The cornerstone of the modern industrial and technological world is the Static Frequency Converters (SFCs). These convert and transfer electrical power effectively from one frequency to another by means of a sophisticated and a very precise solution. They are the majorly used devices that adapt the power standards of one area to the world or the other and hence are very indispensable in providing the compatibility and efficiency of power supply. The role played by these devices makes it necessary that a breakdown be provided of how they operate, the basics of frequency conversion, and the large-scale industrial relevance. It is said that the best way to appreciate the importance of SFCs is by understanding the components and processes of the device, which will result in the optimization of its performance in all the varied applications that it is intended for. Let us break down the intricate working of this critical device and its industry application just right for you and me.

Introduction to Static Frequency Converters

The machines that can change the frequency of the electricity in more than one dimension (alternative to static frequency converters or SFCs) won’t let the current go but their job is to take direct current (AC), into a conversion that uses rectification for the very beginning, and then, a new use of inverter power for bringing the A/C back at the required frequency. The result will be a future with perfect control of motor speeds and synchronizing the equipment with the motor in such a way that the operations move as one, also, the possibility of operating different power systems at various frequencies or not being bound to a specific power system at all. Some of the areas where SFCs are in use include the aerospace, manufacturing and energy sectors, where they are the ones who make the systems energy-efficient and flexible when it comes to power supply needs.

What is a Static Frequency Converter?

A Static Frequency Converter (SFC) is an innovation in the world of electronics that uses high-speed semiconductors to power shift from one frequency to another without the requirement of any mechanical conversion. The process involves the transformation of the incoming alternating current (AC) to direct current (DC) through rectification of the alternating current, change of the DC, and finally, at the end of the process, the alteration of the DC to AC, and the required output frequency. SFCs play a very important role in sectors where highly accurate frequency control is essential, such as situations where equipment is built for one frequency and needs to be connected to a power grid with a different frequency, or power generation systems, where SFCs help in the case of high-turning-speed electric motors.

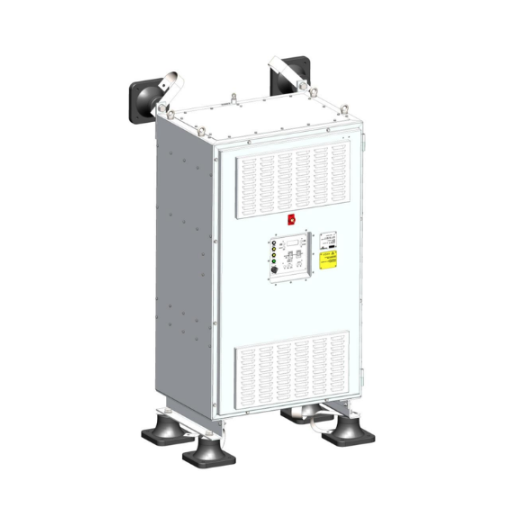

The latest SFCs are kitted out with high-level digital controllers, leading to advantages like better performance, reliability, and operational options. These types of converters are super effective, highly reliable, and most of the time also connected to the diagnostic and monitoring systems that track the performance to ensure smooth systems. They are vital for the aero sector, helping in the grounding of the planes by giving the power through ground power units (GPUs), in factories, for example, monument processing, turning, and milling machines, and in the renewable energy sector when it comes to stabilizing the power to comply with grid requirements. They are versatile as well as reliable and, as such, are a must-have technology for the industries that need to convert power with pinpoint accuracy and get the maximum efficiency.

Basic Principles of Frequency Conversion

Frequency conversion encompasses the very foundation of converting the frequency of an electrical signal to achieve the desired targets, generally with the use of power electronics. A signal is given as input in the shape of AC, and we perform rectification by a rectifier circuit till we get DC out of it. The same DC signal is then inverted into an AC signal with the frequency level at the point of desire through an inverter stage, which is mostly controlled by the modulated switching techniques of Pulse Width Modulation (PWM).

Nowadays, frequency converters are predominantly based on insulated-gate bipolar transistors (IGBTs) and similar high-end semiconductor devices that provide better efficiency and accuracy. The frequency and voltage of the output can be precisely adjusted to be suitable for different applications and this also guarantees compatibility with new electrical systems. A good example would be the use of frequency converters along with motors where the speed and torque of the motor are being determined by the power frequency changes, thus gaining the advantages of the energy and mechanical performance optimization.

The enhancement in reliability and accuracy of the frequency converters has been significantly impacted by very recent progress in digital signal processing (DSP) and control algorithms. Not only that, but adding predictive maintenance capabilities and real-time monitoring systems introduces the possibility of preemptive actions, which would, in turn, cause downtime to be minimized and operational stability to be enhanced. The essential points of this statement are the crucial part that frequency conversion plays in the industrial, aerospace, and renewable energy applications of this century.

Importance of Reliable Power Systems

Dependable power systems are crucial for sustaining critical infrastructure operations and the operation of factories, medical centers, data centers, and telecommunication systems forever. The growing utilization of renewable energy, such as wind and solar, has caused a higher need for very advanced power management techniques to help in the stabilization of the unpredictable inputs. The power sector has the core pillars of energy storage, automation, and control which have the capacity to provide the mains for a continuous supply of clean, and then, and stable power. The findings from several studies show that power cuts and their fluctuations can result in a loss of a very large amount in the economy. Hence, the monetary amount they take annually, as high as billions of dollars, is evidence of the importance of having very strong and resistant power networks. Additionally, practices like local grids and the generation of energy near the consumers have improved the flexibility of the power system, and thus, they make sure the system acts as if it is a large power source for the growing global population, alongside the dense and high-tech energy technology evolution.

Essential Components of Static Frequency Converters

Static frequency converters (SFCs) are composed of intricate systems, the purpose of which is to convert electric power from one frequency to another. The most important elements are:

- Rectifier Unit: The main duty is converting AC power into DC; this is done by means of controlled or uncontrolled rectifiers, mostly. And this phase is responsible for ensuring the DC power supply flow is constant.

- DC Link: Acts as an intermediate stage that stabilizes and stores DC power. It may include components like capacitors or inductors to filter and regulate the energy flow.

- Inverter Unit: To make the already-stabilized DC power to be converted back to AC at the desired frequency and voltage. Through the advanced inverters, it is possible to control the output waveform with great accuracy.

- Control System: This is the part that is responsible for watching and managing the converter’s operation, making it synchronized, preventing inefficient energy transfer and the deactivation because of faults. One of the common ways of doing it is using digital signal processors for the precise control of a conduct.

- Cooling Mechanism: The mechanism stabilizes the operating temperatures of the components of the system by either air or liquid cooling systems most of the time to prevent overheating, and ensure the system is reliable.

It is the conjunction of these factors that gives static frequency converters their strength and effectiveness, which in turn makes them able to be used in various applications such as frequency control, system drives, and storage.

The Role of the Rectifier

The rectifier, being part of static frequency converters, is the most vulnerable because it is the one that is responsible for converting alternating current (AC) into direct current (DC). This process is known as rectification, which is typically high voltage, or thyristor-based rectifier circuits. It merely depends on the particular application and operational requirements. However, today’s rectifiers are more efficient than the traditional ones because they allow for low power losses and give output DC that is not only stable but also provides a good foundation for the following inverter stage.

Whenever designing advanced rectifiers, they are mostly embedded with power factor correction (PFC) to extend and enhance the efficiency of reducing the reactive power. Moreover, rectifiers that contain 6-pulse or 12-pulse designs are preferred to operate them. This not only reduces the harmonic distortion but it also helps in meeting the power quality regulations set by the industry. The above features, combined with the 6-pulse and 12-pulse configurations, provide a versatile power supply system, which has the capability of working with the proper frequency and the voltage settings of subsequent stages.

Understanding the DC Link

The DC link has now become a major part of power conversion systems in modern cities, and it is no longer possible to administer the connection without its role as an essential part of the AC-to-DC rectification stage and the DC-to-AC inversion stage. Its main role is to stabilize and store energy in the form of a fixed DC voltage which is a prerequisite for maintaining continuous power flow and precise voltage regulation in downstream applications. The DC link is most commonly made up of a single or a group of capacitors that are designed for the purpose of smoothing out the voltage ripple and transient disturbance, thereby guaranteeing a consistent quality of output.

Advanced DC link implementations can also have additional characteristics like active damping mechanisms and voltage balancing systems, which make them capable of handling high-power demands and still being operationally efficient. Electrolytic and Film capacitors with high energy densities are the most often used ones; these are chosen as they are capable of suffering a decrease in voltage, and at the same time, their service-life is long. Also, they can be exposed to current ripples and still, they will not be overheated. At the same time, they are picked up based on all the performance characteristics such as ripple current handling and thermal stability to cater to the demands imposed by industrial applications. The DC link performs the job of a storage device and energy reserve, and thus, it aids in lessening the impact of the load fluctuations on the total power conversion process.

Functionality of the Inverter

The main role of the inverter is to convert the direct current (DC) into alternating current (AC) to meet the needs of both modern electrical appliances and the grid systems. The use of the best pulse-width modulation (PWM) techniques available makes inverters have the best control (and resulting high quality power) with the lowest harmonic distortion rate. It is so needed, especially in applications where power quality is very important, like in the medical field, data centers, and new and renewable energy systems.

Moreover, the new and so-called modern inverters are also featured with highly developed monitoring and control systems which aim at increasing the efficiency and reliability of the whole system. Functions like maximum power point tracking (MPPT) and the extremely high-performing photovoltaic (PV) systems are another advantage to productivity since the output is being altered to the constant conditions (environment) indeed. Whereby, the inverters’ toughness and the operational stability are further guaranteed through the temperature control systems and also the overvoltage protection mechanisms.

The efficiency of industrial and renewable energy application inverters is often more than 98% and one of the major causes of this development is the use of silicon carbide (SiC) or gallium nitride (GaN) semiconductor components. These semiconductors provide the potential to have higher switching frequencies, lower thermal losses, and more compact inverters. As a result, inverters have already become the go-to solution for many applications operating with different setups, consequently, speeding up the ongoing evolution into larger sustainable and efficient energy systems.

Operational Process of Static Frequency Converters

The static frequency converters (SFCs) have the capability of changing the electrical power’s frequency, hence frequency variance. They are very much used in applications where the frequency varies. It all starts at the rectifier stage, in which the AC input power gets transformed into DC with the help of a diode or a controlled rectifier. Next, the inverter phase takes place, and the DC is again converted to AC with the desired output frequency. The latest control methods find their usage in the process, ensuring the smooth regulation of the DC–AC transition, and, hence, minimal losses and high power quality. Renewable energy, industrial drives, and aviation are the sectors in which SFCs are most used and people can see one being a bridge for the exceptional increase in green energy.

Step-by-Step Breakdown of Operation

- Input Power Stage

The Static Frequency Converter (SFC) operation starts with the input power part of the assembly. In this part, converters get alternating current (AC) from the main power lines or other sources of power. The input of the current can be different in frequency and voltage according to the application. - Rectification Process

During this time, the incoming AC power is transformed into direct current (DC) through high-quality diodes or controlled rectifiers such as thyristors. The rectification process has to be very accurate to reduce harmonic distortion and simultaneously raise the system’s total efficiency. Moreover, the advanced rectifiers mostly come with filters for the suppression of the ripple and consequent assurance of a smooth DC output. - DC Link Stage

What happens next is that the DC power which has been rectified is sent into an intermediate DC link that happens to be another critical component created to keep voltage levels stable. At this stage, capacitors and inductors have been utilized to fulfill the purpose of storing energy and balancing out the rapid changes in voltage, thus, giving out a reliable and constant DC source. Here, this stage of buffering is also the one to ensure that the power flow is uninterrupted to the next phase. - Conversion to Output AC

Then, electricity is transformed back from the stabilized DC form to the AC form with the help of an inverter, producing the desired output frequency and voltage. For the conversion of AC power back to the inverter, fast-switching devices such as Insulated-Gate Bipolar Transistors or insulated-gate bipolar transistors (IGBTs) are used. The accuracy in this conversion stage is very important to bring the inverter output in line with the target application requirements, be it a change in voltage level, frequency, or waveform. - Output Filtering and Regulation

To make sure that power quality remains high, the inverter output has to pass through advanced filtering systems. These filters will get rid of all left-over harmonics or noise and thus, a pure sinusoidal AC output will be achieved. Furthermore, the system design includes the control algorithms that can dynamically adjust the inverter operation to cope with load changes and variations in the environment, thus increasing the total system reliability considerably. - System Monitoring and Control

The latest SFCs come with sophisticated monitoring systems furnished with sensors and microprocessors. These systems are in charge of constantly checking operational parameters, including but not limited to voltage, current, and temperature. The instant availability of data has made it possible to improve the system’s performance, identify problems in advance, and operate power conversion operations more economically.

How Electrical Power is Converted

The conversion of electrical power into other forms of energy and finally into the specific form required for various systems and applications is part of the essence of electrical power conversion. For this purpose, the devices are used, typically, which are rectifiers, inverters, transformers and converters based on the basic principles of physics and electrical engineering.

- AC to DC Conversion

The most common way of converting alternating current (AC) to direct current (DC) is through rectification. The rectifiers that could be half-wave, full-wave, or bridge types facilitate the flow of current in only one direction by using diodes. This is very crucial in the applications like charging batteries or providing DC-operated devices with a stable power source. - DC to AC Conversion

Inverters are the ones that convert DC to AC through a process. The new inverters use pulse-width modulation (PWM) for generating a standard AC wave that is a constant angular frequency with the correct amplitude, high efficiency, and nearly zero power loss. These power electronic converters are of utmost importance in renewable energy systems like solar panels, which produce a type of electrical power that is supposed to be transformed to an AC one for grid compatibility. - Voltage Level Transformation

Transformers are devices that either boost or buck voltage levels as per system needs. The operation involves electromagnetic induction, wherein the alternating current in the primary coil provokes an equivalent current in the secondary coil as per the turns ratio. Voltage transformation is widely applied in power transmission and distribution grids. - Power Factor Correction

A lot of the conversion systems that you will come across have power factor correction (PFC) circuits in them to make electric power more effectively utilized. PFC has the job of reducing the phase shift between voltage and current to minimum values that result in power losses reduction and power conversion process efficiency improvement. - Energy Efficiency Optimization

Control algorithms and real-time monitoring methods that are top-notch are making their way into power supplies via integration more than ever nowadays. The said innovations are destined to make the most of energy, but they also come with the added benefit of being able to handle very variable loads and thus incorporate safety mechanisms in case of failure, making the system very strong and safe against failures.

Any given power conversion process’s every single step right from the beginning is done in such a way that for its efficiency, reliability, and adaptability are the watchwords, and consequently the result is the smoothest-ever integration of that process into the state-of-the-art energy infrastructure.

Applications of Static Frequency Converters

The employment of static frequency converters (SFCs) is widespread in numerous sectors due to their significant role in efficiently transforming the incoming electrical frequency to suit the needs of the particular industry. Typical uses are represented by those mentioned below:

- Aerospace and Aviation: The SFCs are utilized in the ground power units that provide the 400 Hz power to the aircraft during maintenance or preflight operations.

- Marine Industry: Shipboard power systems can be easily connected to the shore power frequencies with the support of SFCs; hence, the maritime industry can have international port compatibility.

- Manufacturing and Industrial Processes: SFCs will offer the needed frequency control for precision machinery and tools that require consistent power quality, and this will be of great benefit to the manufacturing processes worldwide.

- Rail Systems: They ensure that the frequency for railway electrification systems is correct, and this activity allows the trains to move smoothly without any delays.

- Renewable Energy Systems: The SFCs make the energy transmission and grid integration possible by adjusting the frequencies of the output lines to grid standards.

In guaranteeing operational efficiency and compatibility in different sectors, the applications of static frequency converters are being featured as highly versatile and indispensable.

Use in Aerospace and Aviation

In aerospace and aviation, static frequency converters (SFCs) stand as one of the critical players, fulfilling the special power demands of the two sectors. Normally, aircraft systems are subjected to 400 Hz, which is quite apart from the 50 Hz or 60 Hz that you see in the majority of electrical grids. SFCs are the guarantee that a fault-tolerant and accurately matched frequency conversion will be provided to meet this need. Hence, the groundwork and the onboard systems will be compatible and it will not be necessary for the engine to be operated actively during the maintenance or pre-flight study phases, thus, reducing the fuel consumption and the emissions while at the same time increasing efficiency.

Ground power units (GPUs) very often bear a reliance on SFCs, let alone the airports. As a matter of fact, the GPUs will provide electricity to the parked aircraft at terminals with the help of these converters. Even while docked, the operation of the aircraft is safely permitted with the help of the converters for systems like avionics, cabin lighting, and air conditioning. Moreover, the progressive developments in the SFC technology sector have considerably increased their energy effectivity, reduced the heat they emit, and raised reliability thus going along with the aviation industry’s green move. The privileges ultimately mark the invaluable role of SFCs in ensuring business-as-usual and eco-friendliness with minimum impact on the environment in the aerospace and aviation sectors.

Impact on Manufacturing Processes

The application of SFC technology has been a major revolution in the aerospace sector manufacturing methods as it has enabled high precision, efficiency, and scalability. The use of state-of-the-art technology, such as the computer-controlled SFCs, facilitates work without any breaks and completely adaptive production requirements. It has also been a progress in the lean manufacturing field because with SFC technologies, the material waste and production delays are greatly minimized. Moreover, the shift to the application of predictive analytics and IoT technologies in modern SFCs makes it possible for manufacturers to be in control of the real-time performance data, preempt maintenance schedules, and at the same time lessen unanticipated machine downtimes.

Not only do these technologies make overall throughput better but they also make it easier for the manufacturers to comply with the strict industry standards of quality and safety. The durability of SFC units is further enhanced by the modular designs, which additionally facilitate and speed up the assembly procedures, thus making cost-effective upgrades and future refer to the scaling of operations, without the integrity of operations being affected. With the combined effect and result of these advancements, SFC-based manufacturing, therefore, looms large in the picture of the overall aerospace supply chain and becomes one of the main transporters of higher efficiency and sustainability across the entire industry.

Role in Renewable Energy Systems

SFC methodologies are one of the key factors that contribute to the performance optimization of renewable energy autonomy by advancing process control and automation alongside it. One more SFC has resulted in Wind energy subsystems having more reliable applications as they make the control process run strictly on a sequence based on blade pitch settings and power regulation based on the wind speeds. In addition to that, Solar power plants have achieved the same benefits by using SFCs to control the energy source to the maximum capacity, thus ensuring real-time response to environmental changes and, consequently, better utilization of energy at all times.

The use of storage-flow-computing-driven grid systems offers an efficient way to smooth out the variable nature of renewable energy sources. Just as examples, by now, both lithium-ion and solid-state batteries have been the main beneficiaries of SFC-based algorithms that help to achieve the maximum number of charge and discharge cycles and thus to avoid power losses. In addition to that, by the utilization of SFCs in smart grids, the control points are tightened and demand-side management is easier, hence energy consumption is made more predictable and closer to the supply, which reduces the wastage and improves grid stability.

This way, not only does the function of a renewable energy system become smoother, but also the overall impact of the energy sector on the environment is significantly reduced, which means further away from substances that produce harmful gases and a lowering of carbon dioxide releases to the atmosphere. Using the facilities of the technologies, the SFCs not only perfectly integrate but they are also the best choice for tool provision for the transition to cleaner energy that we are already undergoing.

Comparative Analysis: Static vs. Rotary Frequency Converters

Static Frequency Converters (SFCs) are devices that convert power frequencies using only solid-state devices and thus, have very high efficiency, very low maintenance, and very small designs. They are most suited to applications where the frequency has to be precisely controlled and where the noise of the operation should be kept at a minimum.

Rotary Frequency Converters (RFCs), on the other hand, are basically two machines, a motor and a generator, that are combined to achieve frequency conversion through mechanical means. Despite the fact that they are larger and require more frequent maintenance, they work very well in environments with high load fluctuations and they are also very robust under tough conditions.

Choosing between SFCs and RFCs is a matter of the specific application requirements. SFCs are the right choice for present-day, energy-saving and space-efficient systems where the top requirement is being reliable, while RFCs will be the winners in situations where continuous durability under changing load conditions is a must.

Compare Static Frequency Converters and Rotary Frequency Converters

| Feature | Static Frequency Converter | Rotary Frequency Converter |

|---|---|---|

| Technology | Solid-state, no moving parts | Electromechanical uses rotating machines |

| Efficiency | High, minimal energy loss | Moderate, higher energy consumption |

| Maintenance Requirements | Low, fewer components to service | High, mechanical parts need upkeep |

| Size and Weight | Compact and lightweight | Large and heavy |

| Noise Levels | Silent operation | Noticeable mechanical noise |

| Energy Efficiency | Very energy-efficient | Less efficient in energy usage |

| Durability Under Load | Sensitive to sudden load variations | Highly durable with fluctuating loads |

| Installation Complexity | Simple, plug-and-play | More complex, requires skilled labor |

| Operational Lifespan | Long due to no moving parts | Shorter, wear on mechanical components |

| Cost | Higher initial cost | Lower initial cost |

| Suitability for Modern Systems | Ideal for energy-efficient setups | Compatible with traditional infrastructure |

| Scalability | Better scalability | Limited scalability |

| Precision in Frequency Output | Highly precise | Less precise |

| Environmental Conditions Tolerance | Low, sensitive to extreme conditions | High, rugged operation |

| Applications | Data centers, renewable energy systems | Industrial plants, legacy systems |

Reliability and Maintenance Considerations

When discussing reliability and maintenance, it is essential to closely scrutinize system uptime, required service intervals, and the overall operational lifespan. Reliability in the case of contemporary systems is frequently achieved by a combination of inherent redundancies and sophisticated monitoring technologies. The latter grants the operators the advantage of employing predictive maintenance as the system is online. This involves the use of sensors and, through algorithms and data evaluation, the detection of failures that are likely to happen in the future, which results in a considerable amount of saved downtime.

In contrast, conventional configurations might count on having regular or preventive maintenance, which could more likely cause rising expenses and operational risks in the future. Moreover, the equipment for more severe environments is equipped with the toughest of the tough parts to prevent long-term breakdowns even if faced with harsh temperatures, moisture, or dust. The systems would still be optimized maintenance-wise by regular calibration, component replacement cycles, and strict adherence to the manufacturer’s recommendations.

Reference Sources

- AIP Publishing: Static frequency converter for large pumped storage units

This paper discusses high-voltage static frequency converters used in pumped storage applications. - HAL Open Science: Static frequency converter for hybrid pumped storage

This document explores the use of static frequency converters in hybrid pumped storage systems. - arXiv: A simplified static frequency converter model

This paper presents an open model for static frequency converters, particularly for electromechanical stability studies in railway grids.

Frequently Asked Questions (FAQs)

How does a static frequency converter convert electrical power for aviation and aircraft power?

A static frequency converter is a device that is capable of converting electrical power from the grid or Input AC power to AC power of any desired frequency, commonly 400Hz for aviation and aircraft power systems. Static frequency converters are built with power semiconductors and control electronics that provide accurate frequency and voltage. They are suitable for use in the onboard systems to cope with the power requirements. Even though they are the most complicated machines, they allow frequency conversion with the aid of solid-state materials, so there is no need for any moving parts, hence better maintenance-free and long-lasting.

Can a frequency converter or static converter replace a rotary frequency converter for ground support?

In certain cases, a ground support situation exists where the converter is basically efficient in terms of frequency conversion and specific power requirements, in which a rotary frequency converter could be replaced by a frequency converter. Because of their ability to vary frequency and quick response, static frequency converters are the most efficient ones. They are a perfect choice for applications that require variable power and higher power systems and can be obtained as units with different power capacities and different output power ratings. The static converter employs power semiconductors and control algorithms similar to the ones utilized in the variable frequency drive technology to control input frequency and generate the required different output frequencies.

How does a static frequency converter handle input AC power, voltage, and frequency conversion?

A static frequency converter simply converts the power we get from the grid into mid-frequency electricity, and then does an inversion of this to finally get the same grid power at the desired frequency and voltage, satisfying the requirements of both the voltage and the frequency. Such a two-step technology makes it conceivable to control the frequency and amplitude extremely accurately, as well as to have the flexibility in frequency and voltage control across different output frequency characteristics. Using power semiconductors to drive the inverter rectifier, the converter is designed to suit the power requirement exactly and, at the same time, control the noise and the quality of the power that is being delivered.

Why are static frequency converters used instead of frequency changers for precise frequency and power needs?

Static frequency converters are utilized due to the fact that they allow the provision of exact frequency and steady output power without being dependent on inertia and maintenance of rotary systems, thus, they can comply with the stringent frequency requirements and the needs for frequency change Besides, it is easy to make them optimum for frequency conversion that is very efficient, and they can become application power compatible and output power profile specific by customizing them with the criteria that you need The state-of-art design enables quick changes in frequency and amplitude that are desirable for adjustable frequency testing and simulation.