Determining the speed of a single-phase AC motor is crucial these days because it influences almost everything from small home appliances to giant industrial machines. Being aware that motor controllers will let you save energy, make operations more precise, or help you extend your equipment’s life, is a must. This article is going to take you through the process of controlling the speed of a single-phase AC motor’s world, constituting the interpretation of the concepts, tools, and techniques needed As a matter of forwarding pointer, the readers will soon find out how motor speed controllers work, where they can be applied, and the pros that they bestow to the different systems. You are welcome to explore with us the exposure of the scientific and practical sides of enhancing motor performance by means of optimization!

Introduction to Single-Phase AC Motors

Single-phase AC motors have a widespread application, mainly characterized by their simplicity and efficiency wherever they are used. They are compatible with single-phase power, making them a perfect fit for locations without three-phase power. They are usually seen in the case of fans, pumps, compressors, and even household appliances. The design includes a stator and a rotor, with the rotor being driven by the stator to create a rotating magnetic field. Considering their start-up power consumption, these motors are generally considered extremely fuel-efficient. However, they are the next-to-lowest in starting torque compared to three-phase motors, which may sometimes require additional mechanical means, such as beginning capacitors, to be employed.

Overview of Single-Phase AC Motors

Single-phase AC motors are extremely popular, mainly in applications where there is a need for a dependable and cost-efficient energy source for low to moderate power requirements. Their primary benefit is their compatibility with the house’s power supplies, which eases motor selection for both living and working environments. The basic applications of these machines are household appliances such as washing machines, refrigerators, and air conditioners. Besides, they could be found in little industrial equipment, office machines, and portable industrial tools like drills or saws. These motors should be considered in terms of design because they are well-liked, strong, and easy to maintain. They indeed have less starting torque than three-phase motors, but the technology has found a solution using capacitors to achieve the same level of torque. The current progress in motor technology is focused on achieving higher energy efficiency and reducing noise, making single-phase AC motors an essential component of power systems for the years to come.

Applications of Single-Phase AC Motors

Household Appliances

The single-phase AC motors are extensively used in everyday household devices such as fans, refrigerators, washing machines, and air conditioners. One example where you can find these motors is in ceiling fans, which typically use capacitor-start motors with power ratings as low as 60 watts and a good coefficient of performance. Again, like refrigerator compressors, those that require a lot of pulling force on startup also utilize single-phase motors.

Small-Scale Industrial Equipment

In workshops, these motors are employed at the rear end of small tools and machinery such as drills, saws, and lathes. For such use, single-phase motors are the best solution as they provide enough power for light-duty applications with power requirements of up to around five horsepower (HP).

Pumps

In the case of domestic and agricultural water pump installations, the majority of them are driven by a single-phase motor. The rating range of such motors under these conditions is from 1 HP to 3 HP. Therefore, they are typically used in large livestock and irrigation machinery due to the motor’s controllable and continuous power output.

Office Equipment

The reason photocopies, small HVACs, and even shredding devices typically run on single-phase AC motors is that they consume power in a demanding, reliable, and compact manner.

HVAC Systems

Commonly found single-phase motors are also applied in HVAC, specifically in the systems of small buildings and residential complexes. Also, their power is relatively small, ranging from 0.25 HP to 1 HP, depending on the requirements of the system.

Compressors and Blowers

Single-phase AC motors are the best choice for low-capacity air compressors and blowers. They are the ones that provide the same amount of air efficiently and are easy to maintain. The machine, with air consisting of a double stroke, is the best for the application.

Benefits of Single-Phase AC Motors

✓ Simplicity and Cost-Effectiveness

Because of the simple design of single-phase AC motors, they are easier to build and repair, hence cheaper. This departure from the expense side is especially essential for applications where money is a scarce resource but reliability is critical.

✓ Ease of Maintenance

One of the best aspects of single-phase AC motors is their thorough design, which allows greater access to the components, making the whole unit very easy to maintain and service. This feature is exceptionally advantageous in manufacturing, where stopping operational activity for maintenance is not profitable.

✓ Availability and Compatibility

Single-phase AC power supply is almost everywhere in residential and commercial areas, hence single-phase AC motors are perfect for these places where three-phase power is not available or viable. They can operate seamlessly without needing to connect any extra equipment to the standard electrical systems.

✓ Energy Efficiency for Small Loads

In the case of small loads, single-phase AC motors tend to be energy-efficient alternatives. They are designed to be efficient in terms of energy consumption, which not only reduces operational costs but also contributes to the Earth’s “Save the Earth” campaign.

✓ High Reliability for Low-Demand Tasks

These motors work well for low-demand devices where mechanical stress is not an issue and are widely regarded for their superior durability, which ensures long life spans when used under correct operating conditions.

Understanding Motor Speed Control

To manage the speed of its rotation, the motor is controlled to meet the application’s requirements. The use of variable frequency drives (VFDs) is predominant for AC motors, and this change leads to an alteration in the frequency and voltage that is provided to the motor. VFDs are popularly adopted in the industry as a result of their effectiveness and exactness. For clear-cut operations, other methods such as changing the input voltage and using mechanical gear systems may be applied. But the real benefit comes when the motor speed control is proper, which leads to increased energy efficiency, better performance, and longer life for all motor-driven systems. Knowing in great detail what is really required from the application is essential for selecting the best control method.

The Importance of Speed Control in AC Motors

Motor speed control technology has progressed recently, which has eventually led to the AC motors becoming much more efficient and performing better. The application of innovative technologies, such as IoT-controlled Variable Frequency Drives connected to the internet, allows the system to be constantly monitored, ensuring the motors are always kept in perfect condition through precise adjustments. Besides, the systems in this case, by dynamically matching motor speed with actual load, can save significant energy, thus significantly reducing the cost of operation. Furthermore, there is ongoing progress in the sphere of predictive maintenance, where early detection of potential problems is made through speed control technologies. Thus, the equipment is not left inactive for long periods, which prolongs its life. Many sectors, like manufacturing, HVAC, and renewable energy, are now heavily investing in these technologies to make their investments both profitable and environmentally friendly.

Key Components of a Motor Speed Controller

| Key Component | Description |

|---|---|

| Microcontroller Unit | The central processor manages speed regulation and control. |

| Power Supply | Provides the required voltage and current to the controller. |

| Input/Output Interface | Connects external sensors, switches, or control inputs. |

| Pulse Width Modulation | Regulates motor power by adjusting voltage and frequency. |

| Current Sensor | Monitors electricity to prevent overcurrent damage. |

| Cooling System | Prevents overheating during prolonged operations. |

| Feedback Loop | Collects data to ensure consistent motor performance. |

| Safety Features | Protects the system against short circuits and overloads. |

| Control Panel | User interface for setting operating parameters. |

| Communication Module | This system enables external data exchange through protocols like CAN and RS-485. |

Types of Motor Speed Control Methods

| Control Method | Description | Key Parameters |

|---|---|---|

| Voltage Control | The system controls speed by varying the motor supply voltage. | Voltage, Load, Efficiency |

| Resistance Control | Adjusts external resistance in motor circuits. | Resistance, Heat Loss |

| Frequency Control | Alters motor speed by changing supply frequency. | Frequency, Torque Stability |

| Pulse Width Modulation (PWM) | Regulates speed via the duty cycle of the signal. | PWM Duty Cycle, Power Loss |

| Field Control | Adjusts the magnetic field of the motor. | Current, Magnetic Flux |

| Vector Control | Controls speed by decomposing motor current. | Torque, Current Phase |

| Direct Torque Control (DTC) | Directly manages torque and flux levels. | Torque, Flux Accuracy |

| Closed-loop Control | Uses feedback for precise speed regulation. | Sensors, Controllers |

| Open-loop Control | Operates without feedback for simplicity. | Input Signal, Load Type |

Electronic Speed Control Methods

When it comes to motor operations, the Electronic Speed Control methods play a very crucial role. They deliver not only precision but also efficiency and adaptability. The modern mechanic can expect much more when he turns to these methods. To begin with, let us first examine how the speed of the motor can be adjusted and what the best performance under a load demand will be. It also refers to the efficiency upgrading power, which then results in low power losses and less wear. Among some of the other benefits of using this technology is the ability to control using different methods, like closed-loop for precision and open-loop for simplicity. This will mean flexibility, allowing one to get other solutions that meet the needs of industrial and commercial sectors. The advantage is that the systems can still operate without any hurdles, meeting the pre-set personal performance requirements.

Variable Frequency Drives (VFDs)

In the context of industries, you have the advantage of using Variable Frequency Drives (VFDs), which offer a broad scope of benefits that cannot be overestimated, making them an inseparable part of any motor-driven system today. One of the most attractive features of VFDs is the ability to cut the energy usage by a large percentage, as they make motors to run at the speeds required by the process rather than them keeping their full capacity load all the time. It has been well-established by research that the use of VFDs in motors can take the power consumption down by 50%, which can be translated into considerable cost savings and, at the same time, the environment can be benefited.

Moreover, VFDs enhance system reliability by reducing the force exerted on a motor during startup and gradually increasing speed instead of applying an instant shock to the system. This, in turn, lowers maintenance and repair costs and increases the life expectancy of the equipment. Their use is widespread, reaching the HVAC sector, water treatment plants, and production facilities, among others. The properties of the technology determine the inclusion of VFDs in these sectors. The most recent IoT characteristics and predictive maintenance capabilities are examples that have been integrated to increase the efficiency and attractiveness of industrial and commercial applications.

Pulse Width Modulation (PWM) Techniques

Pulse Width Modulation (PWM) is a significant method used in VFDs to control two of the most critical parameters of an electric motor: voltage and frequency. With PWM, a non-constant wave is generated by turning the power supply on and off quickly at different time intervals. This technique also limits power loss, making the motor more efficient when it is running. The PWM method can take the full credit for its power loss reduction feature, i.e., some energy is lost while the motor is running. Modern PWM control techniques have advanced to include intelligent algorithms for removing harmonic distortion, thereby making the system more stable than before. These advancements have found their applications mainly in the sectors of robot operation, transportation systems like conveyors, and manufacturing with very close tolerances. The research on PWM technologies is maintaining momentum to bring more efficient, reliable, and adaptive solutions for the ever-rising needs of the vast industrial and commercial sectors.

Microcontroller-Based Speed Controllers

Speed controllers based on microcontrollers have, in fact, become essential in modern motor control systems by providing high-performance regulation in an accurate and energy-efficient manner. There is the power to achieve excellent speed control through the microcontroller and advanced programming capabilities, while also enhancing performance tailored for specific applications. Microprocessors, with their real-time processing feature, will be able to adapt to any changing condition and will operate smoothly, minimizing energy consumption as well. Industrial applications where automatic control is essential are examples where microcontroller-based controllers excel at maintaining a specific speed and torque, even when different loads are applied.

The latest developments in this field primarily aim to improve data acquisition and communication features. Nowadays, most microcontrollers can work with advanced communication protocols like CAN, UART, and SPI, making it possible to introduce embedded solutions as a significant part of the interaction in various systems. Even though it is possible to see the progression of industry IoT and 4.0 the most in smart manufacturing and predictive maintenance, more and more applications in the industrial automation field are starting to be covered by high-performance microcontrollers with increased memory and processing power available to them, giving them more precise and energy-efficient control on a whole industry scale.

Mechanical Speed Control Methods

Mechanical speed control methods are techniques used to regulate the operational speed of machines or motors through mechanical means, without relying on electronic control systems. Common methods include:

- Belt and Pulley Systems: The speed of machinery connected to the AC motors can be effectively adjusted by changing the diameter of the pulleys or moving the belt to different grooves.

- Gear Mechanisms: For example, changing gear ratios allows for precise speed control in vehicles or industrial equipment.

- Clutches and Brakes: These may provide partial speed control or minor adjustments by intermittently handling torque transmission within the system.

These somewhat outdated mechanical skills are not only beneficial in environments where electronic control systems might not be available, but also due to their cost-effectiveness.

Gearbox and Pulley Systems

Gearbox and pulley systems are basic units in mechanical engineering designed to transfer torque and speed more efficiently within machinery. During operation, the varying numbers of teeth alter the gear ratios of the motor’s input and output, enabling the operator to achieve the desired performance. Pulleys, on the other hand, carry this process further by using belts to transfer the rotating movement from the source of power to the rotating member, resulting in an increase in speed, a direction change, and a variation in torque.

These systems, when combined, are highly adaptable across various industries. By way of illustration, one very typical example is the case of pulley systems working with gearboxes in conveyor belts to ensure that the movement remains smooth and at the desired speed. In a parallel manner, this particular combination is used in large machines that need to produce sufficient power while maintaining speed in a controlled manner for precise operation. Moreover, material and manufacturing/production technologies are significant factors that have enabled innovation in efficiency, uptime, and energy. That development not only increased the durability and energy savings but also made the systems irreplaceable tools of the day-to-day production work of the modern era.

Variable Resistors and Rheostats

Variable resistors and rheostats are of key importance in managing electric currents by providing adjustable resistance within circuits. A variable resistor, which is regularly a part of such devices as volume controls or light dimmers, functions precisely, enabling the user to control output levels with extreme accuracy. Rheostats, a subset of variable resistors, are typically used in applications that require higher power handling, such as motor speed control or heating elements in industrial systems.

The latest trends in the field indicate that cross-linked resistive materials with improved mechanical and thermal properties include carbon and metal oxide. Apart from this, the new designs are constructed with the latest technologies, making them smaller in size while still having the capability of high power ratings for advanced applications, ranging from renewable energy systems to complex electronics. All these will be very important and will underpin the progress of technological and industrial aspects by providing power across the entire current regulatory spectrum.

Switching Mechanisms for Speed Adjustment

Mechanisms that switch play an essential role in accurately adjusting speeds in modern and more complex systems, especially in cases of electric motors and fans. The application of contemporary processes, such as PWM (Pulse Width Modulation), enhances control efficiency by adjusting the duty cycle of the electric signals, thereby regulating the motor’s speed with minimal energy loss. Continuous modulation of energy power is the most common way to control speed in VFDs (Variable Frequency Drives) in industry, and it is also an effective method in nature to achieve this in a very energy-efficient way. These two methods are essential for improving performance, saving energy, reducing maintenance, and ultimately being cost-effective in industries that heavily rely on energy applications.

Challenges in AC Motor Speed Control

There are several challenges to controlling the speed of AC motors effectively. One major issue is the stable operation of the motor when the load varies constantly. Load variations can lead to speed oscillations, thus requiring advanced control systems to ensure that the operation is continuous. Additionally, the increased risk of inefficiency is another issue, as incorrect regulation of the speed may cause the motor to consume more power than necessary. Furthermore, the expenses and complexities of providing VFD control systems that precisely regulate speed can be burdensome, especially for small-scale operations. Finally, ensuring the motor has the best lifecycle possible, while frequently adjusting its speed, involves balancing performance and wear possibilities, highlighting the importance of robust and reliable control methods.

Common Issues Faced in Speed Regulation

A speed regulation problem that is commonly encountered is maintaining stability under varying load conditions. The motors are exposed to the altered load during their working time. If they are allowed to remain unperturbed, the variations can cause the system to operate below the expected speed, thereby upending the overall system performance. Additionally, electromagnetic interference (EMI) from other equipment in industrial or commercial areas is not always easy to eliminate. This interference blocks or distorts the signals, which is usually the job of the motor control system, making precise control difficult. Moreover, suppose there is a change in speed. In that case, the motor heat issue becomes more pronounced, as different speeds can be uncomfortable and may lead to overheating or damage if not properly managed. Solving these issues is only likely if advanced monitoring systems and adaptive algorithms are integrated, ensuring control and monitoring solutions, as well as the efficient operation of the motor appliances.

Troubleshooting Tips for Motor Speed Controllers

1. Check Power Supply Stability

Make sure the power supply provides the same voltage and current all the time. The power source’s perturbations can cause the motor to operate at irregular speeds or make the controller fail. To detect the voltage, use a multimeter and compare it with the controller’s specifications.

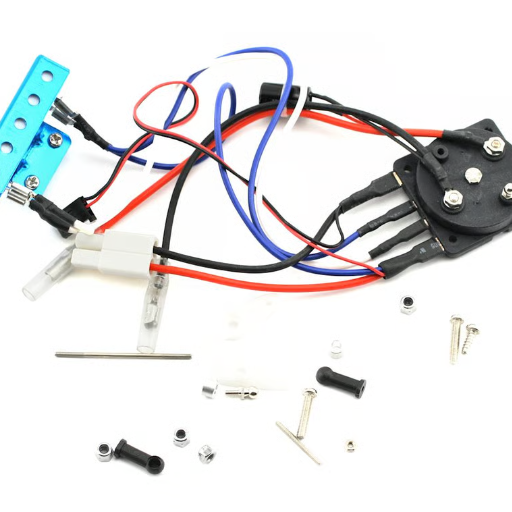

2. Inspect Connections and Wiring

Use of defective or detached cables is another issue that causes interference between the controller and the motor. Keep checking all the wires and the tightness of the connections every time to avoid problems. In case the cables are faulty, swap them out and ensure the connections are securely attached.

3. Verify Controller Settings

Performance issues may be caused by programming or settings given inaccurately. It is recommended to frequently review control settings associated with the automatic controller, such as acceleration time, deceleration time, and maximum speed limits, to meet the motor’s requirements perfectly.

4. Monitor for Overheating

Too much heat can harm the motor as well as the controller. Your best bet is to take pictures with a thermal camera or use a temperature sensor to monitor the overheating that may occur during operation. In any case of overheating, you will have to let the air pass or make your cooling system more effective, e.g., by fusing fans or heat sinks.

5. Examine Load Conditions

There is a possibility that a motor could be legally used without a controller, but this could negatively affect the operation or cause frequent shutdowns. Thus, the driver is advised to monitor the motor’s loading from a mechanical perspective to ensure that the load does not exceed the capacity. If the motor is overloaded, the weight should be redistributed or the load should be lightened accordingly.

6. Check Signal Integrity

For control systems that are either digital or have analog signal linking, it is essential to ensure that the signals are within the normal range and are clean. The motor can act erratically if there is a noise in the signal. Leading the cables away from electromagnetic interference (EMI) and using the correct grounding methods are necessary steps.

Impact of Load Variations on Speed Control

Variation in the load can have a substantial effect on the performance and the reliability of the speed control systems in the motors. When the load on the motor suddenly increases, it must be unhesitatingly controlled by the current and power draw, maintaining stability at the same speed through the means mentioned above. Otherwise, it can overheat or even wear out if the system cannot handle such a situation. In contrast, a swift change in the load may occur due to speed, as they might be far below the target value, leading to severe non-linear performance that could disrupt the ongoing operation.

It is necessary to have properly calibrated feedback loops in the speed controller, such as a PID controller, to deal with those variations. Such systems can adapt motor parameters according to the varying conditions to get the best performance. The use of vector control and other technologies has facilitated better motor reaction by providing precise torque and speed control, even when the load is being shifted. Consequently, the system can stabilize and maintain efficiency if the operational conditions change.

Reference Sources

A Review on Speed Control Techniques of Single Phase Induction Motor

Summary: This paper provides a comprehensive review of various speed control methods for single-phase induction motors. It categorizes techniques into mechanical, electrical, and electronic methods, highlighting their advantages and limitations.

Speed Control of Single Phase Induction Motor Using AC Chopper

Summary: This research explores the use of an AC chopper with an asymmetrical PWM technique to control the speed of single-phase induction motors. The study demonstrates how this method reduces harmonic distortion and improves motor performance.

Frequently Asked Questions (FAQs)

How do variable frequency drives (VFDs) affect motor speed control?

Variable frequency drives (VFDs), by adjusting frequency, are crucial for the speed control of AC motors, allowing for dynamic and quick changes in speed or power output during operation. The usage of VFDs, as an example, makes it possible to lower the speed of a motor below 50 Hz without the need for special-ordered motors. In this case, the application of VFDs is most advantageous as it also creates energy savings and other beneficial effects. In a system with VFDs, higher-than-normal line voltage is quite usual. If this is the case, it may seriously affect a motor’s life expectancy.

What is the importance of input frequency in single-phase motor control?

The input frequency is the most significant factor in setting the speed of a single-phase motor. Suppose, for example, a motor that is to be driven by 60Hz will typically run at a fixed speed, but if the input frequency is tampered with, for example, decreasing it to 50Hz, the speed of the motor will also reduce. Being knowledgeable about the regulation of frequency is useful, and it is possible to achieve the required speed for an application. On the other hand, a frequency converter can be an alternative aiding device in this matter, contributing to the optimal performance of the motor. Therefore, the motor control becomes more efficient once the right frequency set is achieved.

What are standard methods for controlling the speed of a single-phase electric motor?

There are several ways to manipulate the rotation speed of single-phase electric motors. Using variable frequency drives, resistors, and capacitors is one of the most popular methods. VFDs are the best because they can finely tune the input frequency, and therefore, the speed of the motor. Another technique is regulating the speed of the motor by changing the resistance via a potentiometer, which adjusts the speed parameter but may impact power utilization. Besides, rotary switches and motor governors are devices that offer fixed speed settings for various uses. Every way has its pros and cons, and hence, the decision relies on what is required in each case.

How does the power supply affect single-phase AC motor speed control?

Single-phase AC motors’ control and performance are highly dependent on the quality of the power supply. Any shifts in voltage and frequency can easily cause the motor to lose uniformity in terms of the speed and torque it develops. A dependable power source is a requirement for the motor to operate safely and efficiently. Still, the opposite can be true for power sources with significant variations in voltage and frequency. The use of a well-sized VFD can mitigate that fluctuation, making the power supply more stable and other processes, such as speeds and load, better manageable. Furthermore, understanding the power supply and motor system characteristics is necessary to ensure long-lasting motor life and prevent downtime in various applications.