When people talk about electric devices, the first thing that comes to their minds is the necessity of knowing the difference between a rectifier and a converter, especially for engineers, hobbyists, and anyone involved in electronics. This is because, although these two terms are often used interchangeably, they each have unique and applicable functions that primarily determine their existence in power systems, industrial machines, and everyday electronic devices. The post you are reading now is dedicated to the main distinctions between rectifiers and converters, thus helping you understand their qualities, working principles, and best venues for their use. Whether your motivation is to enhance your tech-savvy or to gain practical tips for your specific projects, this write-up offers a straightforward and uncluttered comparison to reveal the influential roles of these two gadgets.

Introduction to Power Conversion

The transformation of power is a process whereby the electrical energy is molded into a different form that meets the requirements of a particular application. At times, this may include switching electrical power from alternating current (AC) to direct current (DC), and vice versa, as well as changing both voltage and frequency. Converters and rectifiers are the two main types of devices used in power conversion. To be more specific, rectifiers are the ones that convert AC into DC, which is necessary for devices needing a steady and one-directional current. On the other side of the coin, converters may deal with a wide array of transformations, including voltage alteration and AC/DC exchange. Effectively carrying out the conversion process is a prerequisite for achieving the desired performance in electronics, industrial equipment, and commercial energy systems.

What is a Rectifier?

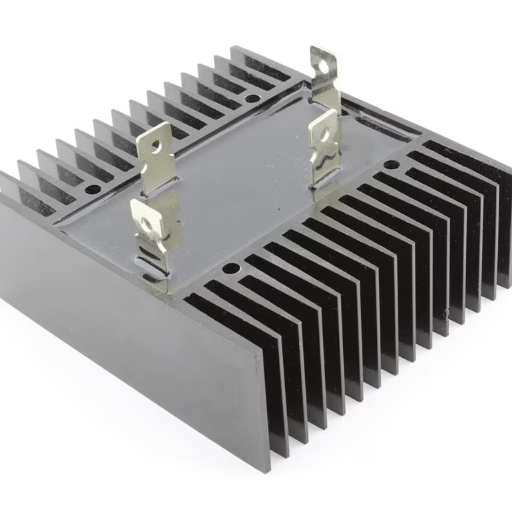

A rectifier is a power circuit that linearly converts AC to DC, with the AC component being close to ground potential through the alternator or transformer. The ac voltage source current changes direction due to its nature of alternating, whereas the current from the dc source flows in one direction only, which is why it is referred to as direct. This is one of the reasons why diodes are used as essential components in rectifying circuits. Together with the diode, they form a bridge that allows current to conduct in one direction, thus achieving the conversion of AC to DC.

Power systems and electronic devices rely on and support rectifiers to function effectively; electrical equipment that requires DC power includes batteries, motor drives, and communication technology. A rectifier can be classified into two major types: half-wave and full-wave, which are based on the design and efficiency considerations of AC to DC conversion, among others. Early in the days of single-phase rectification, a half-wave was common, followed by the full-wave diode, as it was more efficient in terms of the amount of DC delivered. The rapid pace of rectifier development is presumed to be associated with the necessity for modern electronic systems to consume less energy while providing reliable performance.

What is a Converter?

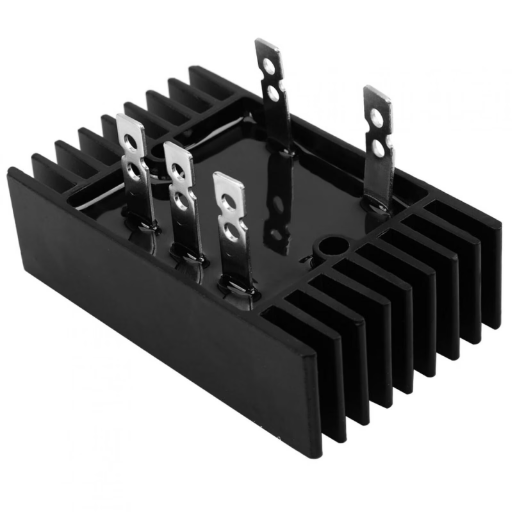

A converter is an electrical device or circuit responsible for changing energy from one type to another, thereby serving different power requirements in power systems and electronic applications. Converters are mainly used to change voltage levels, frequencies, or current types, so that other devices or systems can be used together.

Depending on the function, they can be divided into different groups such as AC-DC converters (rectifiers), DC-AC converters (inverters), and DC-DC converters (choppers). The modern advanced converters are integral to renewable energy systems, such as solar and wind, where they are at the forefront of the battle for efficient energy consumption and delivery. State-of-the-art converters are increasingly being developed to make energy consumption more efficient, reduce losses, and accommodate the rising demand for eco-friendly and reliable power solutions.

Role of Inverters in Power Systems

Inverters, often called the yin-yang of power systems, convert direct current (DC) into alternating current (AC), which is necessary for most household appliances and industrial machines. Their role in the power supply is crucial for renewable energy, such as a PV solar system, where they enable the DC power from the sun to be used by AC-receptive devices or connected to the electrical grid. The modern-day inverters come with the most innovative features, like maximum power point tracking (MPPT) to maximize energy production and grid-tie capability to guarantee effortless integration with current power networks. These inverters are increasingly being designed to integrate into innovative grid technologies, introducing real-time monitoring, fault detection, and power management functions. Moreover, innovations in inverter technology have led to increased energy efficiency, size reduction, and lower operational costs, further boosting their popularity in sustainable energy solutions.

Difference Between Rectifiers and Converters

Rectifiers and converters are both essential for the control of electrical energy, despite having different working principles. A rectifier converts AC into DC, which is the standard current type for battery chargers and electronic device power supplies. Conversely, converters are much more flexible as they can simultaneously perform several functions, such as DC-AC and AC-DC conversions, and even change current characteristics, like voltage or frequency. Although rectifiers specifically address the AC-DC conversion issue to the point of being a subset of converters, converters possess a wider range of functionalities, accommodating the broader spectrum of energy conversion requirements.

Key Differences Explained

| Parameter | Rectifiers | Converters |

|---|---|---|

| Primary Function | Converts AC to DC only | Converts energy between AC and DC, or adjusts voltage/frequency |

| Scope of Use | Limited to AC to DC transformation | Broader energy conversion applications |

| Directionality | Unidirectional energy flow | Bi- or unidirectional energy flow |

| Usage Examples | Battery charging, electronic devices | Renewable energy systems, motor drives |

| Complexity | Less complex and specific | More complex, versatile functionality |

| Output | DC output only | AC or DC output, depending on requirement |

| Efficiency | High for AC to DC | Varies based on conversion type |

| Design | Simpler circuit design | Advanced circuitry and engineering |

Rectifier Circuit vs Converter Circuit

Rectifier circuits and converter circuits differ in the applications they find based on their functionality and energy conversion capabilities. Rectifier circuits are mainly found in the power supplies of electronic devices. The conversion from AC to DC is a must here. For example, charging systems for mobile devices, laptops, and other gadgets that work on DC power cannot do without rectifiers. Rectifier circuits are still powering the daily electronics due to their simpler design and high efficiency in AC to DC conversion.

On the other hand, converter circuits capable of performing precise energy conversions between AC and DC or adjusting voltage levels at will have broad applications in renewable energy systems, such as solar power installations. Thus, these circuits allow the energy produced to be stored and used in a controlled manner, ensuring it fits the system’s needs. They are also the main component in the case of electric vehicles (EVs), motor drives, and other advanced industrial applications where flexibility and precision in energy management are the key. The continuous advancements in circuit technology now make converters more effective, offering better energy savings and more sustainable solutions for modern energy needs.

Common Misconceptions

One of the most common errors in thinking about power converters is the idea that they are one-size-fits-all. It is a common belief that all applications can be covered with a single converter that can handle all kinds of voltage and current requirements. Contrary to that, power converters are highly specialized, and each type is designed for specific performance requirements.

Another wrong notion is that power converters are inefficient by nature. Some models performed poorly, but now modern converters achieve remarkable energy efficiency levels, thanks to semiconductor technology and advanced designs. The last misconception is that power converters are unreliable or easily fail under harsh conditions. On the other hand, the continuous development of thermal management and the selection of rugged materials have enabled them to not only survive but also conquer the hardships of industrial and environmental domains.

Applications in Electronics

Power converters are crucial for various electronic applications because they efficiently transfer energy and maintain compatibility between different components. Regulating voltage and providing stable power are functions performed by power converters that are widely used in laptops, smartphones, and LED lighting systems. Besides, power converters’ ability to process power smoothly makes them integral to renewable energy systems, serving as the interface for solar panels and wind turbines to connect to the power grid. Their reliability in performance and energy efficiency has made them unavoidable elements in both consumer electronics and industrial applications.

Use of Rectifiers in Power Supply

A rectifier that performs AC to DC conversion is a crucial system component in the power supply required for the operation of most electronic devices. Such devices find a place in applications ranging from small-scale home electronics to large industrial power systems. Silicon-controlled rectifiers (SCRs) and Schottky diodes – the posh modern rectifiers offer even higher efficiency and reliability. The evolution of rectifier design has worked wonders in thermal management. It has effectively curtailed energy losses, making them highly effective in sustainable energy solutions like solar inverter systems. Last but not least, rectifiers are crucial components of battery charging technology because they provide steady and safe DC outputs, essential for devices that consume significant power, such as electric cars, portable electronics, and backup power systems. Their versatility is proof of their might, as they play an important role in delivering power efficiently and maintaining stability across different sectors.

Converters in Industrial Applications

AC-to-DC Converters (Rectifiers)

AC-to-DC converters are used in the industry wherever there is a need for direct current. This includes electroplating, electrolysis, and the operation of electric motors. A good example is electroplating, where rectifiers provide an exact DC output that can be used to control the deposition of metals.

DC-to-AC Converters (Inverters)

DC-to-AC converters are essential for industries that rely on green energy sources. This is especially true in the case of solar farms and wind power generation. Somehow, they manage the large amount of DC power produced by photovoltaic cells and battery storage, delivering it as AC to the electrical grid and machines.

DC-to-DC Converters

These converters have a wide range of applications, including electric vehicles, telecommunication systems, and robotics. For example, in electric cars, DC-to-DC converters keep the voltage levels constantly under control between the batteries and other car systems, ensuring that everything works at its best.

AC-to-AC Converters

In industrial settings, AC-to-AC converters perform voltage transformation and frequency conversion functions. This is a must-have in industries that require variable speed and torque control for heavy machinery, such as textile production and metalworking.

Power Factor Correction (PFC) Converters

Industries make heavy use of PFC converters to boost energy efficiency and lower electricity bills. They are frequently used in the main supplies of manufacturing plants, which inflict a lower harmonic distortion on electric currents and thus comply with energy regulations.

Bidirectional Converters

Devices of this kind enable bidirectional energy flow, and this proves to be crucial in energy storage systems. They allow grids and battery storage systems to interchange energy, thereby making it possible to do peak shaving and load balancing in industrial operations.

Integration with Transformers

Transformers are a crucial part of the electrical energy system, especially when paired with advanced power electronics. The overall system becomes much more flexible and adaptable when transformers are integrated with rectifiers, inverters, and bidirectional converters. Voltage regulation, energy storage integration, and renewable energy systems like solar and wind power are some advantages of the system with transformers. In addition, modern systems employ smart transformers outfitted with IoT capabilities to offer instantaneous information about variations in load, performance metrics, and fault conditions. The combination of this integration leads to a considerable increase in energy efficiency, system reliability, and optimized resource usage in industrial and commercial applications.

Voltage and Current Considerations

It is fundamental to check the potential and current in power systems to prevent breakdowns or poor performance of the connected equipment. The supply voltage shall correspond to the specified values of the device, and the rated current capacity shall be adequate to ensure it does not exceed the security limits while supporting the expected future load. Devices that are well-organized and upgraded can indicate minor or seasonal fluctuations in voltage or current. It is essential to have the opportunity to correct any faults during these changes to maintain system stability and performance. Besides, proper insulation and earthing are the other two critical points for safety and the prevention of electrical dangers.

Impact on Voltage Regulation

It’s essential to have proper voltage regulation for the constant functioning and longevity of any electrical system. Inefficient regulation would lead to sags, spikes, and/or voltage variations that are very harmful to sensitive equipment. It can be safely stated that high-tech voltage regulators ensure consistent overall performance by moderating and stabilizing the voltage output under varying loads. One of the most illustrative examples is the quick response of modern automatic voltage regulators (AVRs) to voltage level conflicts, followed by correction before the system is affected. On top of that, recent studies indicate that enhanced regulation results in less energy consumption and thus an increase in bottom-line efficiency. Besides the reasons cited, one cannot help but mention another aspect involved: nature itself — the essential voltage regulation necessary to save the equipment and, most importantly, maintain the operations of the industrial, commercial, and residential sectors.

Current Flow in Rectifiers and Converters

In the realm of electric and electronic systems, rectifiers and converters are of prime importance; their primary job is the conversion of alternating current (AC) to direct current (DC) or the reverse. The current flow in the rectifiers consists of diodes that allow electrical current to pass in one direction only, thereby following the alternating wave and producing a constant DC output. In high-power applications, silicon-controlled rectifiers (SCRs) and insulated-gate bipolar transistors (IGBTs) are commonly combined in modern-day rectifiers to achieve higher efficiency and more precise control.

On the other hand, inverters are responsible for the bidirectional control of current and can perform both AC-DC and DC-AC conversion tasks. Along with advancements in semiconductor design, inverters have been able to operate with AC/DC and DC/AC at higher speeds, enhancing preparedness for renewable energy applications, electric vehicles, and industrial power supplies. Also, better management of heat and higher power density in the systems will extend their lifetime and reliability, so rectifiers and inverters remain essential in a contemporary energy structure.

Understanding the Power Factor

Power factor is an essential thing to consider when working with electric power systems. It may be simply described as the relationship between the real power, measured in watts, used to do work, and the apparent power, measured in volt-amperes, flowing in the circuit. A power factor almost equal to 1 denotes a highly effective system, where a significant portion of the power is put to good use. Low power factors, often resulting from inductive loads such as motors and transformers, can lead to energy losses and increased costs due to the burning of more fuel in power stations. However, using power factor correction techniques, such as capacitors or synchronous condensers, can make the system work more efficiently and help decrease the strain on the road and lower the electricity bill. Consequently, modern industries must pay attention to the power factor because it can be a very costly mistake if not addressed.

The Importance of Understanding Rectifiers and Converters

Rectifiers and converters are essential elements in electrical engineering because they transform power as needed for different applications. One everyday use for rectifiers is converting alternating current (AC) into direct current (DC), which is necessary for batteries, electronic equipment, and electric vehicles, all of which depend on DC power. However, converters can be seen as the ones who either work as the middlemen between AC and DC or change the levels of voltage and frequency as per the system’s needs. It is essential to have a better understanding of these devices, as they not only enhance energy efficiency but also improve the compatibility of different equipment and the smooth operation of electrical systems in both industrial and residential areas. If we know rectifiers and converters, we can be more active in system design and maintenance, ultimately achieving the reliability and good performance of the entire system.

Future Trends in Power Conversion Technologies

Power conversion technologies are evolving significantly, which is driven by renewable energy integration, energy efficiency, and sustainable solutions. The use of silicon carbide (SiC) and gallium nitride (GaN) for power converters is a key factor in improving efficiency, reducing switching time, and enhancing thermal performance. In addition, the implementation of energy storage systems, especially in the form of advanced batteries, is changing the way energy is distributed and managed, thus enabling a smooth connection of intermittent renewable energy sources such as solar and wind power.

Another major trend is the shift to more compact and modular designs, offering the benefits of more effortless scalability and adaptability across various applications. The power electronics sector is also witnessing changes brought about by new technologies, culminating in the creation of more intelligent systems that utilize artificial intelligence and machine learning for energy consumption optimization, as well as maintenance and downtime prediction. Therefore, power conversion technologies are expected to be a significant factor in meeting future energy challenges, aligning with the world’s efforts to shift to greener and more robust energy systems.

Final Thoughts on Electronics and Power Systems

The way technology is advancing very quickly, the electronic upgrade and power system modernization is already changing the industries and the way people live. The most current discoveries are focusing on the greener side of things and new green energy is being implemented through such means as wind and solar power. Data also indicates a significant global energy demand increase for the next half-century, necessitating very sophisticated systems with minimal energy loss. The power systems that will apply the real-time analytics and adaptive technologies are getting stronger, and they will be able to face the unpredictable challenges in a more efficient manner. These moves will not only give a cleaner earth but also enhance the economy through optimized resource management, making it the very base in the journey to a sustainable future.

Reference Sources

Al Sys Tech

Key Findings: This study explores a module design that integrates a rectifier, inverter, buck converter, and three-phase converter. The design is adaptable to various power requirements and input sources.

Input Switched Closed-Loop Single Phase SEPIC Controlled Rectifier with Improved Performances

Key Findings: This paper proposes a rectifier design with a SEPIC-controlled input switch, enhancing input current performance. The rectifier is paired with a DC-DC converter for improved efficiency.

Frequently Asked Questions (FAQs)

How does a rectifier circuit work?

The functioning of rectifier circuits entirely depends on semiconductors, a.k.a. solid-state rectifier diodes or whatever other type of diodes. The conversion of electrical energy is what semiconductor devices do when switching AC to DC, and this process can be applied to different existing machines. Among many others, the half-wave rectifier and the full-wave rectifier circuit are two very well-known and widely used rectifier circuits. The issue with the half-wave rectifier is that it allows only one half—positive or negative—of the AC waveform to pass through, which eventually causes the DC output to fluctuate slowly. Meanwhile, the full-wave bridge rectifier, which requires not only a number of diodes but also spans the entire cycle of the input power, provides a much cleaner DC signal.

What is the role of a transformer in relation to rectifiers?

A transformer is usually employed together with rectifiers to modify the voltage levels before rectification. It changes the AC voltage coming from the power mains to another voltage level that is perfectly suitable for the specific application. For instance, a center-tapped transformer can produce more than one voltage output, which can later be treated with a full-wave rectifier circuit. The transformer allows the rectifier to receive the proper AC signal, which is crucial for obtaining the desired DC output. Thus, the transformers in this manner contribute significantly to the total efficiency of the rectifier systems.