The accuracy of the power system is the process that defines the compatibility, performance, and efficiency of power grids and electronic devices worldwide. 50Hz and 60Hz are the two most commonly used frequency standards. The difference between them is not only in the numerical value; it also affects the design of infrastructure, the amount of energy transmitted, and the operation of many devices. This post is intended to address the rumors about 50Hz and 60Hz power systems from a technical perspective. Therefore, in this post, we will look at the historical background, the practical side, and how the two different frequencies affect global industries. In the end, you will know so much more about how the very heart of the power system can determine the cost of energy production and the neighborhood of wonder when the tiniest kitchen gadget is in question.

What is Frequency?

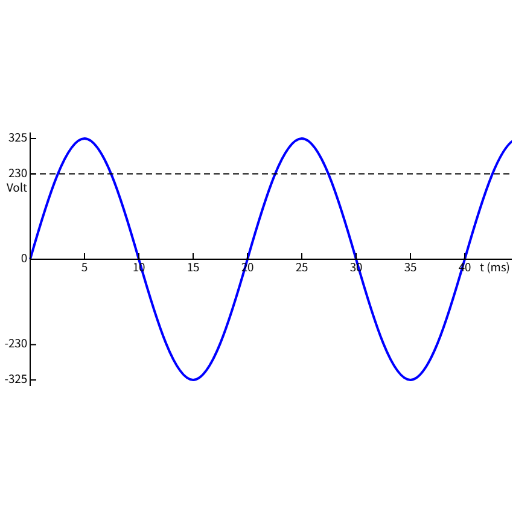

Frequency, in its simplest form, is the number of vibrations or movements that a wave makes in one second. It is measured in hertz (Hz), where 1 Hz equals one cycle per second. In power systems, frequency is the speed at which alternating current (AC) reverses direction. For instance, a 50 Hz system accomplishes 50 cycles per second, while a 60 Hz system accomplishes 60 cycles per second. Frequency, among other things, is the most essential subject to be addressed in the power and equipment industry, where it is directly linked to the operation of machines and the like, as well as to power grid synchronization in time and frequency.

Definition of Hertz and Frequency

For the optimization and analysis of contemporary electric and electronic systems, it is essential to understand the meanings of hertz and frequency. One of the things that frequency does well is ensure power grid consistency, which allows the wide range of devices that depend on AC operation to operate smoothly. For example, variations in the standard frequencies of 50Hz or 60Hz can cause a range of issues, from equipment malfunctions to inefficiency and damage to sensitive components like motors or transformers. Thanks to technological developments, grid operators can benefit from real-time frequency monitoring, which helps them maintain system stability quickly and easily. Moreover, the increasing share of renewable energy sources like wind and solar power has made it increasingly difficult to maintain grid frequency stability, so in this situation, one has to develop innovative products such as dynamic inverters and grid-scale battery systems. It implies that frequency control is the most crucial measure across the entire energy system chain to ensure reliable and efficient operations.

Importance of Frequency in Electrical Systems

It is essential to maintain a stable frequency in electrical systems, as slight variations can significantly affect the performance and reliability of the grid. If the grid frequency differs from its nominal value —usually 50 Hz or 60 Hz, depending on the region —this can lead to waste, equipment malfunctions, or, in extreme cases, power outages in a large area. Generators may burn out from overload and a lack of synchronous movement, while in the case of high-frequency deviations, the turbines may be damaged due to excessive speed.

In the present era, power systems operate by closely monitoring the frequency of the power supply, which is supplied by different forms of energy, mainly non-stop production sources like wind and solar. The quality of frequency regulation is so good that the automatically operated system facilitates transitions among energy sources with minimal risk of grid collapse. Extensions of the stand-alone frequency regulation systems, such as the Frequency Measurement Units and highly nonlinear surface surveillance, enable operators to search for and address disturbances with a never-before-achieved level of accuracy, while also strengthening grid resilience.

Overview of 50Hz and 60Hz

The electrical power supply in the world is, in general, regulated in terms of its frequency to 50Hz or 60Hz at the choice of the strongest authority in the area or territory assigned to it. The 50 Hz system is prevalent in Europe, most of Asia, Africa, and Australia, while the 60 Hz system is standard in North America, some regions of South America, and a few other places in Asia.

The frequency of the electricity grid affects many engineering parameters. These include specifications for generators and transformers, transmission efficiency, and the compatibility of end-use equipment. Let me give you an example. In a 60 Hz system, the need for transformers and equipment that can operate at higher speeds is reduced, resulting in slightly better performance for specific uses only. On the other hand, 50 Hz systems, forced to lower frequency, have been widely regarded as more suitable for power transmission over long distances under certain conditions due to reduced reactive power losses.

More and more devices are now made to work without any problem at both frequencies, due to globalization and trans-regional trade. Nevertheless, it is not easy to cross-connect grids operating at different frequencies, because the phases are not in synchrony and the frequencies are not the same, and this can only be addressed by using high-voltage direct current (HVDC) links or sophisticated static converter systems. These transformations still facilitate the incorporation of independent grids into larger, more adaptable energy networks, thereby globally securing energy and sharing other resources.

Technical Differences Between 50Hz and 60Hz

- Efficiency and Power Loss: 60Hz devices are typically a bit more efficient and have lower power loss than 50Hz models. The reason is that higher frequencies reduce the core losses of transformers and other inductive equipment.

- Equipment Design: The motors and transformers need to be specifically designed for the operating frequency. When a motor is manufactured with a 50Hz frequency, it will run faster if connected to a 60Hz power source and thus it brings about overheating and other operational issues, a 60Hz motor at 50Hz may totally shut down for it will either underperform or overheat.

- Transmission Considerations: Due to the higher magnetic flux, systems tailored for 50Hz invariably require larger equipment, such as transformers and electric generators. This would increase the measurement and the cost of the system compared to a 60Hz system.

- Regional Standardization: Most of Europe, Asia, and Africa use 50Hz as the standard frequency, while 60Hz is mainly found in North America and parts of South America. This incongruity in grid connections worldwide necessitates frequency-conversion technologies for interoperability.

Compare Differences Between 50Hz and 60Hz

| Parameter | 50Hz | 60Hz |

|---|---|---|

| Frequency (Hz) | 50 | 60 |

| Regions of Use | Europe, Asia, Africa | North and South America |

| Magnetic Flux | Higher; increases size of transformers | Lower; reduces size of transformers |

| Energy Losses | Slightly higher due to lower frequency | Slightly lower due to higher frequency |

| Efficiency (Machines) | Less efficient with smaller equipment | More efficient for smaller equipment |

| Grid Interconnection | Complex with 60Hz regions | Complex with 50Hz regions |

| Transmission Losses | Marginally higher | Marginally lower |

| Motor Speed | Operates at lower revolutions | Operates at higher revolutions |

| Cost Implications | Equipment is generally larger and costlier | Smaller, less expensive equipment |

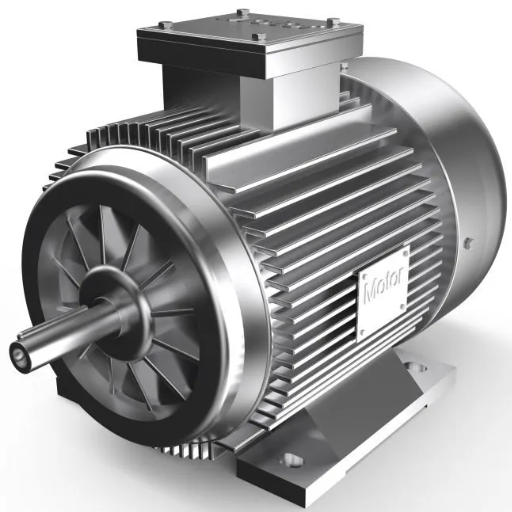

Impact on Electrical Devices and Motors

The difference between 50Hz and 60Hz power systems significantly affects the design, performance, and efficiency of electrical devices and motors. Motors made for 60Hz typically run at higher rotational speeds than their 50Hz equivalents because of the direct proportionality between frequency and synchronous speed. For example, a 4-pole motor operating at 60Hz will run at approximately 1800 RPM, which is approximately 300 RPM more than the 50Hz motor, which runs at 1500 RPM. When these different speeds matter, motors are a crucial part of the application, as in industrial machinery, pumps, and fans.

Moreover, the rate of output impacts, first, supply prices and electricity consumption. The equipment, adjusted to a working frequency of 50Hz, shall have windings with larger cores to meet the frequency requirements, leading to larger size requirements and hence more materials. However, using the 60Hz frequency to some extent results in more compact designs, which in turn lead to lower production costs and smaller computers that use less energy. An article on a website discussed the factors of a particular device, and 50Hz motors were the subject. Even if the situation, cost, delivery time, and the like are more significant, the 50Hz motor is often regarded as rugged; in this case, that is, the application.

Another field of influence is the availability of compatible connections to worldwide systems. The majority of devices operating within a specific frequency environment are likely to experience high temperatures and reduced efficiency, with possible mechanical defects, when powered by unsuitable sources without appropriate changes or frequency converters. Conclusively, for the global market, they must be fully designed in accordance with the country-specific technical and regulatory requirements, one of which is the frequency for electrical equipment.

Voltage Variances in 50Hz vs 60Hz Systems

Standards for electric power also differ significantly in volts depending on the locality, whether it is a 50 Hz or a 60 Hz system. In places where 50 Hz power is used, it is common for the power to be introduced at 220-240V, although the 60 Hz one is among the 111-120V. The changes actually affect the plan and use of equipment and so on. The makers of equipment for higher voltages have to include, for each product, only the new insulation rating to withstand the stress of higher electrical power. Conversely, lower-voltage systems generally require higher currents for the same power output, which may result in higher energy losses in transmission and distribution unless thicker-gauge wire is used.

Another significant aspect that must not be ignored is that the frequency has a significant impact on power system sizing. Consequently, for higher frequencies, such as 60 Hz, transformers and other inductive reactance elements can be made with smaller cores due to lower magnetic saturation, which is sometimes a cost-saving strategy. On the other hand, 50Hz systems frequently require larger components for the same power levels, which may lead to higher material and manufacturing costs. Hence, these are the most essential facts, clear evidence of the connection between voltage and frequency in issues related to power system efficiency and the general principles of electrical equipment design worldwide.

Performance of Motors in Different Frequencies

It is a fact that the frequency of the electrical supply influences the motor performance. What happens if the frequency is high, such as 60Hz? This will most likely let motors run even faster due to the direct proportion between frequency and synchronous speed. However, fixed-power motors can exhibit higher core losses and reduced efficiency. On the other hand, at lower frequencies, such as 50Hz, slower motor speeds are to be expected. Still, such losses as iron and copper might be reduced, leading to lower losses, lower windings, and higher overall efficiency. Even variable torque, besides specific applications, may also be a special benefit. The motors should be designed so that operation occurs at the desired frequency to avoid overheating, vibrations, or reduced lifetime. The alignment between the motor design and the frequency should be appropriately established, which will improve both efficiency and reliability.

Motor Speed and Efficiency

The speed of a motor is a key factor that is directly proportional to its efficiency, power output, and performance across a range of uses. High-speed-rated motors supply more power, but at the expense of higher losses, as winding and friction take their toll, making it a less power-efficient unit. On the contrary, when the motor is run at lower speeds, efficiency can be enhanced, as in applications that require the highest level of precision and high torque. At the same time, if the motor is run at lower speeds, it may mean that more copper losses result from the longer time the current spends flowing through the windings.

Recent technological developments have brought about notable advancements in the optimization of motor speed controllers, including variable-frequency drives (VFDs) that automatically adjust speed to match load demand. Research findings indicate that energy savings of 30%-50% can be achieved by applying VFDs in variable-load areas, such as HVAC systems and industrial machinery. Moreover, motor selection characteristics, such as those of permanent magnet synchronous motors (PMSMs), have a significant impact on overall efficiency over long speed ranges because the motors themselves are resilient at low rotational speeds and provide uniform output.

One must have a basic understanding of the interplay between speed, load, and energy losses when designing motors with application-specific requirements. A properly matched and tuned speed control system, along with efficient motor designs, can contribute in considerable measure to savings in life-cycle costs, reduced environmental impacts, and higher operational reliability under changing circumstances.

Compatibility of Motors with 50Hz and 60Hz

The design and operational nature of the electric motor will be significantly influenced by the power supply frequency, which should be either 50Hz or 60Hz. Typically, motors are designed to operate at either frequency, but dual-frequency motors have become increasingly popular lately due to international business operations and regulations. The main difference is in the motor’s synchronous speed, which is determined by the ratio of the supply frequency to the number of poles. For instance, a motor with four poles will have synchronous speeds of 1500 RPM and 1800 RPM at 50Hz and 60Hz, respectively, in the order mentioned.

When a motor is not operated at the correct frequency, it can cause many issues. When the frequency is increased to 60Hz, the motor will run faster, which would increase mechanical stresses on bearings, rotors, and other essential components. On the other hand, running a 60Hz motor at 50Hz may slow it down, and, as a result, overheating may occur due to increased current draw if the voltage is not balanced accordingly. This is usually shown by the voltage-to-frequency ratio (V/f), which must be kept nearly constant to keep the motor running efficiently.

The development of Variable Frequency Drives (VFDs) is making it easier to adjust frequency, acceleration, and deceleration control, which can be done not only swiftly but also precisely under varying loads, without affecting performance. To make the best of all the above issues, the motor drop must be appropriately managed; that is, the thermal and mechanical limits must be considered. For areas like different countries with varieties of motor applications, using motors that are as per the standards like IEC 60034 or NEMA for old-time industry motors (electric motors) that allow the operation at two different frequencies can be a good way to go, as it will make the motor working environments similar, the efficiency losses will be minimal and machine life will be extended as well.

Frequency Converters and Transformers

Frequency converters and transformers are the hardest soldiers of the power war. Frequency converters act as power supply frequency changers, making them suitable for equipment that operates at other-than-main-frequency input (e.g., from 50 Hz to 60 Hz). This function is essential in cases like working in a different country, the military, and factories that are part of a global supply chain, where electrical power standards differ.

Transformers, in this case, are responsible for adjusting the voltage while keeping the frequency unchanged. They are a must-have tool for safely transmitting electricity over long distances and converting the voltage to a level usable by different equipment types.

When frequency converters and transformers are used together, they ensure power is adapted to any geographical region and reduce energy losses while protecting expensive equipment from both too high and too low voltages. It is highly recommended that the systems that are to be used in frequency conversion and transformation applications have the marks of the international standards, like the IEC or IEEE; this will ensure quality, safety, and no disputes concerning the power ratings and quality of service.

Understanding Frequency Converters

Frequency converters are very complex pieces of equipment used to change the electrical power frequency to meet the needs of specific machinery or systems on the input. This operation is crucial for machines that operate at frequencies that differ from those of the general public utility power system in a given area, e.g., in regions with different power standards or in some industries that cater to the global market. Usually, modern frequency converters employ adjustable-speed drives (ASDs) or variable-frequency drives (VFDs), which are essential for precision and economy in controlling motor speed and efficiency.

Input and output frequency ranges, power ratings, and harmonic distortion levels are among the paramount parameters to assess, as they directly correlate with performance and energy efficiency. An example is that frequency converters are valuable for reducing wear on mechanical components in a factory, thereby prolonging equipment life, by ensuring smooth motor operation. Modern to state-of-the-art models are incorporating digital control systems, which are very important because they support Internet of Things (IoT) connectivity and remote monitoring, thereby enabling enhanced operational oversight. The bottom line is that, through the use of these technologies, energy consumption in the industry can be closely monitored at different stages, thereby enabling productivity improvements and, very importantly, eliminating connectivity problems and meeting environmental standards.

Role of Transformers in Frequency Conversion

Transformers are an essential instrument in frequency conversion. They can transfer electric power from a circuit operating at a principal frequency to one operating at a different frequency, and they also support frequency-specific applications. The primary function of a transformer is to change the voltage level—step up or step down—so it matches the downstream equipment, such as frequency converters. The transformers used in applications of this kind are designed to withstand and mitigate the harmonic distortion and thermal stress associated with alternating frequencies, thereby minimizing energy waste and system instability. The more up-to-date the times, the more efficient transformers are; they employ the most advanced insulation materials, precise magnetic core designs, and the latest cooling systems to deliver the best possible performance as working conditions change. The technology not only increases the efficiency of the conversion process but also supports compliance with stringent energy-related regulations and demands for system reliability across manufacturing, renewable energy, and HVAC systems.

Choosing Between 50Hz and 60Hz Transformers

| Key Point | 50Hz Transformers | 60Hz Transformers |

|---|---|---|

| Frequency | Operates at 50 cycles per second | Operates at 60 cycles per second |

| Efficiency | Slightly higher due to lower frequency | Slightly lower with increased frequency |

| Size and Weight | Larger and heavier | Smaller and lighter |

| Core Losses | Lower core losses due to lower frequency | Higher core losses due to higher frequency |

| Copper Losses | Slightly higher copper losses | Slightly lower copper losses |

| Voltage Regulation | Better voltage regulation at high loads | More variation under heavier loads |

| Heat Generation | Generates less heat during operations | Generates more heat during operations |

| Energy Efficiency Standards | Widely used in Europe, Asia, and Africa | Common in North and Central America |

| System Compatibility | Used in 50Hz power grids | Designed for 60Hz electrical systems |

| Applications | Industrial, maritime, and broader global use | Domestic, commercial, widespread in the U.S. |

| Economic Viability | Suits energy regulations in 50Hz regions | Efficient for markets designed for 60Hz grid |

Making Informed Decisions for Your Needs

When choosing between 50Hz and 60Hz systems, there are three primary elements to take into account:

- Geographic Location: The frequency of your power grid in the region is the primary factor in your choice. For example, 50Hz systems are mainly the norm in Europe, Asia, and Africa, while 60Hz systems are primarily found in North and Central America.

- Intended Applications: Examine the system’s primary utility. Many heavy and marine applications require equipment rated for 50Hz, whereas home and business systems in the U.S. predominantly use 60Hz due to the widespread infrastructure.

- Regulatory Compliance: Ensure the system complies with local energy efficiency regulations and laws. By undergoing this phase, users not only improve their economic conditions but also make their systems more environmentally friendly and operationally more efficient.

Thanks to the customization of these factors to your needs, it will be easier for you to select the frequency system that best aligns with your organization’s or area of operation’s requirements.

Assessing Your Power Needs

Determining your power needs requires assessing power consumption for both today and the anticipated future so that the equipment can operate at the highest level of performance and reliability. The first step is to determine the total load demand based on the power ratings of all the equipment that will run at the same time. One has to deal with continuous and peak loads, as well as future load growth or changes in operational requirements.

As a second point, the type of power to be used—alternating current (AC) or direct current (DC)—should be specified, followed by verifying that the voltage and frequency are within the machine and regional standards. It should also be considered one of the main concerns: the up-to-date terms of efficiency that higher-efficiency energy-consuming systems can already achieve. It is time to consider energy-saving measures.

Moreover, you should consider installing monitoring tools or systems to track energy usage data in real time. This is a very effective way to look at the pattern of consumption and the whole system. It will help grow the power supply without requiring a system overhaul. Highly targeted planning and identification of the electricity needs are part of the process; they become the crux of the matter and a factor in the effectiveness (in achieving increased performance and energy efficiency).

When to Use a Frequency Converter

There are places where a frequency converter is not only an accessory but a must-have, because precise regulation of motor speed and torque is required. The most significant industries that can benefit from variable-speed drives are manufacturing, HVAC, and water treatment plants. Year by year, taxis carry more people around the globe, but not in terms of passenger count. These converters perform the same way in a vehicle as the controller helps the passengers pay attention.

When they need to cope with a system in which the frequency-controlled motor is varied to align with performance requirements or environmental conditions, these devices are essential. In the case of belt conveyors, a frequency converter ensures smooth acceleration and deceleration, reducing mechanical wear and tear while minimizing the time required to maximize output. Similarly, they could be used in applications that involve pumps and fans to modulate flow rates to the desired levels, thereby relieving the system of the need to operate wastefully.

The main factor driving the use of a frequency converter in another case is the need to change the equipment that operates on a different frequency standard, i.e., between 50 and 60 Hz, to support international business with the necessary compatibility and performance optimization across regions with different electrical standards. In these cases, a frequency converter offers many advantages beyond flexibility, reduced energy costs, and longer equipment lifetime—factors that are crucial for maintaining the same level of productivity.

Reference Sources

Detection of Electroencephalography Artefacts using Low Fidelity Equipment

Key Findings: This study discusses the use of 50Hz and 60Hz notch filters to eliminate environmental electrical interference in EEG recordings. It highlights the importance of filtering for accurate signal analysis.

Model for generating simple synthetic ECG signals

Key Findings: This study discusses adding 50Hz or 60Hz powerline noise to synthetic ECG signals to simulate real-world conditions.

Frequently Asked Questions (FAQs)

What is the frequency difference between 50Hz and 60Hz?

The principal distinction lies in the frequency at which they function – 50 Hz means 50 cycles per second, and 60 Hz means 60 cycles per second. The operational difference between these two frequencies affects electrical appliances and particularly the speed of an electric motor. If a 60Hz induction motor, for example, is produced, it will be expected to run faster than a 50Hz motor — very rarely will the two motors operate at the same speed. Moreover, the distribution of 50Hz and 60Hz worldwide is such that the 50Hz world generally serves the 50Hz world, and vice versa. Until the user is using frequency converters, compatibility must be ensured through awareness of this difference.

How does a 60Hz transformer differ from a 50Hz transformer?

A transformer is designed to operate at 60 cycles per second (Hz). And the situation is the same for the 50 Hz transformer, which is manufactured to operate at 50 cycles per second. Different frequency affects the transformer impedance and its overall performance. A transformer operating at a frequency higher than its design frequency may experience even greater eddy-current losses, which in turn can be the root cause of overheating and reduced efficiency. On the other hand, when a 50 Hz transformer is connected to a 60 Hz power supply, the load connected to that transformer may not even experience power shortages, and it may even be underpowered in the worst-case scenario.

What are the advantages and disadvantages of 50Hz vs 60Hz?

The strengths of 60Hz are the engine speed and the operational reliability of some electrical tools, especially in North America. The whole wide world runs on a 50Hz power frequency, but this may be an advantage for a large-scale offense. 60 Hz has similar effects to these, among which are using electrical devices only in an appropriate country’s electrical system, etc. However, it should be noted that the choice of power frequency will affect the transformer cost and the generator design, with the overall plant efficiency affected as a result. All these factors must be taken into consideration during the debate over 50Hz versus 60Hz.

Do I need a frequency converter for 50Hz and 60Hz devices?

You would probably need a frequency converter if you are trying to power 50Hz devices from a 60Hz power line, or vice versa. The frequency converters adjust the input voltage and frequency to match the equipment’s requirements. If you opt not to use a frequency converter, you may experience motor speed mismatches and more rapid failure of your electronic components. One rather bizarre case, a 50Hz instrument with a 60Hz transformer might not get enough power. So, electricity that matches the note called out by your instruments is a game you want to win in the long run.