Power systems use three-phase power quite often to maximize their efficiency in industrial and commercial setups. However, from another side, single-phase power is the most commonly available power source both in residential and rural regions. This is where the negative side of using the three-phase power for machinery or equipment in such areas arises. This is when the technology of the phase converter comes into play. There are various applications that Phase Converter technology opens up and this article will look at the principles of phase converters, the role of this technology, and the main criteria for the perfect choice of the converter in terms of your application. By the end of this knowledge-sharing session, you will have a good idea of the working of the Phase Converters, their different embodiments, and how they can add value to your operations by consistently supplying sophisticated and cardinally scalable power solutions.

Understanding Phase Conversion

Phase conversion is converting single-phase electrical power into three-phase power, as required by machines that support three-phase systems. The transformation is made by a device called a phase converter. Single-phase power has a high distribution rate and is used mainly in residential and small commercial settings, while three-phase power, largely because of its efficiency and loading capability, is the most common type of power used in industrial applications. The converter industry has provided the perfect solution by devising ways to convert the incompatible power supply in order to cater for both types of machinery, thus enabling three-phase machines to run in zones where single-phase power only is being supplied.

What is a Phase Converter?

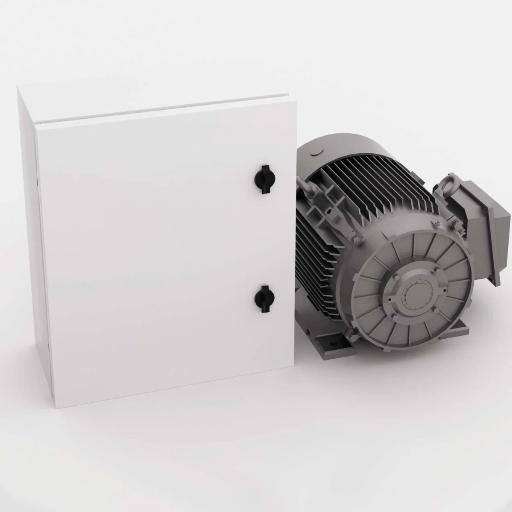

A phase converter is simply termed as a converter in an electrical unit which is used to change single-phase electricity into three-phase electricity allowing the operation of three-phase machinery in places where there is limited or no power infrastructure. These are the usual static, rotary, or digital methods by which the conversion is done. Static converters use capacitors for momentary phase shifting when starting the motor, but they are not very efficient in maintaining continuous three-phase power. Rotary converters use an idler motor for giving a third phase, which provides more stable and robust power suitable for varying loads. Digital converters use advanced microprocessors to give a very precise, well-balanced three-phase power, ensuring a constant performance level and energy efficiency.

In industries like manufacturing, agriculture, and woodworking, which mainly depend on three-phase machinery in their processes, these converters are an inevitable part, but most of the time the three-phase utility connection is not available.

Components of a Phase Converter

| Component | Description |

|---|---|

| Static Converter Module | Initiates phase conversion process using capacitors. |

| Digital Controller | Manages precise balance of three-phase power output. |

| Idler Motor | Creates a rotating magnetic field for phase shift. |

| Capacitor Bank | Stores and manages electrical charge for stable operation. |

| Voltage Stabilizer | Ensures consistent voltage levels across all phases. |

| Cooling System | Prevents overheating during extended operation. |

| Input Electrical Panel | Connects single-phase input to the converter system. |

| Output Terminals | Delivers converted three-phase power to connected equipment. |

| Overload Protection System | Shields components from excessive current conditions. |

| Enclosure | Protects internal components from physical and environmental damage. |

The Importance of Phase Power

Phase power is one of the most important aspects in industrial and commercial electrical systems, with a direct impact on the performance, efficiency, and reliability of equipment. Three-phase power is especially appreciated for being able to provide an even and balanced power source all the time, hence, minimizing the power losses and making it possible to use the heavy machinery with the totally diminished less power. However, the single-phase systems are prone to power losses and, hence, power generation, which are major drawbacks. Three-phase systems take care of the power distribution among the phases very evenly, hence operating with the lowest possible loss of power.

In general, the industrial sectors that make use of machinery like motors, pumps, compressors, etc., will really appreciate the stable torque and energy delivered by the three-phase power. For instance, securing a steady power supply for CNC machines and conveyor systems is the main reason why three-phase systems are widely accepted in manufacturing sector and agricultural sectorings equally make use of three-phase power for most of their operations such as pumps for irrigation and equipment used for processing.

Moreover, the reduction of power quality issues and the keeping of voltage imbalances to a minimum by the use of three-phase power systems lower the maintenance cost thereby extending the life of machinery, besides getting rid of milder and tear as a result the exploitation of the same of machinery. Through the efficient power management environment that they create, they are always considered not only cost-saving but also profit-making.

Main classifications of phase changers

- Rotary Phase Converters: Rotary phase converters which are described as one type of converter type that uses an idler motor to generate a balanced three-phase power supply from a single-phase input are reliable and versatile, which is why they are most commonly used for hard and difficult work like heavy machinery, CNC equipment, pumps, etc.

- Static Phase Converters: Static phase converters, on the other hand, start three-phase motors using capacitors which is a very much simplified approach to the process. It is worth noting, however, that these devices should not be used to power anything more than a light-duty application, as they do not produce a true three-phase power output.

- Digital Phase Converters: Digital phase converters are a group of converters that are different from the other types as they completely rely and hand over the control of the three phase voltages to the master controller. They give the most stable and efficient power and are suitable for places vulnerable to electrical disturbances, i.e., with sensitive electronic equipment.

Static Phase Converters

Using static phase converters can be an inexpensive way to operate three-phase motors on single-phase power. They operate by the employment of capacitors that give the necessary initial phase shift to start the motor. After the motor has attained about 75% of its normal speed, the converter stops its operation, and the motor power continues to be provided from the single phase with a later-reduced speed which means reduced efficiency also.

Static phase converters are easy to install and easy to operate but are not the best choice for applications where the motor works at its full load capacity. If the load gets heavy, the resultant power reduction can cause inefficiency, overheating and motor wear. Apart from this, static converters are not the proper medium for sensitive equipment or processing that asks for continuous three-phase power performance. Still, simplicity is their strong point, and they can be a useful option for places where three-phase power is only occasionally needed or the applications are light-duty. The rotary or digital phase converters are usually the choice for the more critical and heavier applications among the rotary converters and digital phase converters.

Rotary Phase Converters

Rotary phase converters are sophisticated single-to-three-phase power conversion devices with a wide range of applications. More specifically, it becomes feasible to employ the three-phase devices in regions supplied only with single-phase service. A motor generator set is what rotary converters employ in order to produce genuine three-phase power and the latter will consequently guarantee a properly balanced voltage at the same time. Thereupon, it is also the case that anybody who purchases or uses them may find their smooth performance quite advantageous in the various heavy machinery, CNC equipment, etc., applications of high industrial demand.

It can be said that the strength of CNC phase converters is the fact that they can provide stable and continuous power supply with the least distortion of harmonics, so that basically they can be used with any kind of machinery. The modern rotary converters have built-in technology which allows automatic voltage balancing among the phases and power monitoring. Their sturdy construction helps them to cope with varying loads in a most effective way and they are suitable for tough environmental conditions in terms of both durability and longevity.

In order to choose a rotary phase converter, besides the total horsepower of the equipment, the starting load requirements, and the specific operational needs of the machinery, there are the other factors to be taken into account as well. It is the correct dimensioning and the way of the converter being put, that are key to the perfect performance and absence of any inefficiencies that might cause the overheating of the equipment or could damage it. For industrial and commercial three-phase power applications that are in need of a reliable source, the rotary phase converters still stand out as a very good option.

Digital Phase Converters

Digital phase converters are a very advanced way of converting from single-phase to three-phase power by the utilization of the super modern microprocessor technology to improve the efficiency and precision. These devices are also monitoring and controlling voltage and thus guaranteeing the best performance, which is possible only through the utilization of the most technologically demanding industrial and commercial machinery. With the traditional rotary systems, this is completely different as digital phase converters only offer a better voltage balancing and less harmonic distortion that is very important for sensitive equipment like CNC machines, elevators, and automation.

One very important advantage of digital phase converters is the fact that they are able to adjust to different workloads immediately so as to keep the power quality optimal without human intervention. Not only do most models have a series of self-checking devices and protective elements by default, like for example current overloading and loss of phase detection, but, also, they are designed in a way that they require very small space and still are very light so that they are most suitable for places where space is at a premium or where there is a need for taking it from one place to another. Along with the advantageous features and versatile configurations, digital phase converters are now quickly becoming the best option of the facilities that wants the power solutions to be safe, reliable, and at the same time to be scaled up.

Technical Benefits of Phase Conversion

Phase conversion is a way of making good use of power while making three-phase equipment work in places with only single-phase power supply. By doing this, it eliminates the need for expensive infrastructure upgrades, but at the same time, keeps the equipment performance and life span at their best. Furthermore, the phase converters also work well with the power consistency, seeing that they reduce the voltage fluctuations that can end up in equipment damage or inefficiency. Apart from that, the phase converter’s capability to support variable loads guarantees the best performance that is suitable for various industrial applications. The above-mentioned advantages show that phase conversion is a valid and economical choice for industries which need reliable and versatile power.

Motor Efficiency Improvements

Improving motor efficiency is a key determinant to lessening energy consumption as well as operational costs in the industrial sector. With the same token, the energy conversion efficiency has been largely increased as a result of the rotor and stator geometry being optimized. The high-efficiency motors corresponding to the standards IE3 and IE4 have become reality mainly due to better materials, finer manufacturing, and smarter insulation. High-efficiency motors may as well, on the average, save up to 30% of power consumption, from the data provided by the industries. By the same token, the use of variable frequency drives (VFDs) makes it a doable thing to monitor motor speed closely by regulating only the needed motor and not the constant full load, the latter being the case when one has to save energy. These changes coming to light show ‘taking-up’ the highest-tech motors for a better output and cost-efficient energy as already happening and will continue to increase environmentally friendly status.

Enhanced Equipment Compatibility

The motor systems of the modern era are engineered to easily merge with a wide variety of industrial equipment which ensures an exceptional compatibility among various applications. Such systems have data exchange efficiently through the use of advanced communication protocols like Modbus, Ethernet/IP, and Profibus, and thus in a real-time monitoring and diagnostics with their compatibility enhancement. That’s, the latter two are crucial for predictive maintenance strategies and downtime minimizing, respectively. In addition, the contemporary motor technologies are so designed that the modular characteristics allow for easy upgrades and expansions, ensuring that systems will accommodate the changes in operational demands. The totality of compatibility features not only enhance the reliability of a system but also improve the performance and the workflow in the complex industrial environments as well.

Performance of 3-Phase Motors

A 3-phase motor’s effectiveness is primarily determined by its efficiency, power output, and stability during operation under a variety of industrial and commercial applications. These motors are greatly valued for their very good torque properties, which makes the start-up process smooth and at the same time, operation is mostly consistent at different load conditions. Energy efficiency—modern 3-phase motors can get over 95%, especially when high-tech materials and engineering are used—is a significant merit, since it enables the user to control the energy consumption to a great extent.

The main factor that makes the performance of a 3-phase motor is its power distribution, so that the three phases balance each other, which in turn minimizes the vibration and hence less wear on the mechanical parts. By using a power factor that is near one, the motor can be said to be operating at a high power factor and thereby mostly at peak efficiency, even during torque and speed fluctuations, in other words, bad conditions within the motor.

The development in variable frequency drive (VFD) technology is making a huge difference in the controllability of 3-phase motors, thus making it possible to have the exact speed and being able to still practice in dynamic environments better than before. Also, these motors are staying operational longer due to the very tough insulation systems and heat management technologies, which stop the most common failure causes such as overheating and electrical arcing. In general, advanced engineering features in addition to great efficiency make 3-phase motors the number 1 choice for industries that have high requirements, could count on reliability and are looking for the economy of performance.

Economic Advantages of Converting to 3 Phase

Converting to a 3-phase power system has numerous economic benefits because it contributes greatly to industrial and commercial applications. For one, 3-phase systems are by design more productive which in turn results in decreased energy losses during transmission and operation. The gains in this aspect are eventually seen in the form of the user having to pay less for energy. Moreover, appliances and machinery that are 3-phase are usually easier to maintain and have fewer breakdown problems, thus, they lead to less time of being off duty and the cost of repairs is more likely to be lessened.

One more reason is the fact that, when compared to single-phase systems, these power systems use thinner wiring that is cheaper and less complicated. Thus the installation costs will also be lessened. In addition to the above, businesses can also look forward to the possibility of the company being designed according to its power need since 3-phase power means the capability to have higher loads and this is so useful if the company is planning to increase its production without undergoing any major changes in the infrastructure.

Cost Savings in Industrial Applications of Converting to 3 Phase

The change to a 3-phase power grid can vastly improve industrial work by saving a lot of energy. Really, a 3-phase system is considerably better than a single-phase one because, applied in industry, it prevents the wastage of energy, thus, reducing the cost of electricity and, consequently, the power bill. Research has also pointed out that employing 3-phase power can help to diminish the energy consumption of equipment, as it delivers power more evenly and puts less strain on these machines, which is the direct cause of cost savings.

At the same time, using thinner wires and smaller electrical components in 3-phase power systems is another way to cut the initial costs and eases the maintenance conditions. Efficiency gains from electric power consumption are significant among facilities working with heavy-duty equipment like induction motors and HVAC systems. Surely, some companies even derive benefits from reduced expenses that are really high due to the conversion to three-phase power supply from the energy-saving and demand-reducing point of view.

Long-Term Investment Value

Switching to a 3-phase power system is one of the major step you can take that not only would have a huge impact on the efficiency but also the operation cost saving for the entire period. Normally seen as major constraint in the way of carrying heavy loadings, single phase systems don’t have that issue with the 3-phase system. The thing that makes 3-phase power supply special is that it gives a continuous and balanced supply of electrical power which is perfect for a huge quantity of industrial and commercial users that require strong and stable power. Research has shown that by utilizing 3-phase power systems, it is possible to reduce the energy losses as they can carry more power with smaller conductors, thereby finally reducing the electricity bills.

3-Phase equipment will have longevity with less wear and tear hence reducing maintenance and Replacement cost in the long run at the same time. 3-Phase systems have the capacity for future developments, this is a good investment for the growth of the company. For example, industries that are using 3-Phase power in their plants will have the advantage of smoother motor operation, increase power density, and a better overall system reliability, which are the main criteria in upholding productivity and ensuring a company’s continued operation, especially in harsh environments.

Reducing Operational Downtime

One must engage in meticulous planning and incorporate the best practices that would comply with the industrial standards so that the operational downtime would be minimized during the transition to a 3-phase power system. The power capacity is a concern and avoiding it will be a solution since there will be difficulty in coping with high-demand power at that time. By doing the energy analysis and load assessment before that period come, the system will most likely be found to be insufficient and therefore timely steps could be taken to alleviate the situation by, for instance, replacing transformers, generators, or feed lines.

Equipment testing and the verification of the compatibility between the existing and new equipment ahead of any conversion were found to be very important. Modern technology, like the temporary bypass systems and the portable power solutions, at the proper time of the installation can rely to keep the essential services running. Studies carried out showed that companies using predictive maintenance practices and real-time monitoring systems in their conversions had 35-% less downtime than those who did not.

Selecting the Proper Phase Converter

When you shop for a phase converter, it is a fundamental requirement to check the power demands of the equipment and the environment of the operation. One of the ways you can start is by calculating the sum of the motor horsepower and amperage consumption of the machines for the sake of the converter’s wattage matching with your power system’s intensity. Rotary converters are mostly seen to be a perfect recommendation for tasks necessitating hassle-free, power in good balance at different machinery and single-phase converters are apt for less draw-heavy, one-motor operations.

Moreover, check for the quality of the output power provided by the phase converter. Machines that feed on precise power such as CNC machining bars often need the type of converter that gives the stable and clean power to maintain the performance of the equipment and protect the components. In a similar way, the power to keep the equipment up and running during time, and therefore, the environmental factors such as the variations and exposure to dust or moisture, should also find a significant role in directing your choice as these conditions very well can have a continuous impact on long-term reliability.

If you meticulously and appropriately select the converter type according to your equipment’s needs and operational conditions, you will realize the highest efficiency, the least breakdown periods, and the longest life for your system.

Expert Tips for Choosing a Converter

- Determine the Power Requirements

Check the power rating and the current requirements of the equipment, as the transformer is to give enough power. As an example, a transformer that is rated 12V input, 24V output, and 5 A would be good for devices that need power up to 120W. - Consider Efficiency Ratings

Taking advantage of high-efficiency converters is also a way to reduce energy wastage along the line of heat and hence, improve operational efficiency while cutting costs. To make it simple, anything with an efficiency of 85% and above is going to waste very little power. - Evaluate Load Variability

Prefer a converter whose performance remains almost the same, whether the load is changing or not, by the need of the applications. A ±1% or better load regulation spec is very good for the delicate electronics. - Inspect Environmental Durability

The converter must have a power rating that is appropriate for the environmental conditions in your location. For illustration purposes, dusty and wet environments most of the time may require converters that are IP65 or IP67-rated to protect against dust and water. - Focus on Thermal Management

Go for the converters that have effective cooling solutions like the ones with a built-in heat sink or a forced-air cooling system. A converter that is designed to work up to 85°C should have good thermal management for a long service life. - Check Certification and Compliance

Make sure to follow the given regulations of standard bodies like UL, CE, or FCC. Being compliant with such certifications ensures not only safety but also compatibility with international regulations.

Understanding Your Power Supply Needs

Determining the power supply that needs to be fed the essential power is a vital mission just where main parameters and performance needs of the application have to be brought into consideration. The main thing is to see the voltage and current ranges and the necessary stability there to ensure that the supply can give the power needed without crossing its operational limits. In sensitive electronics, no less than 0.1% output voltage precision should be provided in the supply. However, the highly power-consuming devices may need supplies with current ratings up to 10A or even more than that.

In addition, consider the identification of the kind of load that the power supply will handle – static systems’ load is far distinct from that of motors, which are dynamic loads and undergo power variations. In this context, think of the transient response requirements because the power supply needs to settle output quickly during sudden load variations and keep the system reliable.

It is also crucial to think about efficiency ratings and thermal performance, especially when the systems are running under high loads for long extended periods. The equipment that has higher efficiency causes less energy waste and generates less heat which then results in the longer life of the whole operation and the lower energy costs. The agreement should be verified to be compatible with its energy specification and standards such as 80 PLUS and Energy Star.

In the end, you would also have to name the environmental conditions apart from temperature, humidity, and possible dust or vibration exposures. Cases or enclosures that have proper ingress protection (IP) ratings and power supplies that have a quite wide range of operating temperatures are among the necessary qualities for severe environments. These are the intricate assessments that ensure the power supply to be selected will align perfectly with the functional, regulatory, and environmental requirements.

Reference Sources

- “Three-phase to single-phase power-conversion system”

Read more on IEEE Xplore - “Control of single-phase and three-phase DC/AC converters”

Read more on ScienceDirect

Frequently Asked Questions (FAQs)

What is a phase converter, and how does it work?

A phase converter is a device that converts single-phase power to three-phase power; for instance, a rotary phase converter or a digital phase converter. It converts the single-phase power to three-phase power for the applications of 3-phase power motors and equipment. Even small users like hobbyists with units of 3 hp or 10 hp can have their very low power demands met, most especially when it is a milling or CNC which is a typical case, while on the other hand, the VFDs, which are either rotary or solid-state charged, installed in large industrial machines and serve several loads and bigger motors. When it comes to the installation, many factors play a part; these include wire size, amp limits, as well as the use of UL-listed equipment and a contactor for safe switching.

Can I run a 220V single-phase machine on 3-phase using a power converter?

Indeed, a lot of phase converters and power converter solutions can be used to convert a single-phase 220V or 240V to three-phase, if the 3ph 220V or 240V is needed by the equipment. To size the converter up properly, you need to verify the type of load applications and motor rating including hp and rpm for inductive or resistive loads like a welder or motor-driven lathe. There are also applications in which the use of PLC control or NEMA-rated contactors is necessary for the management of multiple loads and the issue of UL listed compliance. When you have the need for a precise motor speed control, a VFD or digital phase converter would be a better choice of more highly efficient than a basic rotary converter.

Is a VFD better than a rotary phase converter for single-phase to three-phase conversion?

Voltage Drives, as is often the case, offers the facility to be a single-to-three-phase converter, along with providing motor speed control and increased motor efficiency if we come close to a regular rotary-type phase converter. Besides this, they create new availability through their Single-phase power to three-phase power operational feature. The Variable frequency drives are solid-state and in most places certified by the Underwriters Laboratory, making them usable for high-tech applications like CNC machines and also for being the solution for the motor speed and the torque control along different RPM ranges. Still, Variable frequency drives may have current and voltage limits in comparison to a rotary converter with only the basic level of control.

What phase converter size do I need for my motor (hp: 3hp, 10hp)?

To achieve a phase converter sized according to or greater than the size of the largest motor hp that you plan to use; you might find that a 3 hp motor often is connected to a small 3 phase converter, while a 10 hp or higher-sized motor requires a larger rotary phase converter or even an engineered one. In case of many loads or the largest motor in a workshop service, choose capacity that will not only be enough for inrush currents and the highest amp draw but also for the startup and running of additional 1 to 3 converters. Safety and code issues will be effectively resolved by using UL listed equipment and proper contactors, and these factors may even help you choose a rotary type for load that is not so frequent.