Electric Motors, as we know them, are the mainstay of numerous applications, from electric vehicles to other equipment and devices such as household electrical gadgets. Nevertheless, as odd as it sounds, despite its countless applications, the electric motor is still a major mystery for many. For instance, it is crucial for service engineers and even ordinary people who carry out main tasks alone, who want to repair their electric motors themselves, to be able to tell which part of the motor is almost worn out and which part has failed so that it can be replaced. Without this knowledge, one may be doing more damage than good. For this reason, this article endeavors to address such concerns by discussing some of the major components of an electric motor, including, but not limited to, the most common challenges encountered, and how one can source the relevant material required for replacement more effectively and efficiently.

Introduction to Electric Motors

In simple terms, electric motors (EM) are invariants that absorb current and generate both magnetic and electric fields, thereby producing mechanical energy. Because of this, an electric motor finds numerous applications in factories, such as running electric lawn mower motors and innumerable other appliances. An electric motor includes the following principal components: stator, rotor, windings (coupled to rotor), and bearings(seating for rotor). It is the purpose of these pieces to interconnect and invariably set the rotating part of the motor so as to propagate rotation in the main machine. Its efficiency, durability, and capability make EMs irreplaceable both at home and at work. This education about transitions and effects is vital for maintaining the equipment and for troubleshooting the problems encountered.

What is an Electric Motor?

The electric motors are the devices that transform electrical energy into mechanical energy, and they are used in a wide variety of applications across numerous industries and in domestic settings. The electric motors operate on the principle of electromagnetism, which usually involves the relationship between magnetic fields and an electric current, facilitating the circular movement in a virtuous cycle that helps in deriving the power for activities like moving small machines and heavy machines, such as in industries. With the motor development in the past, has been the accomplishment of motors that are both efficient and green, among them being brushless DC motors and some advanced technologies of AC motors, for example, switched reluctance motors and induction machines. Such achievements have been groundbreaking in the areas of renewable energy plants, electric vehicles, and automated workflow, illustrating the limiting function of the motor in promoting the sustainable advancement of human practice.

Types of Electric Motors

| Type of Motor | Description | Applications | Key Features |

|---|---|---|---|

| DC Motor | Operates on direct current electricity | Toys, tools, small appliances | Simple design, easy to control |

| Brushless DC Motor | Uses electronics instead of brushes | Drones, EVs, medical devices | High efficiency, low maintenance |

| AC Motor | Operates on alternating current electricity | Fans, pumps, large machines | Durable, scalable |

| Induction Motor | Uses electromagnetic induction for operation | HVAC systems, conveyors | Low cost, robust |

| Synchronous Motor | Rotor and stator magnetic fields synchronize | Power plants, heavy industries | Precise speed, efficient |

| Stepper Motor | Moves in fixed angular increments | 3D printers, CNC machines | High precision, precise control |

| Servo Motor | Combines motors with feedback control | Robotics, cameras, automation | High accuracy, compact size |

| Universal Motor | Operates on both AC and DC electricity | Blenders, vacuum cleaners | Versatile, high speed |

| Linear Motor | Produces linear motion directly | Maglev trains, sliding doors | High speed, smooth motion |

| Reluctance Motor | Rotates via magnetic reluctance | Industrial drives, fans | Simple, low maintenance |

Common Applications of Electric Motors

Household Appliances

Electric motors are among the most commonly fitted components in various household appliances. Classifications of home appliances that use electric motors include, among others, fridges, air conditioning units, food processors, and vacuum cleaners. The motors facilitate smooth operation in addition to troubleshooting when they provide enough power.

Industrial Machinery

Motors are also heavily utilized in processing environments, running machines such as mixers, fans, heaters, and pick-and-place machines. The great position and efficiency present in the electric motor make them the best, especially for the provision of work in production lines and large industrial houses.

Transportation

In the sphere of mobilization and transportation means, the role of electric engines is very significant. They are applied in guided vehicles like electric motors or hybrid motors, maglev trains, aerial vehicles or aerial drones, skateboards, and many other devices that do not depend on the traditional internal combustion engines, and which are pollution-free.

Automation and Robotics

Automation and robotics implementation are largely based on electric motors and primarily applied through drives, such as servo motors, which provide precise motion. In the vast majority of cases, this is paramount in industries like electronics, medicine, and cargo, where certain levels of precision and speed are the norms

Renewable Energy Systems

Renewable energy systems, such as wind and solar power, rely on electric motors, wind turbines, and solar tracking systems, among many other components. Some of the other tasks consist of helping in intelligence activities and monitoring the extraction of power from naturally occurring sources of energy.

Aerospace Engineering

The air transport industry also uses electrical motors in the form of actuators, cooling systems, and auxiliary power units (APUs). The reduced physical footprint and ability to easily and efficiently convert inputs to outputs are just a few of the numerous applications and value aspects that electrical motors offer in aviation systems.

Key Components of Electric Motor Parts

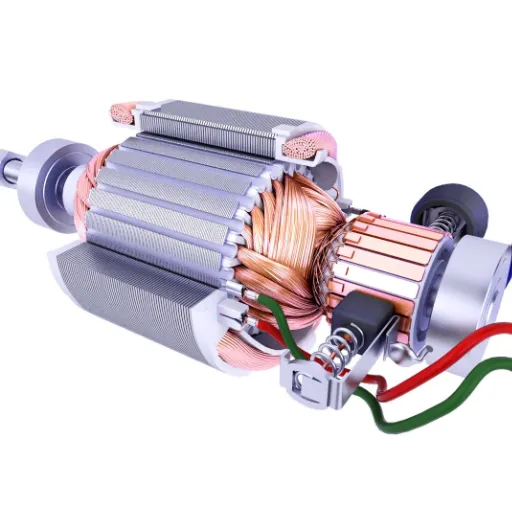

- Rotor: The mechanical energy-making part of the motor. It occupies an active place in the stator’s magnetic field to apply a rotating force.

- Stator: The stationary part of the motor, which contains windings or permanent magnets. Generates a magnetic flux to run the motor.

- Bearings: Their primary purpose is to allow the rotor to rotate efficiently while minimizing friction and wear, thereby extending its lifespan.

- Windings: Windings filled with insulated wires in the stator, which are mainly responsible for producing the field when there is an electric current flow.

- Shaft: It is the vital part of any motor that takes the mechanical power from the rotor and transmits it to the apparatus.

- Commutator or Slip Rings (in certain types of motors): In motors, they connect the electrical supply to the rotating components and provide aid for the movement of current.

Stator and Rotor Explained

An electric motor is an apparatus that converts electrical energy into mechanical energy. This transformation is completed when the stator and the rotor work in tandem to complete the motor’s operation. The stator, which is the fixed part of the electric motor, is constructed in such a way that it encloses a core with winding, the latter being in contact with the former, so as to make it generate a magnetic field when current flows through the windings. This magnetic field is directional and further helps the motor to operate as it works with the rotor, which, in turn, initiates movement of the assembly. The rotor, being the rotary element of the motor, is installed in the stator. It is arranged in such a way that it oscillates due to the action of the stator’s magnetic field. In some types of motors, for example, in induction motors, the rotor can take the form of a conductor with connections at both ends. Also, sometimes the rotor can be constructed as windings and a commutator or end rings in d.c. motors. This process of how the stator interacts with the rotor allows for the effective conversion of energy, hence underpins most achievements in electric motor technology. Use of well-selected materials in both components aids in boosting the performance, life, and, most importantly, the overall efficiency of the motor when being used.

Windings and Insulation

The windings in electric motors are vital elements for their correct and efficient operation, as they play a crucial role in creating the magnetic field. Windings are manufactured using conductive materials like copper and aluminum and are well-designed to increase effectiveness and lower power wastage. The coatings between the windings are also crucial because they assist in the protection of the generator from even short circuits and help insulate the windings to withstand thermal and electrical stresses.

Recent progress has introduced a new insulation material that provides enhanced protection against heat and exhibits improved wear resistance. With the innovations of such materials, motors can still deliver stable operations at elevated temperatures and loads. You can never go wrong with the use of polyimide film, mica composites, and special decorative insulating paints while designing an aging-friendly structure. The integration of more efficient coil configuration impulses and improved dielectric systems results in reduced energy consumption and an extended lifespan of motors. The use of the best raw materials and appropriate technology, furthermore, allows engineers to achieve optimal performance while ensuring reliability in the electrical system.

Bearings and Shaft

In any electrical motor device, the bearings and shafts are the source of any rotational movement, so they should operate as smoothly as possible. Friction arises between moving parts without them. Bearings of either the ball, roller, or sleeve type are usually selected based on specifications, such as load and speed. High-quality materials like ceramic or stainless steel are often used in the construction and design of bearings to reduce their rate of wear. Furthermore, precisely machined shafts are frequently constructed from items such as alloy steel, which adapt to the shock and vibrations from the bearings very well. This makes the high precision bearings to handle torque without d vibration installation issues effectively. The improvement in the servicing and maintenance of electric motors in a broad range of applications where they are used has also contributed to this development. The perfectly adjusted interconnection of the bearings and the shaft line is essential for reducing noise and vibrations, which would otherwise hinder the system’s functioning and reduce its service life. In the meantime, by enabling such construction, modern electric motors enable long-life operation and energy-efficient use in numerous sectors and applications within the industry.

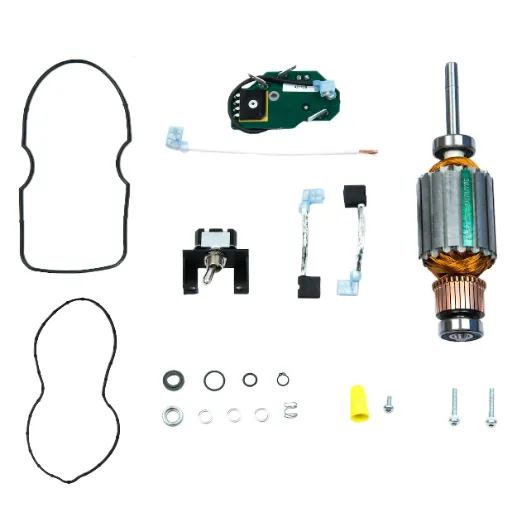

Understanding Motor Replacement Parts

The efficiency and the effective working order of electric motors can be sustained only when motor replacement parts are used. During the service life, any motor’s elements, such as bearings, brushes, seals, etc., are exposed to regular wear. Owing to these parts, the motors’ operating nature can be ensured, and there is nil chance of breakdown. The operation of the motor can be restored up to design conditions, and the motor overhaul can be postponed to a later date. The external structure requires cleaning and re-time modification for this objective, even though the aim is usually cost-effective. It is, therefore, paramount in the realization of each and every maintenance objective to always use only parts, filters, or other materials that are compatible with the motor at each stage of the maintenance plan.

Identifying When Replacement is Necessary

Knowing whether to alter engine parts is necessary to prevent any harm and maintain regular efficiency. Some of the apparent indicators are uncommon sounds for instance grindings or whining, such sounds could be areas of tear or off alignment of bearings or any other internal components. At other times, depreciation in output, such as a decrease in speed or torque, may be caused by issues with the motor windings, among other vital components. In other cases, increased overheating during runtime or the repeated switching off of the circuit breakers due to overload can be linked to electrical faults. Frequent checks are necessary as damage, such as visually observed cracks, corrosion, and excessive vibration, are some examples. Considering these factors, along with maintenance practices based on data, helps avoid costly part replacements in the short term, promoting effective use and operational efficiency.

Common Motor Replacement Parts

Bearings

The moving parts are secured by bearings and serve the purpose of reducing the frictional forces. They can also wear out eventually when subjected to too much heat or when the bearings are wrongly aligned and need to be replaced to prevent ultimately destroying the motor.

Brushes and Brush Holders

In motors that depend on brushes, these materials have a short service life because they get worn out very quickly in constant contact with the commutator. To provide the optimal level of wear, it may also be required to replace the clients with the worn-out plate.

Seals and Gaskets

The main difficulty in the sealed enclosure is that the moisture or any other cream does not get inside the motor, yet the lubricant is retained. Seals could not be damaged, and they ought to be replaced accordingly if the inflow of dirt is hindered.

Windings

The winding in the motor starts turning, and it experiences temperature increases due to heating, whereas the system of energy experiences power swelling or insulation wear, which damages the winding. Replicating or repairing the deteriorated windings helps the motor to consume power cost-effectively and avoid wasting power.

Capacitors

The function of single-phase motors is made possible by the condensers on the apparatus in both start and run modes. If the condenser fails, the greatest likelihood is that the motor will either refuse to run altogether or keep cutting out; thus, replacement of this component is a standard maintenance measure.

Rotors and Stators

In the event of excessive wear on rotors and stators, this can significantly harm the motor’s efficiency or even cause a motor system breakdown. It is advisable to replace these enhancing parts whenever necessary to extend the service life of the motor and ensure it runs effectively.

Couplings and Mounts

These parts bridge the gap between the motor and the load, and they are also responsible for absorbing the vibrations. Failed couplings or mounts can buckle, causing additional wear on other components and necessitating replacement to achieve smooth functionality.

OEM vs Aftermarket Parts Comparison

| Parameter | OEM Parts | Aftermarket Parts |

|---|---|---|

| Definition | Made by the original manufacturer | Made by third-party companies |

| Quality | Matches original specifications | It can vary depending on the manufacturer |

| Compatibility | Perfect fit for specific models | May fit multiple models, not always exact |

| Cost | Generally more expensive | Usually more affordable |

| Warranty | Often covered under manufacturer warranty | Typically comes with limited warranty |

| Availability | May require longer wait times | Widely available through many sellers |

| Durability | Designed for long-term use | Durability depends on the brand |

| Customization | Limited customization options | Often offers more flexibility |

| Performance | Ensures factory-tested performance | Performance can differ by quality |

| Resale Value | Helps maintain original equipment value | May slightly lower resale value |

Electric Motor Repair and Maintenance

If you want any electric motor to last long and serve you well, proper care and maintenance should be done on the motor. Periodically check and examine the motor for any visual signs of premature wear, heat, or unusual sound, since these could be signals of potential faulty parts. Grease the bearings thoroughly, inspect for any connections that need tightening or adjustment, and ensure the motor is clean of any accumulated material. After finding the fault in the calculations, you must always read the manufacturer’s manual and use the valid appliances/ parts. If advanced maintenance and diagnostic checks are required, it would be wise to engage the services of a knowledgeable service provider without risking further damage. Prioritizing maintenance and taking quick action on problems will allow you to keep a low maintenance time and improve operational efficiency.

Routine Maintenance Tips

Lubricate Bearings Regularly

Make sure that the bearings are satisfactorily oiled to lessen the friction and wear of the parts. For interfacing parts, use the lubricant recommended by the manufacturer and maintain the specified intervals, which are generally 6 months or after 500 hours of operation.

Inspect and Tighten Connections

Weak contacts can provide a performance degradation and result in functional abnormalities. Employ a periodic inspection approach for every nut and bolt, including electrical fittings. Carry out this inspection every month to ensure operational safety.

Clean Components to Prevent Debris Accumulation

Another factor that can decrease the performance of parts designed to move is the presence of dirt. Wipe the motor and its surroundings with a clean, damp cloth or use a compressed air blower. This should be done every three months or more frequently in an environment where there is a lot of dust in the air.

Monitor and Replace Wearable Parts

Do not forget to keep an eye on belts, gaskets, and other such replaceable parts in units in use. It’s advisable to do this every three months, and replace any that have been torn/ frayed, or worn out at the earliest.

Test System Performance

Prevail losses before they acquire a critical size. Investigate, also, the presence of unexpected noise, excessive vibration, or thermal stress. Conduct this inspection on a monthly basis to ensure efficient maintenance in the plant.

Check Fluid Levels

System experts should ensure that fluid levels are correct in the vehicle’s system, topping up the levels as necessary. Make it a point to replace the leaking fluid annually, or at the time periods suggested by the manufacturer for maximum effectiveness.

Common Electric Motor Issues

Among the many benefits of electric motors, some drawbacks arise from the equipment not being operated under ideal conditions. For instance, the tendency to overheat, which causes excessive temperature, is primarily caused by the motor’s inadequate cooling or its overload in the system. Another common disadvantage includes wear of the support cage, known as a bearing, which follows contamination, misapplication of the lubricating agent, or unfixing the bearing position and coordination, resulting in vibrational and noisy tendencies. Also commonly encountered are electrical faults, such as insulation failure or winding defects, which are often caused by fluctuations in current levels or deterioration of the electrical components. Apart from the above causes, operational problems can also be caused by misalignment in shafts or loose connections. Solving these issues in advance and adhering to specific maintenance procedures can minimize the wear and tear and enhance the efficiency of the motors.

When to Seek Professional Repair Services

Some situations require professional help to safeguard electric motors from damage and extend their lifespan. It is essential to consult experts in cases of frequent motor-related issues, such as overheating, excessive vibration, or unusual noises, even after receiving proper maintenance service. In addition to this, it would be important to address any significant drops in the motor’s performance, such as low torque or erratic operation, as these could also be indicators of other issues, including the grinding of balls and races, insulation failure, and other malfunctions. One should not despair, as these experts have access to the best testing equipment to identify the root causes quickly. Systems that keep the machine running efficiently and according to set safety operational guidelines can be guaranteed through routine services by trained professionals, thereby reducing the possibility of undue breakdowns and consequent costly losses.

Where to Shop for Electric Motor Parts

It is essential to know and source reliable electric motor accessories, as this plays a significant role in attaining quality and compatibility. Therefore, to get these parts, look for well-known e-tailers dealing with industrial equipment, such as Grainger or even Motion Industries. Most of these platforms offer a variety of items, including accessories, and feature pictures to help you select the perfect item. Alternatively, buyers could check out specialized industrial centers or the authorized dealers of that particular motor make for local options. Maybe Spray Fox experts can help with all these and also provide the spares from the manufacturer. Furthermore, most, if not all, manufacturers can access Spare parts sites for their products, which are made perfectly original to suit them in every inch. It is no harm to check the warranty and how they handle faulty products that are discovered after the products have been purchased.

Online vs Local Shops

When deciding to purchase a motor part in the market, several factors consistently influence the choice between online and local stores. Internet stores offer a bigger variety of goods, better prices, and sometimes a free delivery option. Some websites also include customer product and service evaluations and recommendations that can help you make a sound decision. Local store management allows you to feel and educate yourself concerning the piece you are buying in your hands, with expert assistance from the shop owner. Some local stores also offer counter sales, which is essential in emergency cases. The combination of the conveniences and disadvantages of local and online stores helps to establish the purchase that best fits one’s interest.

Evaluating Quality and Reliability of Parts

Part quality and reliability analysis should assess both vendor-provided technical drawings and results from real working operations. Seek materials and quality requirements according to general industry norms for higher strength and reliability. Consult with an expert for a brief of the customer’s review and expert opinion on how the quality of the component is concerned, and also how suitable it is for a specific condition. Besides, it is important to consider other factors, such as guarantee coverage in terms of the items and the credibility of the company providing the product as well. The use of relevant, up-to-date data enhances decision-making and helps prevent pitfalls.

Tips for Buying Replacement Parts

1. Identify Exact Requirements

Or any other part for that matter, until you are sure of its features and specifications, always ask before buying a replacement for anything. Given that you do not have more of these types of processes, a model for manufacture, or a spare unit handy, the series, dimensions, and other necessary features of parts to purchase help one to avoid buying components that do not fit any machines or systems, or have an inadequate or total capacity of wear parts in use.

2. Research Trusted Brands and Manufacturers

Try getting parts that are from brands that can be recognized for their longevity and quality. It’s also advisable to read customer and professional reviews, as they help in finding the best items and prevent the purchase of substandard products.

3. Compare Prices Across Vendors

Do not be in a hurry to take the first prize that comes your way. Look around for more sellers online or offline to ensure that you access the cheapest; there could be price wars going on between the sellers. This platform, provided by most online shopping sites, offers price matching and discounts, allowing buyers to reduce costs at the same time.

4. Check Warranty Details

Assuring a good try is when the warranty is delivered by the manufacturer, which is proof of the degree of confidence they have in their product. Be certain of getting explicitly defined warranties that cover such expenses, such as defects, malfunctions, and unexpected breakdowns on your part.

5. Consider OEM vs. Aftermarket

There are various categorizations of auto parts. Original Equipment Manufacturer (OEM) parts, also known as so-called OEM parts, are parts made by the same manufacturers who assembled the equipment. OEM parts are a great choice for those who care about quality, as they are specifically designed for the make of the vehicle. However, it is also perfectly acceptable to use aftermarket parts, as described, when they originate from a reputable dealership, which is a more cost-effective option.

6. Evaluate Return and Exchange Policies

In the case of any online purchase, ensure that the seller has defined and clear terms of return and exchange that you, as the buyer, will be satisfied with. This will save the buyer in case a malfunction develops after the part is acquired due to an incorrect order or a defect in it.

Reference Sources

-

Mechanical Design of Electric Machines

- Key Findings: This paper discusses the design and structure of Permanent Magnet (PM) Brushless motors. It highlights the components such as the stator (laminated structure with copper coils) and the rotor (shaft with integrated permanent magnets).

-

A Requirement Engineering Framework for Electric Motors

- Key Findings: The paper presents a framework for selecting and designing electric motors, focusing on surface permanent magnet motors. It highlights the advantages of these motors, such as ease of manufacturing and cost-effectiveness, making them suitable for various applications.

Frequently Asked Questions (FAQs)

Q: How do I find OEM parts for electric motor repair?

A: Locating the original equipment manufacturer (OEM) parts for repairing an electric motor is possible by reaching out to the manufacturer or the authorized vendor. In most cases, they possess materials that can be used to fix the issue and prevent the problem from spreading. There is yet another option. You can embark on a treasure hunt to find top suppliers that specialize in providing replacement parts, primarily for electric and DC motors. Online websites have many local suppliers, and usually several suppliers have the parts available if searching for parts such as fan covers or brake assemblies. Even with repairs being necessary, make sure that your specific model of motor can accommodate and order the required part to replace the damaged one.

Q: What should I consider when selecting motor replacement parts?

A: When picking motor replacement machinery, always check its compatibility with the engine. This can involve checking dimensions, voltage, and even power rating. It is important to go only for the best spare parts, even if it has some hindrance, one should consider another seller for the parts. For motors rated in the NEMA standard, replacement of the parts must surpass that requirement. Consider, too, how many resources will be available in terms of availing support, such as maintenance. Another effective approach is to understand the internal components and their functions. In this way, it becomes very easy to replace and make decisions on the designs of the apparatus, especially in a motor.

Q: Where can I find a reliable shop for electric motor parts?

A: If you are new in a place and looking for a reliable shop to buy all sorts of electric motor spares, this is what you need to do: ask yourself how many motor parts and accessories shops are there online. Usually, there are two types of suppliers: those who deal in original equipment manufacturer (OEM) parts and those who have replicas of motor parts. This type of information is particularly useful, as it ensures that one can expect good service. Apart from locating the shops with motors, there are information providers that can provide services with their AC and DC motors and peripheral parts, which are usually all available. You may also ask for references from the factory technicians or the other industry players.

Q: How can I minimize downtime during electric motor repairs?

A: Beautifully penned! It has long been recognized that comprehensive maintenance and repairs of machinery, particularly electrical equipment, face limitations that impede the need for greater reliance on predictability and preventive maintenance. In our case, such maintenance activities include regular checks for potential issues, which, if left unchecked, could cause downtime. Furthermore, having the necessary motor parts held in stock helps to minimize unnecessary delays. If the crucially demanded parts are in stock and the distributor’s disposal is rapid, then the delay may actually compress the downtime. It also pays to enlighten your employees through training on minor repairs and troubleshooting to save your technological resources from unnecessarily using petty issues to the service providers.