It can be challenging to locate reliable providers of electric motor repair services and motor rewinding when the electric motor has already started to fail and the performance has decreased. Electric motors are essential components of a wide range of appliances present in almost all industries, including households. Hence, these motors have to be maintained whenever they develop any fault. This guide is designed to help reduce the effort required to understand the benefits of rewinding an electric motor, as well as the factors that inform decision-making for the best motor repair services in your region. Irrespective of the trouble that has come, there is always a head count for everything. For that reason, the moment those signs start to manifest themselves, there is no other way than to deal with them immediately.

Understanding Motor Rewinding

One of the primary processes in maintaining an electric motor is rewinding. The purpose of this procedure is to perform the sealing or insulation of a coil winding. In well-constructed motors, it is often the case that only the winding has failed; however, the core, along with the mechanical elements, is still in an operational condition. The process of rewinding is such a high-impact intervention that it restores the original motor to its original state, and on most occasions, the motor outlives the risk of deterioration, thus avoiding the need for a complete replacement of the entire gadget. The process involves removing the old winding, cleaning the core, and installing new coils, reusing the motor. Replacement of the coils in motors is a cost-effective, eco-friendly solution for systems in industrial, commercial, or residential settings.

What is Motor Rewinding?

Repairing and remodeling an electric motor is a productive method not only to restore it, but also to take advantage of the unique benefits that such repair offers. There are several benefits associated with this, the most significant being that it is cost-effective, as rewinding is more affordable than replacing a motor entirely, particularly for large and high-performance motors. Additionally, with the use of modern insulation materials and new winding techniques in a motor, this can occur through thermal insulation that is acceptable to the wires. In such cases, the energy consumption of the motor can also be reduced over the motor’s lifespan. Investing in motor rewinding promotes sustainability by reducing waste and preventing the need for additional new motors, which in turn conserves resources and reduces pollution. For industries that heavily depend on motors for their key operations, motor repair becomes a quick and practical method for maintaining equipment output and reducing operational losses. Year by year, with the introduction of new materials and technologies, the efficiency and service life of rewound motors increase; therefore, they receive recognition from many consumers.

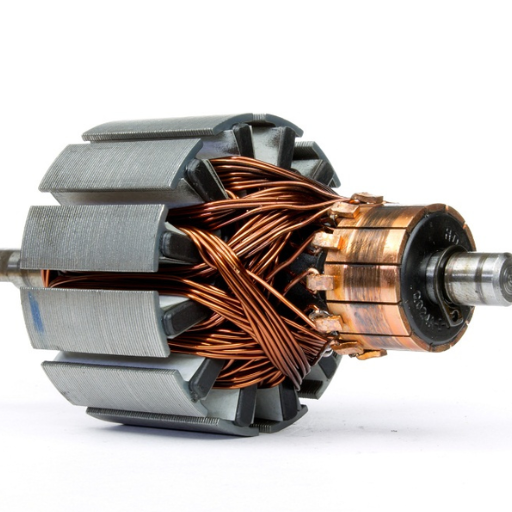

How Electric Motor Rewinding Works

The motor rewinding procedure refers to a comprehensive process where a motor is disassembled to remove the winding components, and defective or old coils are replaced with new ones. A normal beginning of the operation is the removal of winding material; if there is any, the stator or rotor is removed, which is usually done following controlled methods, thereby protecting the core from damage. After the removal of the windings, the core is scrutinized to check for any signs of wear, ensuring it can carry out its intended functions. Next, the new coils are wound and then installed according to the original (or optimized) designs to enhance their efficiency. The coils are further insulated and polymer-coated in order to prevent them from being affected by environmental conditions and electrical challenges. Before the entire package is packed, its functionality, effectiveness, and compliance with industry standards are assessed through examination.

Common Applications of Motor Rewinding

Industrial Machinery

For many sectors, electric motors are used in industrial machinery more than the rest. The wear and tear of the electric motor increases due to the number of times it is used. Thus, Rewinding comes into play since there are numerous electrical systems at various levels of heating and cooling, such as in the industrial sector, construction, or the production of agricultural machinery.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems remain dependent on electric motors for control of compressors, fans, blowers, and several other components. One of the ways to maintain the energy efficiency of the UAE’s ever-expanding building stock is by rewinding these motors.

Pumps and Water Treatment Plants

Pumps are used in the transportation of fluids in various systems, ranging from water supply to waste disposal. Consequently, rewinding is essential for machines, particularly those used in water treatment plants, agriculture, and other industrial and domestic infrastructure.

Electric Generators

Rewinding, as a technique, is a common practice for investing in equipment used in power plants, emergency power supply systems, and renewable energy projects, allowing for repeated use.

Transportation Equipment

The machines used in transportation, specifically tramways, trolley buses, electric cars, etc., like many other technical creations with wheels, are driven by motors that are extremely important in organizing the main and additional transport functions. As a result, it is necessary to apply a rewind instead of purchasing a brand-new motor to avoid the depreciation of this advantage and the associated costs.

Mining Operations

The use of mining equipment for continuous operation under humid climatic conditions is also characteristic of the industry. Attention to wear is minimized with the help of the winding technique, allowing the equipment to operate stably even in harsh environments.

Benefits of Choosing Motor Rewinding

Cost-Effectiveness

Often, the cost of rewinding a motor is lower when compared to purchasing a brand-new one. It also ensures that the existing one remains operational, thereby preventing untimely and expensive purchases.

Energy Efficiency

This can be especially relieving when an energy audit recommends rewinding the motor, and it helps only so much when performed using old methods and components.

Minimized Downtime

In addition, the quick repair and return of motors to operation through rewinding reduces downtime in the company and keeps it on a level pace.

Environmental Responsibility

Reducing surplus by not recycling and manufacturing new motors that have been refurbished through repair or motor winding, rather than purchasing new ones, supports the ideals of sustainability.

Customizability

Because such work is done in-house, it can eliminate the vexation of locating appropriately skilled staff for rewinding in the market.

Cost-Effectiveness of Motor Rewinding

Rewinding motors stands out as a value-adding solution due to the associated cost implications and extended useful life of electric motors. Rewinding or repairing a faulty motor is a more preferable option compared to buying a new one, which can be expensive, and may save costs by at least 40-60%. The other advantage is that rewinding does not involve unnecessary time consumption, as there are service providers who are pretty quick in carrying out this work with little or no disruptions to the processes in use of the motor within the plant. For businesses with a large number of motors to control or manage, the savings would be substantial over the years. In addition, changes in the materials and the way the windings are done have improved motor power factor, whether or not the motor is rewound, in some cases making it possible for such machines to be even better in terms of energy efficiency from the output. This, finally, results in savings on energy costs and operational costs for as long as the motor rewinding service is sought. In other words, investment in the services of motor rewinding is prudent and long-term.

Environmental Impact of Rewinding vs. Replacement

When examining motor rewinding in relation to the environment, it is often possible to identify that the former is more environmentally efficient than purchasing a new motor. The purpose of rewinding a motor is actually to preserve the existing motor structure. In doing so, the amount of new material required is limited. This, in turn, prevents the depletion of natural resources and reduces the emission of air pollutants from motor manufacturers, including harmful gases such as carbon dioxide. Today’s motor rewinding techniques have also helped older motors achieve better energy efficiency and greater performance than they did at the time of their manufacture. The achievement of this has to do with the amount of energy saved during motor operation, and also increases the length at which the motor can be operated before reaching its optimal replacement length. In contrast, motor assembly requires resource extraction, manufacturing, installing parts, and physical shipment. All these aspects add to the carbon footprint of the motors as a whole.

Reducing Downtime with Efficient Repair Services

Avoiding or reducing downtime is a crucial objective for businesses that utilize motor systems in their operations, as it ensures efficiency and productivity. This is mainly because swift action is always required in the event of a fault, to identify the root of the problem and resolve it while minimizing any damage. Stretching available resources to the limit and utilizing the latest technologies in fast interim or major service procedures is another new management approach emerging at present. Recent management strategies envision the application of efficiency-enhancing technologies for the production of goods and the improvement of performance. In general, high-quality assistive and repair services can save approximately a quarter or even a third of the costs associated with each unit of output for the company, as most of the time is spent on manufacturing a unit. Operating and managing industries involve numerous economic activities, including chemical processes, that are aimed at producing various goods and services.

The Electric Motor Rewind Process

Rewinding is an operation that is part of the life of every electric motor. The most basic description of the rewinding process is to disassemble the electric motor, carefully remove the spoiled windings, and fashion new coils that fit into the motor, allowing it to function again. This process is usually initiated by a comprehensive evaluation of the electric motor to assess its condition and determine the cause of winding failure. After removing the old windings, the inner part of the rotor is thoroughly cleaned to improve motor performance. The new windings are appropriately placed, secured, and insulated in the stator. Finally, the stator is assembled and then tested to meet the performance requirements for which the motor was designed. This method is both advantageous and environmentally friendly in that it helps minimize waste and extend the motor’s longevity.

Cutting down on business operational expenses, as well as the cost of buying new equipment, is usually a welcome concept. Instead of replacing an entire machine, its winding is re-repaired, fixing the winding that has outlived its useful life. The process is a cost-effective and efficient way of utilizing downtime, as it requires minimal materials for almost any repair, which is less than what would be needed for an entire motor. Furthermore, rewinding is environmentally friendly and beneficial for resource conservation, particularly the recycling of existing resources. As for the profitability of enterprises, this method helps ensure proper operation without the need for substantial product replacement.

Initial Inspection and Diagnosis

Checking the health of a motor initially involves categorizing any apparent signs of aging, overload problems, or defects with a strong focus before proceeding with maintenance. Inspections of components focus on their windings, sleeve bearings, and connections to identify and prevent any physical defects. After that, some more advanced monitoring devices can be used. This is to detect problems such as misalignment, overheating, and excessive vibration, among others. Electric testing, as well as dielectric and insulation tests, enable the detection of faults or deviations from normal within the windings and other critical components of the provided circuit. The utilization of these precise inspection techniques, combined with the most recent diagnostic technologies, enables the proper assessment of an electric motor’s condition, with the ultimate goal of determining the root causes of failure.

The Rewind Process: Step-by-Step

Initial Assessment

To repair the motor, technicians must first check it, and this may include ip or underground motor assessment or VMI. They check the condition of the motor, measure its resistance value, perform a winding evaluation, and inspect the core or coil for damage. In this way, the preparation is in place for all further checks and work to be carried out after the pieces have been removed from the motor body.

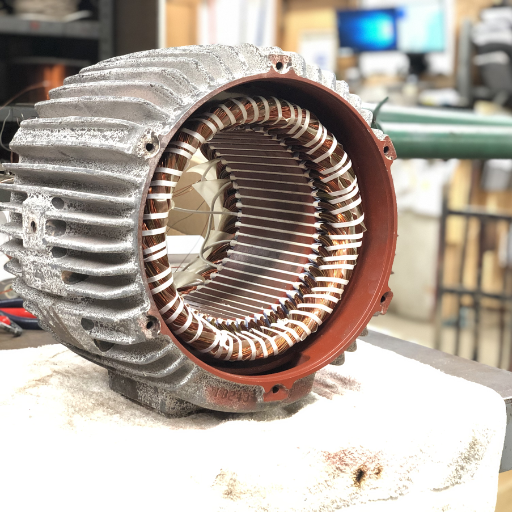

Disassembly and Cleaning

Each component of the motor is carefully disassembled, and every individual component is thoroughly cleaned inside and out to ensure that no dirt, grease, or debris is left. It is for this reason that parts are cleaned before they are evaluated and prepared for use in the motor system.

Core Inspection

Such discernment encompasses whether the core is affected by any defects, for instance, hotspots or interlaminar fragility that may have been aggravated in the past, such as in recent years. Once such damage is identified, it will be corrected and, if necessary, replaced to meet the correct service requirements.

Removing Old Windings

From the stator or rotor, the original tooth windings are gently eased and separated from this element. This stage involves dismantling or cutting off the damaged windings and striking a balance to minimize disturbance to the remaining elements.

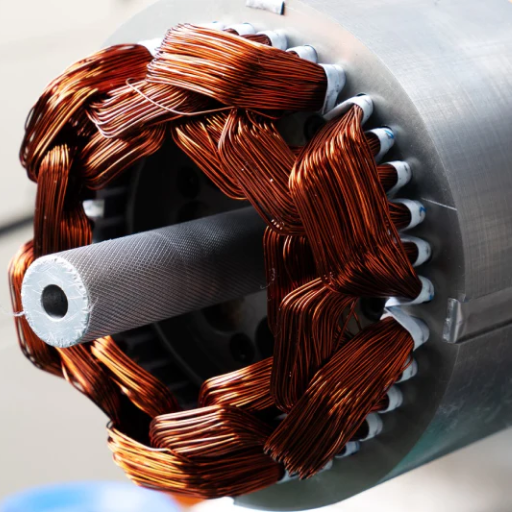

Rewinding with Precision

New coils should be made utilizing. Parts from the appropriate manufacturers and high-quality magnet wire are used in the original design. High-technology solutions, such as wound stator automatic winding machines, help maintain the required orientation of the coils with high precision by applying the correct winding tensions.

Insulation and Varnishing

Every winding is protected by an application of appropriate insulation and vacuum pressure impregnation (VPI) varnish. This process enhances the overall service life of the winding, reduces the likelihood of breakdown, and improves the machine’s heat and electrical capabilities.

Reassembly and Testing

Following the repair process steps, the motor is securely fixed in position after rewinding, and all components are assembled correctly. Once the tests have been run, which involved motor load testing and an efficiency test to verify that the motor performs accurately.

Selecting a Reputable Motor Repair Service

When it comes to hiring a reputable service provider dealing with the repair of electrical motors, there are several other considerations to take into account as follows:

Experience and Expertise

Look for service providers who have the knowledge and experience in repairing electric motors. Always opt for service providers who possess the necessary skills required to handle a specific motor, such as using factory-trained personnel.

Reputation and Reviews

Explore various online sources that tend to promote healthy prejudices, as companies with notable reviews are often those with no negative references.

Comprehensive Services

Re-check the range of services that were promised to be delivered by the consultants – determine if they can perform repair work or maintenance, conduct diagnostics, forward engineering and simulation, and assess the effectiveness of the installed or designed products.

Quality Standards and Certifications

Inspect whether they implement the regulations surrounding the type of work and quality of service they provide, and verify if they have the correct paperwork demonstrating this, such as ISO certification. Or even better, EASA approval.

Warranty and Support

Make sure to note the expected time duration for completion of the work, seek specialists who provide a guarantee for the repair, and assist customers in case of any complications arising from the repair work, if this is an acceptable option for you.

If you consider these aspects, a form of service can be found that will provide the most reliable operation of the electric motor and its longest lifespan.

Key Factors: Certifications and Experience

When assessing the efficiency of car repair solutions, it is the combination of required skills and experience that is considered fundamental. This is because qualifications such as ISO certifications or EASA accreditations demonstrate that a company follows established rules regarding safety, quality, and other factors, as these standards are internationally recognized. On the other hand, an experienced team will be more effective in identifying problems and providing solutions, as they have gained several years of experience working in the field. For these reasons, it is possible to conclude that the repair service here not only meets the demands well, but they also have steps in place to follow in case of hurdles that are experienced, such as emergencies.

Importance of Warranty and Customer Reviews

In motor repair and selection service provision, guarantees and accreditation ratings are also critical factors. A substantial warranty not only represents a policy of the repair work but also belongs to the method of self-conviction of the production in question. Whether it is a short-term, medium-term, long-term, or even lifetime warranty, it alleviates the fears that one may have after spending money. Additionally, customer reviews enhance the account of level diagnoses and dictations from other consumers who have purchased the services. Ratings and lists with highlighted comments help structure reviews and evaluate trends between dependability levels, timeliness, and customer overall contentment. Either of the combinations of these two components within the text will allow for analysis of the service provider’s standards, as well as the management among the consumers.

The Electric Motor Rewinding

Among the most essential aspects to consider when identifying the best electric motor shops for rewinding work are those that prioritize precision, diligence, and the application of modern technology. The most recognized shops have been operating for several years and employ qualified staff who strictly adhere to the market’s rules and regulations. Among the advantages that the motor shop provides is a focus on the quick delivery of motors made from quality materials and serviced to the highest standards, to minimize the client’s downtime. One also needs to find recommendations from within their area or even their country, as well as exhibitions of competence and professionalism, and confirm membership to a professional body. Lastly, to ensure customers get value for the services they need, the contractor must have the right equipment in place to facilitate the correct diagnosis of any motor malfunction that may arise during the operation.

Types of Motor Rewind

| Type of Motor Rewind | Key Points | Parameters to Consider |

|---|---|---|

| Full Rewind | Replaces all windings in the motor. | Time-consuming, long-term solution. |

| Partial Rewind | Repairs only specific damaged windings. | Faster, cost-effective option. |

| Stator Rewind | Focuses on rewinding the motor stator. | Affects efficiency and performance. |

| Rotor Rewind | Restores functionality of the motor rotor. | Requires careful alignment. |

| Random Wound Rewind | Windings placed without a precise pattern. | Common in small motors. |

| Formed Coil Rewind | Uses pre-formed coils for uniformity. | Ideal for large industrial motors. |

| Single-Phase Motor Rewind | Specific to single-phase motor systems. | Common in household appliances. |

| Three-Phase Motor Rewind | Designed for three-phase motors in industries. | Enhances power and efficiency. |

| High Voltage Motor Rewind | Rewinding for motors operating at high voltages. | Ensures insulation reliability. |

| Low Voltage Motor Rewind | Tailored for motors with low voltage requirements. | Suitable for small-scale applications. |

Summarizing the Benefits of Motor Rewinding

Motor rewinding is recognized as a valuable option because it maintains motor efficiency and extends motor lifespan at a cost-effective rate. Defects in motors can be fixed, resulting in minimal downtime and lower costs for spares and repairs. Findings establish that reconditioning motors may return up to 95% of the motor’s original efficiency, thereby obviating the need to purchase a new one. Furthermore, the rewinding process enhances environmental preservation by minimizing product waste, reducing energy consumption during the production phase, and promoting material reuse. Incorporating modern motor rewinding technology and compounds, in line with commercial policies, in most cases results in increased durability, enhanced performance, and cost savings over the long run. Therefore, it is sufficient for sectors keen on improving performance and environmental protection to encourage the adoption of this technology in industries.

Encouraging Informed Action for Motor Repair

When it comes to machine repairs, understanding the nuances of the machinery and determining the best course of action in connection with the broken-down machine are crucial. Recognizing that it is challenging to be very accurate without a proper linking of infrastructure, finding some applicable industry-specific guidelines or information that will provide a clue on whether to engage a service provider, order a rewind, or replace the component or machine. Moreover, it is advisable to study sustainable and cost-efficient energy use case studies, which will help make both logical and strategic choices. By leveraging current approaches, there is potential for gains in motor utilization and efficiency, as well as savings on repairs. Institutions that maintain their equipment in good condition are unlikely to incur unnecessary losses in the form of downtime and high ownership costs.

Reference Sources

-

Analysis of energy savings for rewinding and replacement of industrial motor

- Key Findings: This study examines the energy efficiency implications of rewinding versus replacing industrial motors. It highlights that while rewinding can lead to some efficiency degradation, proper techniques can minimize losses.

-

Assessing the impacts of rewind and repeated rewinds on induction motors

- Key Findings: The study investigates the effects of multiple rewinding cycles on induction motors, finding that repeated rewinds can lead to increased motor losses. It suggests that redesigning motors during the rewinding process could be a missed opportunity for improving efficiency.

Frequently Asked Questions (FAQs)

Q: How can I find a motor repair service near me?

A: Looking for a good quality motor repair service is quite simple with the quick query “near me motor repair”. It is recommended to find local machine workshops that conduct preventative maintenance or some form of refurbishment of engines or electric motors. Most of them concentrate on fault finding, preventive maintenance, enhancement, and modification of electric motors, fans, and blowers. Hull balancing, spooling. Vibration monitoring is carried out on some equipment to ensure its proper functioning. Another critical factor is getting customer reviews and rating scores on the delivery mechanism. Some machine shops often offer free consultations or estimates to allow clients to test their capabilities against what they are advertising. Also, remember to ask about their experience with certain types of motors, such as AC and DC motors, regardless of whether they have dealt with them or not.

Q: What does the electric motor rewind process involve?

A: The process of rewinding an electric motor is a complicated one and consists of specific, strict actions that will ensure the motor becomes just as good as it was when it was new. To begin with, the motor is dismantled and the armature is examined for any signs of wear and tear. As a result, coils with damage are replaced, and the winding process is then meticulously performed to ensure accuracy. After that, the motor is cleaned and improved to eliminate all harmful pollutants that can compromise the machine’s performance. Once the equipment is assembled, various tests are performed to determine the condition of the motor. This operation helps restore the function of aged machines and improve their performance for many more years.

Q: What types of motors can your motor rewinding shop restore?

A: The motor rewinding shop that I own can restore different types of electric motors, including industrial alternatives, such as AC and DC, and servo motors, as well as pumps. We can provide professional and certified electric motor rewinding services, including small equipment and large industrial applications. Our erectors are familiar with the apparatuses of all types of mechanical equipment, providing maintenance and repair. Regardless of whether your machine just needs one part replaced or requires a complete overhaul, we are the industry leader. Additionally, we have included preventive maintenance in our list of services, which helps increase equipment efficiency and reduce breakdowns.

Q: What should I consider when choosing electric motor repair services?

A: In the process of selecting an electric motor repair provider, it is necessary to pay attention to the service personnel’s experience and qualifications. In this case, a shop known for its expertise in motor rewinding services, particularly in this area, should be identified. Consider the range of services, such as checking, dynamic balancing, and renovation, and also ask how the shop has been performing. Additionally, inquire about whether they offer a one-stop service that caters to a broader range of motor types and if they have experience with modern techniques such as CNC machining. Lastly, do not forget to enquire about the guarantee in the case of repair and whether they are client-sensitive. Request detailed information, including prices and all services, to determine if there are alternatives or to sign any orders along the way.