Electric motors are every engineer’s favorite choice for power conversion and control. In such technology, single-phase-shell induction motors are probably the most compact, efficient, and durable, even when compared across industries and fields. Nevertheless, that flaw did not block them from being so widely used and loved. Moreover, the primary fault lies in the speed-control capability of such machines. It cannot be pointed out ideally as a fault, but rather as a less developed control performance and options. Despite the latter, run another test to identify the fault causing the induction motors to go out of speed, and compare it with a test of motors without external speed control devices.

Introduction to Single-Phase Induction Motors

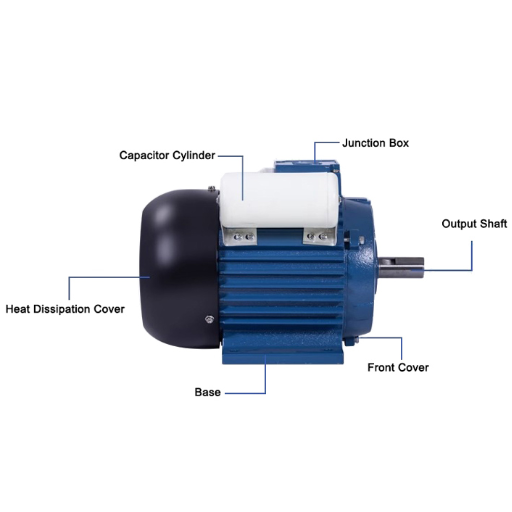

Single-phase induction motors are used in many applications and are chosen primarily for their simplicity, reliability, and lower cost. They get their power from the single-phase electric distribution system. They are seen in home appliances, fans, pumps, and small equipment, among other things. They mainly consist of a stator, which generates a rotating magnetic field, and a rotor, which receives this field and thus produces torque. Even though single-phase motors are ideal for low-duty-cycle applications, their lower power output and efficiency compared to three-phase motors are significant drawbacks. Single-phase induction motors are the choice for many because of their simpler design and easier maintenance in daily applications.

What is a Single-Phase Induction Motor?

Single-phase induction motors have a strong side: they are always the number one choice in many sectors. Because of their straightforward structure, they can be built quickly and at low cost, making them an economical option for home and small-industry applications. They are efficient for being compact, light, and plug and play, and very often they are used without noticing. Another point is the trustworthiness and low demand for maintenance, which rate them as the best option for anything that is meant to be used for a long time. With all those three characteristics, low cost, simple operation, and long service life, single-phase induction motors are unreplaceable and will always be needed in tasks that require low to medium power.

Basic Principles of AC Motors

AC motors are machines that function through the use of electromagnetic induction and thus transforming electrical power into the potential to work in a mechanical unit. These motors require an alternating current to initiate a magnetic field rotation within the stator and activate current in the rotor, which makes it rotate. The main two categories of AC motors are synchronous and asynchronous (induction) motors. Synchronous motors are having a rotor that spins at the same frequency as the stator’s magnetic field, while the induction motors, on the other hand, generate a slight slip in their speed and induce current into the rotor. Improvements in materials and design have boosted the efficiency and productivity of AC motors thus making them the main components in the industrial world by making them a part of various applications such as heating, ventilation, and air conditioning (HVAC) systems, conveyors, and robotics. The versatile, energy-saving, and load-adaptable nature of these motors guarantees their continuous support as a vital unit in the automation of diverse mechanical and electrical systems.

Applications of Single-Phase Motors

Household Appliances

Single-phase motors are usually seen in household items, like refrigerators, laundry machines, air conditioners, and fans. They are designed to have a reliable and power-efficient operation that would fit well with the lesser power needs of the domestic equipment.

Small Industrial Machinery

These motors can operate small lathes, drills, and light-duty industrial machines. Although they are little in size, the price is within the reach of small enterprises, and the maintenance work is non-time-consuming leading them to be the best choice for small-scale businesses.

Pumps

Single-phase motors are employed to provide the power for water pumps installed in living areas, gardens, and light agriculture plots as well. Water pumps, especially centrifugal pumps and submersible pumps, are common appliances using these motors all over the world because they can operate more effectively with lesser power input.

Compressors

Air compressors are another typical application where single-phase motors are used. The garage, small workshop and other working areas with commercial air compressor needs are usually equipped with this, to generate the power pressure that will be beneficial to various pneumatic tools.

HVAC Systems

The use of single-phase motors for the motors that were supposed to be used for driving blowers and fans in heating, ventilation, and air conditioning systems, particularly those designed for small to medium-sized spaces, is very common.

Office Equipment

Use of single-phase motors is prevalent for devices like photocopiers, paper shredders, and binding machines. These applications take advantage of the motors’ low maintenance and small size.

Speed Control Methods for Single-Phase Induction Motors

- Voltage Control: The motor’s speed is directly influenced by the rate at which the voltage is adjusted. It’s a simple yet most successful method for applications that require minimal speed adjustment.

- Frequency Control: By varying the frequency of their power supply, the motor’s speed is effectively adjusted. It is a precise, widely used approach for variable-frequency drives (VFDs).

- Pole Changing: Some motors are designed with multiple pole configurations. Altering the number of poles can thus change the motor’s synchronous speed.

- Capacitor Adjustment: The capacitance in capacitor-start or capacitor-run circuits, when modified, can affect the motor’s performance and speed under specific conditions.

Overview of Motor Speed Control

Electric motor speed regulation is an essential factor in power applications across industries, affecting performance, precision, and energy efficiency. Major industrial processes, namely manufacturing, heating, ventilating, and air conditioning (HVAC), and robots, need to have the ability to increase or modify their speed. This is made possible by Variable Frequency Drives (VFDs). There are numerous ways VFDs can support, starting with allowing machines to run at their designed speed and preventing the energy waste that results from any deviation.

For the same reason, the latest technology is being used for these machines at different stages. For example, VFDs can allow units to operate at speeds far below their rating, which may lead to bearing damage and, eventually, wear out, saving power that would otherwise be wasted. Besides, sensors can now respond instantaneously to the motor’s power; thus, very little time is needed to tune them.

Common Ways to Control the Speed of a Single-Phase Motor

| Method | Key Points |

|---|---|

| Voltage Control | Adjusts speed via voltage regulation. |

| Frequency Control | Alters motor speed by changing power frequency. |

| Resistance Control | Inserts resistance to control current and speed. |

| Capacitor Control | Uses capacitors to tweak motor performance and speed. |

| TRIAC Control | Employs TRIACs for adjustable voltage and speed modulation. |

| Pulse Width Modulation | Varies motor speed by controlling the duty cycle of power. |

| Multi-tap Transformer | Changes motor speed using different tap voltage levels. |

| Phase Angle Control | Modifies the phase angle of supply voltage to adjust speed. |

| Soft Starters | Gradual power increase controls initial speed and operation. |

Variable Frequency Drives (VFDs) and Their Role in Speed Control

The precise motor speed control approach using Variable Frequency Drives (VFDs) allows the motor speed to be varied to suit the requirements of a given application. These drives work by adjusting the frequency and voltage supplied to the motor, thereby saving energy and improving system performance during load changes. More than that, VFDs also allow for controlled, smooth speed increases or decreases, which ultimately reduce the risk of equipment failure and extend equipment life expectancy. Last but not least, through them, the processes are better controlled, which, in turn, makes the whole system more productive and reliable.

Understanding Variable Frequency Drives

Variable Frequency Drives (VFDs) are equipped with a few essential components that work together to control the speed of an electric motor. The main components include the rectifier, DC bus, and inverter. The rectifier converts the incoming AC power to DC power, which is then flattened and stored on the DC bus. The inverter, with the help of power electronics, can then convert DC power back to AC power at the required frequency and voltage to operate the motor.

In addition to the advanced features, such as built-in microprocessors and software for motor control, monitoring, and diagnostics, other technical features are driving these drives’ growing use across all industries. They are used in a variety of applications, including HVAC systems, conveyor belts, pumps, and industrial machinery. The use of innovative technologies in VFDs helps save energy, provides valuable insights into system operations and remote diagnostics, and reduces overall system energy consumption.

How VFDs Control the Speed of Single-Phase Induction Motors

The speed of single-phase induction motors is regulated by oscillation and power methods supplied by Variable Frequency Drives (VFDs). An induction motor’s speed is calculated based on the equation Ns = 120f / P, where Ns represents the synchronous rotation speed in revolutions per minute (RPM), f is the supply frequency in Hertz, and P is the number of poles of the motor. VFDs, by varying frequency (f), effectively change the synchronous speed, providing precise speed control.

Typically, the motor needs to be specially modified or designed to adapt to variable frequencies, should the user desire to use a VFD with a single-phase motor. VFDs are available with features that support single-phase motors through specialized circuitry or configurations such as capacitor switching. Moreover, the VFDs of today are designed with control systems based on microprocessors, therefore, providing the operational means for such functionalities as dynamic guessing of torque, soft starts, and economical energy usage. VFDs thus perform very effectively in terms of performance, wear reduction, and energy savings.

Advantages of Using VFDs for Speed Control

Energy Efficiency

It is the VFDs that are responsible for the enormous reduction in energy consumption, as the motors operate at the most efficient speeds for the given tasks. The numbers suggest that installing a VFD in the HVAC system or a pump, among others, can lead to as much as a 50% reduction in energy consumption and, eventually, substantial cost savings.

Soft Start and Stop

VFDs provide shockless increments, programmed for instantaneous motor run. VFDs provide soft start and stop, which saves mechanical drive elements like belts, gears, and shafts from excessive stress and thus prolongs the life of the equipment.

Precise Speed Control

The process runs at different speeds, but VFDs can precisely set the motor speed to meet the process requirements. This capacity is incredibly beneficial, especially in systems that use conveyor belts, as preventing inconsistencies in the final product is a priority.

Reduced Maintenance Costs

The time the motor is running, in addition to the motor output, is always kept at a level that does not put it under a lot of stress or cause damage. Thus, VFDs can not only drive systems at lower speeds properly without the need for a large motor but also extend the motor’s service life.

Improved System Performance

Dynamic loads are much easier to control when using VFDs. The machines that use the motor’s constant output and are rarely shut down, such as extrusion, centrifugal pumps, and industrial fans, are the ones that usually benefit most from VFDs.

Power Factor Improvement

The enhanced design of current VFDs improves the overall power factor of electrical systems. This exerts more need for fees on electric bills and improves the power quality of the grid.

Challenges in Speed Control of Single-Phase Induction Motors

Single-phase induction motors are made to run at a constant speed, which is generally determined by the motor’s design in relation to the supply frequency and the number of its poles. In comparison, their three-phase counterparts have the chance to obtain variable speed more readily, of course, with corresponding assistance of torque in the same way as in the three-phase case. However, no doubt it is their beauty that made these two very different sides exist. With the possibility of gear adjustment, the same electric motor can keep running for anyone under standard conditions. Another major problem with these drives is the power loss caused by unnecessary power dissipation, in addition to the initial high costs. The motor winding may succumb to the increased ambient temperature it was not initially intended for, or to several other reasons, worsening its heat insulation performance —sometimes the only way to diagnose these hard-to-find root causes/universal motor problems, or destroying the motor. The motor cooling process/heat dissipation generally deteriorates significantly at lower speeds, and this time, it’s an efficiency loss due to unnecessary power dissipation.

Common Issues Faced during Speed Control

A significant difficulty in controlling the steady-state performance of single-phase induction motors is maintaining torque stability. At low rotation speeds, motor shaft load can drop considerably, leading to a significant reduction in power regardless of the gearing between the motor and the load. This also results in a decline in motor braking and low torque during operation. This makes the motor ineffective for applications needing constant power output. On the other hand, another issue is the high energy demand at reduced speed when using methods such as V/f control, because such methods might have adverse effects, such as poor power factor and increased heat. Besides that, electronic devices can cause electromagnetic interference (EMI) that could harm existing equipment or communication systems. The above drawbacks clearly indicate the need for a thorough understanding of the load and system requirements. Moreover, applying appropriate control technologies to the motor can improve performance and reliability.

Solutions to Overcome Challenges

In response to issues arising from motor control techniques, there are multiple ways to expand the possibilities and reduce problems through the implementation of several solutions. The first point worth mentioning is the application of variable frequency drives (VFDs), which are highly advanced motor control systems that can speed up machine operation while accurately controlling the motor’s power. In addition, introducing electromagnetic interference (EMI) filters is one of the most effective methods for better regulating nearby electronic circuits, thus preventing signals from being interfered with.

System design and maintenance are other important factors. A technical solution perfectly matched to the control technology will prevent energy and labor losses and extend the system’s lifespan. From the use of the best materials to routine maintenance, all these processes will improve the system’s performance. The last step is to adopt Industry 4.0 technologies and integrate the IoT monitoring system. Through these, the system can be checked online, thereby reducing costs and operational time. All these innovative steps, taken together, address the problems and raise the system’s performance to the highest level.

Future Trends in Single-Phase Induction Motor Speed Control

The future of single-phase induction motor speed control emphasizes energy efficiency, advanced control methods, and innovative technologies. One of the most promising trends is the single-phase motor-specific VFD-based and the precise-speed-control-reduction-of-energy-consumption approach. Moreover, the increased use of sensor-based technologies for real-time monitoring and feedback is already underway, which will improve performance and reduce maintenance needs. Machine learning and artificial intelligence are being introduced into motor model optimization and risk prediction to predict motor failures and prevent them before they occur. The main goal of these technological innovations is to transform single-phase induction motors into more efficient, reliable, and responsive machines to meet the requirements of future energy and automation fields.

Emerging Technologies in Motor Speed Control

There has been remarkable progress in the field of motor speed control, as evidenced by the technology itself. Especially, running Variable Frequency Drives (VFDs) is one of the top innovations that enable precise control of motor speed and torque in real time. Integrated with smart sensors, the present VFDs employ advanced algorithms to adapt to load variations; consequently, they reduce energy consumption and the wear on motor components. Besides, sensorless vector control has lately been a favorable option, as it enables more accurate control of speed and torque without additional physical sensors, thereby simplifying system design and reducing costs.

The use of field-oriented control (FOC) and other innovative methods is the main reason for the latest progress in motor technology—they enable the use of sophisticated mathematical models to adjust the motor currents in just the right way, thus making the motor operate smoothly even during rapid speed changes. On the other hand, advancements in wireless communication have provided a reliable way to control motors from a remote location, thereby increasing the motors’ operational flexibility in both industrial and residential sectors.

Integration with Smart Systems

The combined use of innovative technologies and motor speed control systems has led to a complete transformation of operational tactics in industries and homes. Present-day sensors and IoT-connected devices can now perform real-time analysis and data sharing, thereby enabling predictive maintenance and reducing downtime. Such systems easily connect to cloud-based platforms and, therefore, allow users to monitor performance and, at the same time, optimize energy costs very efficiently. Moreover, implementing AI in the process will enable the use of optimized algorithms and thereby communicate the precise adjustments that can be made across the entire system. The cooperation of innovative technologies and motor control systems is providing not only innovation but also technologically advanced, environmentally friendly applications.

Sustainability and Energy Efficiency Considerations

Modern motor control systems play a significant role in the sustainability plan by reducing energy waste and mitigating environmental impacts. When VFDs and advanced energy management tools are used, the result is precise control of motor speed and power requirements, thereby lowering overall energy needs. As noted by the same industry research, VFD utilization in systems can achieve energy savings of up to 30% compared to fixed-speed motors in a classical system. Further, when sources of renewable energy, like sunlight and wind, are integrated into the system, their scale becomes more visible toward the sustainable side, as they will already be part of the process. So, businesses and sectors that adopt eco-friendly innovations are, in the long run, agreeing to adopt eco-friendly operations, thereby cutting their operational costs and playing their part in the future scenario where clean and efficient energy solutions will be used.

Reference Sources

Experimental investigation of conducted electromagnetic interference in speed control of single-phase induction motor

Key Findings: This study explores the use of TRIAC and Bluetooth devices for speed control of single-phase induction motors. It highlights the effectiveness of combining traditional power electronics with modern wireless communication for enhanced control and reduced electromagnetic interference.

Study performance of single-phase induction motor three-speed control

Key Findings: This research provides an in-depth analysis of the performance of single-phase induction motors with multi-speed control. It emphasizes the importance of accurate performance analysis for optimizing motor efficiency and reliability.

Frequently Asked Questions (FAQs)

How can I control the speed of a single-phase motor?

The velocity control of a one-phase engine can be achieved in several ways, as mentioned, including the use of variable-frequency drives (VFDs) and phase-control techniques. VFDs are particularly powerful because they can adjust the frequency of the power supplied to the motor, enabling highly accurate speed regulation. If not, the phase control methods can still be used to account for variations in the motor voltage applied phase angle. For additional benefits, one can opt for the permanent split capacitor (PSC) configuration. Given the many advantages of each method, the preferred method is to be determined by the specific application requirements.

What are the methods of speed control for induction motors?

For induction motors, speed is mainly controlled by adjusting voltage, frequency, and rotor resistance. While rotor resistance control is more commonly used in DC motors, it can also be applied in some induction motor configurations. Voltage control, on the other hand, alters the voltage delivered to the motor, and the frequency control performed by VFDs enables variable motor speed. Knowing the three speed-control methods facilitates choosing the best one for variable-speed operation, especially in industry.

Can a variable frequency drive (VFD) be used with a single-phase induction motor?

Yes, it is possible to connect a variable-frequency drive (VFD) to a single-phase induction motor, although VFDs are more commonly used with three-phase motors. If the VFD is to be used with single-phase motors, it is essential to select a VFD designed for single-phase input to avoid compatibility issues. The VFD’s user will be able to feed the motor with a power supply that offers various frequencies, then control the motor’s speed with great precision. This is a significant advantage for regulating motor speed in applications such as pumps and fans, where speed control is crucial. But users also have to ensure that the VFD matches the motor’s specific voltage and current rating inputs.

What is the difference between single-phase and three-phase induction motors?

The most significant contrast between a single-phase and a three-phase induction motor lies in how they are powered and in their performance characteristics. Single-phase motors rely on a single-phase power source, thus they can be used only in light industrial and residential applications. On the other hand, three-phase motors are powered by a three-phase power source, which gives them more power and torque for heavier loads, thereby making them more efficient. Furthermore, three-phase motors with better speed regulation are standard and are easier to control through VFDs. It is crucial to understand these differences when you are in a position to choose a motor type solely based on the requirement.