there will be no ingress of dirt into the motor components that require protection. Additionally, any cracked gasket will need to be changed soon.

- Armature and Coils – In the event of a motor blowout, please inspect the armature and winding components to determine if they are in poor condition and replace them if worn out.

Checking the manufacturer’s guidelines regularly and updating the parts according to the recommendations is essential for ensuring compatibility and extending the motor’s lifespan. However, during all this, the most important aspect is safety. So, this is when replacements are not an exception.

Identifying When to Replace Parts

Allowing them to wear out completely results in outages, which hampers further equipment usage and repair. Especially, loud operating mode and overheating are harmful, and they occur because the performance standards have declined. For example, when the bearings generate a growling or screeching noise, it is advised to replace them immediately, as this could be an early indication of wear or misalignment. By the same token, the commutator’s surface may not touch the brushes because the brushes quickly wear out or, in some cases, are even broken, and therefore the former can be replaced. Vibration values are valid when such concerns are raised, particularly where irregular or excessive motion could be related. These teachings and the practice of proactive maintenance can therefore prevent equipment failures and operation mishaps even in critical environments.

Choosing the Right Replacement Parts

Therefore, it is crucial to avoid mistakes and obtain the exact components for the engine unit whenever possible. This means that when removing particular parts, much attention should be paid to the model and the manufacturer of the motor. For devices such as bushes, bearings, or gaskets, it is necessary to look up the part number and manufacturer to obtain the correct size. These factors, coupled with their reasonable price, encourage more purchasing; however, realistically speaking, such design features should reduce wear and degradation. Additionally, the use of new parts, if they are within the design, is beneficial for some components, as most manufacturers have developed improved designs that reduce the risk of failure. Missed identification of the part used and delays due to new technologies will significantly impact the purchase of components in the market, which will compromise or decrease the reliability and performance of the electric machine.

Cost Considerations for Motor Replacement

When evaluating the cost of motor replacement, it is essential to consider several aspects, not just the upfront costs. The cost of the motor can be very affordable during installation, depending on its type, size, and brand. This is, for example, some premium motors have high efficiency motors and additional characteristics, such as’ advanced features,’ with a higher initial cost but justify their worth by reducing the power consumed in the process. Among the expenses incurred, also factor in the cost of Installing, which includes employing qualified personnel or making any modifications to the currently available systems. Lastly, consider the total cost of installing the motor, including usage over a given period, as well as maintenance, replacement, and energy costs. This helps even more if the company opts for an energy-saving motor, as there are numerous energy rebates available for such a motor. These aspects ought to be worked through so that a solution exists that is pocket-friendly and at the sme time beneficial in terms of performance.

Electric Motor Repair: Best Practices

Identify the Problem

To begin, one needs to understand the problem by conducting a visual inspection through the process of elimination. Possible concerns that may indicate issues include making noise, overheating, or operating slowly, among others. The help of multiple gadgets, such as multimeters or thermal cameras, can aid in identifying the issues that are prevailing, whether mechanical or electrical.

Follow Safety Protocols

Whenever working with the device, cut off power to the motor. Take personal protective equipment (PPE) into account while rescuing in motor component repair safety.

Inspect Critical Components

Inspect the motor shaft, windings, and terminations to dismiss any evidence of any physical detriments that might persist. If any defects are found, they must be replaced or repaired to restore the motor’s functionality.

Clean and Lubricate

Get rid of any dirt, water, or any foreign materials that may be in the motor casing. The moving surfaces must have a sufficient amount of grease to reduce friction and enhance the performance dynamics of the motor.

Test the Motor After Repairs

After cleaning them, reattach them in an orderly fashion, ensuring that there are no loose terminations. It is also advisable to confirm that the motor starts as intended and operates within its capacity before reassembling it in place.

In this way, it is possible to increase the operational life of the motor and enhance its performance without incurring any significant downtime.

Repair vs. Replacement: Making the Right Choice

Whether to repair or replace the motor depends on several factors, including its cost, age, efficiency, and the operating conditions under which the machine will be used. In many cases, minor repairs are done because it is cheaper to pay for this work rather than procure a new motor or extend the life of the espresso machine. All this work also protects against wear and tear, ensuring that the machinery performs optimally when necessary, without incurring any costs that may arise from repairs.

Conversely, if the motor is aged, experiences frequent breakdowns, or today performs less efficiently than the currently available motors, changing it might seem more logical. The fact that the new motors have additional benefits such as reduced power bills and greater durability, among others, can also be used to justify their increased cost. Besides, some energy-use policies and standards will necessitate the replacement of existing motors in some sectors.

To make a more informed decision, all costs that are likely to be incurred over the motor’s life should be reviewed, including fixed costs such as maintenance, variable costs represented by energy usage, and costs expected due to downtime. Acquiring a professional perspective and utilizing additional resources in conducting a cost-benefit study can help determine the best solution applicable to a project’s specific requirements.

Tools and Techniques for Effective Electric Motor Repair

For electric motor remediation services to be effective, one of the keys to obtaining ‘success’ is the availability of the instruments that are aimed at primary source identification and eradication. One such device is a multimeter, which is a standard tool used in power supply laboratories to enable measurement of the quantities mentioned, thereby helping to identify the problem. Yet another crucial tool is the combination, which is widely popular and also known by another name: megger usage for insulation resistance. Megohmmeters measure high resistance, are black lacquered, and can provide false readings due to low resistance errors. The device, powered on and off rapidly, will pick out the motor stator cores that are more resistant to corrosion. Megohmmeters are suitable for various tests, including the polarizing index and dielectric absorption ratio tests.

A task for skilled experts involves troubleshooting electric motor problems over an extended period. Accurate disassembling and cleaning are the early preventive measures done to curb pollution, or rather, repair problems. Another measure, when rotating parts fail or the motor’s insulation is faulty, involves changing the insulation or rewinding the motor. The motivation for this practice is to increase the quality and effectiveness of the motor. Additionally, the removal of dynamic unbalance from motor parts is performed to reduce vibrations and extend the motor’s lifespan.

Furthermore, lubricating such bearings with the correct grease or oil prevents knocking, early ignition, and helps increase the performance of the equipment, such as the motor. Following repairs, sequential testing is conducted to ensure that all components are functioning correctly and that the motor or equipment returns to full operation. There are specific tool composites that can also build up increased downtime and extend the total operational life of the motor.

Reference Sources

-

Mechanical Design of Electric Machines

- Key Findings: This paper focuses on the design aspects of PM (Permanent Magnet) Brushless Motors. It highlights the structural components, including the stator (laminated structure with copper coils) and rotor (shaft with integrated permanent magnets).

-

Design and Construction of a Multipole Electric Motor

- Key Findings: This study introduces a multipole electric motor with advanced digital speed and torque control systems. The design eliminates the need for mechanical couplings, improving energy efficiency and operational precision.

Frequently Asked Questions (FAQs)

Q: How can I find electric motor replacement parts?

A: Looking for spare parts for an electric motor is a straightforward thing that can be done with many different suppliers, a physical store, or an online website where there is an equally varied selection of services to find such replacements. It is also essential to identify the necessary motor parts to be purchased, depending on the requirements of the electric motor. For instance, if it requires bearings, it also involves other parts, such as coils or even a new rotor. Often, it is previous or original tools that are greatly appreciated due to their compatibility and reliability in many cases. At the same time, it is also assumed that there may still be inventory available at local motor service centers that can help narrow down the search for parts for electric motors.

Q: What is the role of the stator in electric motors?

A: The stator is one of the most critical components in electric motors, as its purpose is to create a magnetic field that makes the rotor rotate. In simple terms, it is the part that does not move along with the rotor. This is how it converts mechanical energy into motion. What is the most critical significance of the stator? The motor itself would make no sense without it. Any problem encountered in the stator would naturally cause a significant decrease in the motor’s efficiency. That would, in turn, increase electricity tariffs, prompting the need for electric motor repair. Hence, the practicality of the stator, a basic device for generating electric energy, is necessary, especially when it comes to maintaining electric motors used in many HVAC systems.

Q: How do I perform electric motor repair on a winding?

A: The repair or inline motor troubleshooting procedures often start with winding. There are cases involving the conductor breaking or a short circuit occurring; the operator has to recognize them when the windings are open. Start by disconnecting and ensuring the motor is safe to dismantle from the power sources. Investigate the various lines; if they appear worn or if portions appear damaged on the winding. In such a case, a winding kit can help repair the damaged portions of the windings. It is crucial when repairing practical motors to ensure the exact repair configurations or locations are identified, so that the motors can be functional again. Hence, if in doubt, repairs should not be made, and a specialist should be consulted in the case of a critical motor issue.

Q: What are some common problems with bearings in electric motors?

A: There are some complex underlying challenges facing the electric motors’ bearings in our daily operations. These include corrosion, which is the most common and is assumed to be the first. This, in total, creates high resistance in the bearing and heating system, which will, in turn, lead to the motor’s stoppage. The life of the bearings can be extended through routine checks, including monitoring the motor sound and oil balance. In case of bearing wear, wear it off. It should not continue to operate until it goes bad and should be replaced with OEM or other high-quality motor parts. Struggling with the well-known bearing problems, which are difficult to ignore, will increase the frequency of stoppages and the cost of repairs, considering that such procedures would likely need to be repeated.