Modern aviation is dependent on very thought-out power supply systems to carry out crucial tasks on the ground and in the air. Static frequency converters (SFCs), among others, are the systems that are crucial in the provision of reliable, efficient, and precisely controlled electrical power. This paper dissects SFC technology in terms of the way it functions, the areas where it is used, and its advantages in aircraft power systems. By going through the text, the reader will learn how the converters make it easy for power to be managed, make the use of energy efficient because they work to make aviation infrastructure run in harmony. Whether you are an aviation worker, an engineer, or just a person who is passionate about these topics, this guideline will explain the unique role and industry-wide impact of static frequency converters.

Understanding Static Frequency Converters

Static Frequency Converters (SFCs) are equipment specifically manufactured to provide the power conversion between various frequency standards, which is usually from the 50Hz or 60Hz standard frequency of the mains to the 400Hz frequency needed in aviation and some other applications. This conversion provides a bridge between the earth-supplied power and the high-frequency power used by the airplanes of today. They are the machines that people rely on for providing power to camps at the time of no power supply. They can also be used as protection devices for a power generator, so they have been installed near the power generator, or else, they are installed not so far away.

What is a Static Frequency Converter?

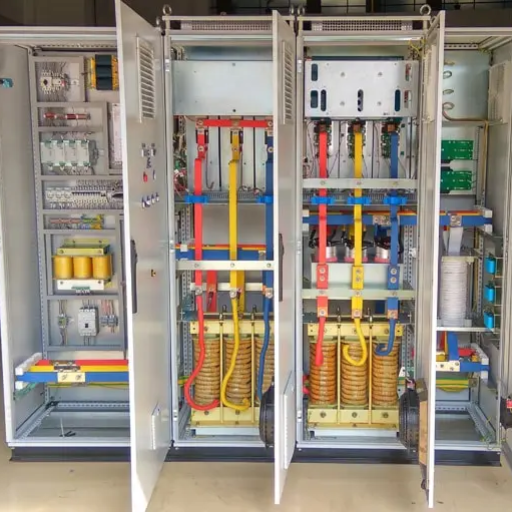

A Static Frequency Converter (SFC) is a sophisticated electrical machine used in power conversion from one frequency to another without the use of mechanical components. Power electronic devices mostly semiconductor like insulated-gate bipolar transistors (IGBTs) are used to perform the necessary conversions, making the process efficient and very accurate. Normally, these systems find their way in the areas where the frequency of the local power supply must be tweaked to match the requirements of certain equipment or systems. The revolution of SFCs has been observed in the aviation, naval, manufacturing, and energy sectors where automatic machinery and apparatus running at non-standard frequencies can be easily interlaced to remove the frequency interruption.

The SFC operates by converting incoming AC power into DC first through a rectifier stage. The DC power is then processed and converted back into AC with the desired frequency through an inverter stage. This approach provides an opportunity for high-precision frequency control with energy efficiency at its best. Current SFCs are capable of tolerating varying loads, they can be easily adjusted to changing power needs, and they are supposed to be fitted with the most sophisticated monitoring and diagnostic capabilities which are believed to be enough to ensure their reliability and long life. Their tough and small form factor, together with the low need for maintenance, makes them a very important part in cases where there needs consistent and reliable power supply at non-standard frequencies.

How Static Frequency Converters Work

Static Frequency Converters (SFCs) is a system which changes its input frequency into another output frequency through the use of power electronic circuits and control systems. The function starts when an alternating current (AC) is converted to Direct Current (DC) by a rectifier circuit; this DC voltage is then transformed into an AC current of the necessary frequency and at the voltage level needed by an inverter. For the inverter stage, modern pulse-width modulation (PWM) techniques are the common elements that guarantee the exact and smooth production of the waveform, thus lessening the harmonic distortion.

Modern SFCs just use updated semiconductor components like the insulated-gate bipolar transistor (IGBT) that also contribute to their cost-effectiveness and dependability. Using these components and the integrated control systems that also keep a close watch on parameters like voltage, frequency, and load conditions, gives the system the capability to immediately adjust for the needed stability and be able to perform according to the application needs. It is also good to note that protection features like overvoltage, overcurrent, and thermal safeties are included in the system to add up to its safety and long life operation.

The above-mentioned systems come with a wide range of applications, ranging from aerospace and defense, industrial manufacturing, and renewable energy systems, where frequency conversion that is both precise and stable is very important for the equipment to be able to work smoothly under the specified power conditions.

Key Differences between Static and Rotary Frequency Converters

| Feature | Static Frequency Converter | Rotary Frequency Converter |

|---|---|---|

| Operating Principle | Uses solid-state electronics | Combines motor and generator systems |

| Efficiency | High efficiency, minimal energy loss | Lower efficiency due to mechanical components |

| Maintenance Requirements | Minimal, no moving parts | Regular, moving parts require servicing |

| Noise Levels | Silent operation | Noisy due to mechanical movement |

| Size and Weight | Compact and lightweight | Larger and heavier |

| Startup Time | Quick, nearly instant | Slower, involves mechanical start-up |

| Durability | Highly durable, fewer wear-prone parts | Susceptible to wear from mechanical components |

| Cost | Typically lower cost | Higher cost due to mechanical complexity |

| Output Stability | Very stable output voltage and frequency | Slight variations due to mechanical factors |

| Applications | Ideal for sensitive and precision equipment | Suited for high-power industrial applications |

| Scalability | Easy to scale up | Less scalable, design limitations exist |

| Environmental Factors | Less affected by surroundings | Performance influenced by vibration and temperature |

Industrial Applications of Static Frequency Converters

Aerospace and Defense

At airports, aircraft ground support equipment keeps the airplanes fully operational, and avionics systems must be tested continuously at a steady frequency.

Manufacturing

CNC machines and robots using high precision also need to have frequency control for the best performance across different applications.

Renewable Energy

The incorporation of wind turbines and solar power systems for energy output synchronization with grid requirements and its adaptation.

Marine and Shipping

One of the key factors here is the provision of continuous and stable electricity to ships from a shore-based system.

Testing and Research Laboratories

Providing an intended environment for testing products, where control of the frequency is a must.

Use in Electrical Power Systems

Because of their accuracy, durability, and flexibility, stationary frequency converters (SFCs) have found their way into the electrical power systems and also the renewable power systems of today to the point that they cannot be left out. One of their major advantages is the freedom to connect power grids of different frequencies such as the 50Hz and 60Hz ones, thus enabling the effective exchange of power between regions or countries that have different power standards. In addition, SFCs are necessary for renewable energy systems owing to their ability to manage variable outputs from wind or solar sources and turn them into stable and grid-compliant power.

Static frequency converters are very common converters in industry, where they are synchronized with the mains or the grid to optimize the operation of equipment affected by frequency variations, such as motors and compressors. By having industrial plants that include such converters into their structure, overall energy waste and thus operating cost can be limited as well as the service life of essential machinery can be prolonged. Moreover, the converter technology has now taken a different direction where its major concern is the design of a more compact and modular product to the market and hence strives to become the best in the world also in the field of energy conversion.

Applications in Aerospace and Defense

Static frequency converters (SFCs) are important in aviation and military because of their accuracy, safety and flexibility requirements. The most popular function of SFCs in aviation is the ground power units (GPUs) for airplanes. These converters provide the necessary 400 Hz power to the airplane systems during maintenance and loading operations, which means pilots no longer need to run the engine and the result is better fuel economy and less harmful emissions.

Moreover, SFC systems are largely employed in defense industries, specifically in the radar, missile navigation, and naval sectors. Their capability of delivering reliable as well as frequency-specific power supplies helps in the precise and efficient operation of sophisticated electronic systems which are indispensable for the success of the mission. The available SFC systems by the time are often equipped with features that enable operations analysis and fault detection in real time, thus adding one more layer of operational stability in harsh or uncertain environmental settings. This leads to an uninterruptible power transfer situation that is a necessity day in and day out in the very high-quality operations of aerospace and defense industry.

Static Frequency Converters in Manufacturing Processes

There is no doubt that static frequency converters are the heart and soul of the contemporary manufacturing industry, regarded as the managers of machinery and hence regulated in the most precise way possible. Among the various possible applications, a very important one is the speed of motor control in industries, which improves the efficiency of the whole process and brings down the mechanical wear together with energy consumption. To mention a converter does another thing, it operates the conveyor belts, robot arms, and high-speed machining tools smoothly by adjusting the supply frequency.

Moreover, static frequency converters upgrade the power (redundancy and quality) for the manufacturing sites that need the electricity to be of the same quality and of high reliability. The better ones may have facilities for the dampening of harmonics and balancing of phases, together with other features that would lead to better energy quality and less of downtowning. What is more, these mechanisms open the possibility for the shift of the manufacturing equipment from one site to another, where different frequencies are used, easing the process and the fines for local regulations on electrical power.

Applications of Static Frequency Converters in Aviation

Static frequency converters are really important when it comes to the field of aviation, as they are the most common source of power to the aircraft during ground operations. They are the ones to attribute the high 400Hz power required by aircraft systems and so kill two birds with one stone – the elimination of onboard auxiliary power units (APUs) or use of engines. This energy saving leads to less pollution and makes possible the eventual eco-friendliness of the sector.

Moreover, static frequency converters ensure cost-effectiveness not only by simple and cheap methods of servicing, but also by speeding pre-flights, as in the case of uninterrupted power supply to the cabins. Moreover, the problem of a turnaround that is too long has been addressed by the use of static frequency converters at airports and by airlines. Besides, their integration with the ground support systems upholds the conformity to the strictest industry standards with regard to power quality and reliability.

Power Systems in Aircraft

Today’s aircraft electrical power systems cannot operate without the use of Static Frequency Converters (SFCs). The reason is that they are the equipment which enables the electrical grid power frequency (usually 50 Hz or 60 Hz) to be raised to the 400 Hz vehicle’s electrical system frequency, and this allows the different systems power sources to be connected in parallel and still maintain compatibility and similar functionality. The new power electronic technology implemented in the SFCs guarantees low harmonic content and stable voltage output, which in turn, are very critical for the avionics and electronic equipment that the aircraft carries.

Moreover, smart fiber converters come with advanced diagnostic and monitoring facilities which allow for monitoring and observation of the operational parameters such as the voltage output, the frequency stability, and the load capacity in real-time. This feature is helpful for predictive maintenance practices and thus helps reduce downtime and improve the reliability of the connected secondary equipment. High energy efficiency and low maintenance requirements when compared to traditional rotary converters put SFCs at the top of the list for airports that are in pursuit of cost reduction and less environmental pollution.

At the same time, the design of new SFCs in different modules also gives them the ability to be expanded and their scalability to be proportionately high in order to deliver the electricity needed by a large group of aircraft. This versatility and the conformance to the newest requirements set by the air industry then lead to the one who achieves the highest cost-effectiveness with the least damage to the environment.

Integration with Ground Power Units

The partnership between Static Frequency Converters (SFCs) with Ground Power Units (GPUs) has brought about a civilizing effect on the way airports supply power to aircraft that are not in motion. The accurate frequency and voltage variations, as delivered by the use of SFCs in combination with GPUs, make the airport infrastructure compatible with different aircraft power demands, which include the 400 Hz essential for modern avionics systems. High-performance SFC-GPU solutions lower the amount of energy lost and they even enhance the effectiveness of the ground operations on the whole.

The very latest overall presents digital monitoring and controlling systems that are a part and parcel of these systems, thus making online diagnostics, predictive maintenance, and switchover between the power sources smooth and painless. These not only abate global ecological footprints, but at the same time, they make the operation very reliable, which is the most important factor when we take into account the extremely intricate nature of the aviation infrastructure that is being dealt with.

Benefits of 400Hz over 60Hz Power Systems

- Reduced Equipment Weight and Size

The 400Hz power systems result in the usage of smaller and much lighter components due to less magnetic material needed in the design of transformers and motors, amongst other devices. For example, a 400-turn core transformer can have a weight of up to 60% lower than a 60Hz one, thus making an aircraft the most beneficial place where weight is a critical issue. - Enhanced Power Density

The 400Hz power systems offer a very high energy output in relation to size, so they are the perfect solution for the applications with limited space and need for the highest efficiency. The versatility of these systems in terms of size and power is of great importance in the aerospace and military industries where area and energy efficiency are the main priorities. - Improved System Efficiency

Higher frequency, power systems usually translate to a range of lesser power loss within certain components for instance, capacitors and inductors, thereby enhancing the entire system’s performance. To illustrate, the investigation demonstrates that systems running at 400Hz can potentially decrease the operation losses in particular setups by 15% in comparison to the 60Hz systems. - Support for High-Performance Electronics

A large number of top-of-the-line gadgets in the aerospace and defense industries are developed with 400Hz power in mind to warrant their peak performance. Such systems are provided with the power that allows for a more seamless working state with much less distortion, thus their capability to be precise in the critical applications. - Compatibility with Aerospace Power Demands

It is necessary to harmonize the requirements of 400Hz power with the high-performance requirements of aerospace and airport ground support equipment. To enhance the performance of multiple aircraft types and ground support equipment, airports have to adopt the same standard. - Lower Magnetic Interference

The 400Hz systems cause less electromagnetic interference when operating at higher frequency compared to the 60Hz systems in some installation configurations. This results in less disruption to the sensitive aircraft navigation and communication systems.

Technical Advantages of SFC in Aviation

- Enhanced Fuel Efficiency

Fuel saving is one of the benefits of using Static Frequency Converters (SFC) in aviation. If the aircraft is plugged into the airport power system for its supply of electrical needs, it becomes superfluous for it to keep its auxiliary power unit (APU) running, which continuously burns jet fuel and emits unwanted gases. - Lower Environmental Impact

The new technology has already proven to be very helpful in reducing the APU’s negative environmental impact by reducing the number of occurrences in which the APU is run. This change not only helps in saving jet fuel but also minimizes the noise caused by commercial planes thus promoting the implementation of the new and very strict environmental regulations for aviation. - Operational Cost Savings

Suppose the APU becomes inefficient and the SFC system takes its place in operations, so fuel cost and avoidable maintenance that arise due to the APU’s frequent use are totally eliminated, and so much money is saved as a result to support the airline’s economically sustainable operations. - Increased System Reliability

The SFC systems provide a state-of-the-art, continuous supply of stable power that ensures the operation of critical aircraft systems is uninterrupted during pre-flight ground activities. Their very accurate performance lowers the possibility of power fluctuations compromising the systems. - Universal Compatibility

The SFC technology is engineered to be super-friendly with several airplane models and it is all because of the standard 400Hz power output. This compatibility makes things easy for airports concerning infrastructure and also for customers in handling the ground operations efficiently.

Solid State Frequency Conversion and Its Benefits

Solid State Frequency Conversion (SFC) is one of the technologies that resulted in the biggest progress concerning efficiency as well as reliability, which actually brought about the necessity of it being a part of some aviation ground power systems. Through the application of highly reliable semiconductor components, SFC systems attain minimal energy loss during the frequency conversion process, and up to 98% of the input power is converted into output power. The compact design and the superiority of the machinery in the latest SFC system lead to a decrease in operating costs, which makes traditional rotary converters incomparable with the premium performance delivery of the SFC systems.

One of the outstanding features of the SFC system lies in the fact that it requires very little maintenance. The conventional systems with their highly dynamic nature leading to wear and tear in the mechanical components have not been completely stopped, but the use of solid-state devices in the place of these elements made it possible for the system to operate longer with lesser downtime. Besides, the technology applied in the SFC is such that it even provides a more accurate control of both voltage and frequency; this way, it guarantees good power quality, which, in turn, saves the avionics systems and the electronic equipment from being easily accessed and hence prone to failure.

SFC systems’ environmental friendly design is one of the most notable benefits. They have a smaller physical footprint and a considerably lower level of noise pollution while working, which makes them in line with the green drive and increasingly stringent laws in all aviation sectors around the world. In addition, the gradual upgrading of the modular SFC components is now the industry norm, allowing power scalability to be easily managed by both small regional and the major international airports with the different power requirements.

Efficiency and Reliability of Static Frequency Converters

SFCs are so appreciated for the best efficiency and operational dependability that they bring to modern power systems. The maximum energy loss that high-performance SFCs may suffer is 5% which amounts to a very small part of the total energy during the process of electrical frequency conversion. As a result, they are used in such sectors as aviation support, high-speed rail systems, and industrial automation where power losses are even marginal and may finally end up as high cost over the years.

At the same time, reliability is very good and is obtained through top quality power electronics and enhanced cooling systems, which aid the running of the unit continuously, even under its peak loads. The best example is the fact that their modular structures come with a fail-safe mode, and the system can be run continuously even in the event of a component failure. In addition, SFCs are able to maintain their high performance under a different power load without any loss and that is why they are essential for the facilities that need exact and stable power outputs.

Impact on Electrical Power Stability

Solid-state frequency converters (SFCs) are essential for the provision of electrical power stability to a higher level through which voltage variations and frequency changes are kept under control. SFCs balance the power outputs with an extraordinary level of precision by means of their sophisticated digital controls; in this way, the power supply to equipment that is sensitive and crucial to the mission is always available and consistent. As an instance, industries like semiconductor manufacturing and medical imaging, where the equipment is high-performance and thus requires a reliable power supply with minimal harmonic distortion and within very stringent tolerances, would benefit a lot from SFCs.

One of the most important aspects of the changes that supergrid or superflexible cables can make is their ability to respond dynamically to load changes by changing the output parameters almost instantaneously. They are very quick in this respect. Systems will not be disturbed or damaged by transient overloads, which occur frequently in traditional power systems. Additionally, it has been proven by actual measurements that SFCs significantly improve the overall system reliability by their merits like less frequent supply interruptions and longer life of the connected infrastructures. These improvements have created new reliability paradigms in all manners of sectors.

Economic Impact of SFC in Aviation

The use of static frequency converters (SFC) in the field of aviation has become the main reason for the reduction in the cost of operations and an increase in efficiency. The use of SFCs enables aircraft to get power from the ground-based systems directly, thus no need to use auxiliary power units (APUs) that are very fuel-intensive during the time of ground operations. This shift does not only cut the need for fuel but also brings about a reduction in the service life of APUs in terms of maintenance and thus, reduces the costs.

In addition to this, SFCs’ increase in energy efficiency also results in airports having to pay less for energy, making such power now the best bet for a financially sustainable solution. The reduced environmental externalities and the increased infrastructure reliability over time plus the corresponding lower repair and replacement costs all go to the economy and the commercial sustainability of SFCs in the aviation industry is further strengthened by all these factors.

Cost Savings from Efficient Power Conversion

If you have Efficient power conversion technologies at your place, then it is sure that you will be able to save a lot. This technology will really make things come true for you by optimizing the usage of the energy and waste reduction. The latest advances in the Solid Oxide Fuel Cells (SOFCs) can give you a light of your electricity problem as they can use it with an efficiency rate of more than 60%, which is way more than the regular power systems. The electricity plus heat from the waste heat recovery can lead you up to an 85% efficiency, with the benefits of both the electricity generated and the thermal energy utilization.

In the case of fuel consumption, these technologies work in such a manner that a very high amount of fuel is saved, thus, the operators can save money on the cost of operation. Furthermore, the earlier admitted discrepancy within the fossil fuels is being crossed over, which in turn will lead to less risk as the fluctuations in the fuel market are minimized. More and more industries are contemplating and adopting the use of these technologies in light of the immediate as well as the long-term economic benefits such as cost-savings, financial predictability, and resilience.

Long-Term Investment in Static Frequency Converters

SFCs (Static Frequency Converters) are quite a significant electromechanical investment for industries desiring strict power control. The technologies are such that they allow perfect energy utilization by allowing the shift of electrical frequencies to the needed operations, thus curbing any energy waste and at the same time making it easy to bring them into different kinds of infrastructure. The trend heading towards the use of SFCs is in alignment with superior power-saving technologies advancing and at the same time showing an increase in the converter industry worldwide.

Market data highlights that sectors like aviation, marine, manufacturing, and renewable energy are embracing SFC technology very strongly primarily because of its reliability and cost-effectiveness. To illustrate, using improved voltage and frequency control, SFCs upgrade equipment performance as well as they increase machine life, leading to less maintenance costs. This convergence of energy efficiency and longevity makes static frequency converters a very important part of the assets of those companies that are going to cut their operational costs and be more environmentally friendly at the same time.

In addition, the constant improvements in power electronics and the worldwide drive for sustainability have made the use of SFCs for the sake of energy saving unquestionably necessary. Due to this development, governments and companies have been pushing the adoption of such technology and the reports revealed a huge increase in the number of new installations, especially in the areas going through a fast-pace industrialization and infrastructure development. By the acquisition of static frequency converters, the firms are not only investing, but also future-proofing their operations to be at par with the energy demands of the future.

Comparative Analysis with Traditional Power Systems

| Feature | Static Frequency Converters | Traditional Power Systems |

|---|---|---|

| Energy Efficiency | High due to optimized power management | Moderate with notable energy loss |

| Installation Flexibility | Compact and adaptable setups | Requires significant space and design |

| Performance in Load Variability | Stable across fluctuating loads | Performance may decline under variability |

| Maintenance Requirements | Low; fewer mechanical components involved | Higher due to complex mechanical systems |

| Response Time to Changes | Fast response to dynamic conditions | Slower response due to limitations |

| Environmental Impact | Minimal; supports renewable integrations | Higher with greater resource consumption |

| Initial Cost | Higher due to advanced technology | Lower; simpler components used |

| Scalability for Upgrades | Easily scalable to evolving needs | Limited scalability potential |

| Operational Lifespan | Extended due to advanced technology | Moderate; wear limits longevity |

| Suitability for Emerging Grids | Highly compatible | Limited compatibility with modern grids |

Reference Sources

- Static Frequency Converter for Large Pumped Storage Units

Read more here - A Review and Comparison of Transformer and Static Frequency Converters

Read more here

Frequently Asked Questions (FAQs)

What is frequency, and why does it matter for SFC applications?

Frequency can be better understood as the number of alternations an electric power makes in a second; the unit of measurement for this is commonly referred to as hertz. Frequency plays a vital role in determining motor speed and timing in different situations. Thus, in the constant frequency converter case, the equipment can be running on different grids if the frequency is controlled to run at 50Hz or 60Hz, nevertheless. The converter which does this can be utilized to feed the required power for ground support of aircraft and other emergency services, by selectively picking the loads, they can be in 60hz power or special 400Hz loads.

How does an SFC operate in electrical power systems?

A solid state frequency synthesizer is a device that generates an AC signal at a certain frequency by first converting the incoming AC to DC and then using power electronics to make the conversion without the need for rotating machinery. This method of conversion offers a lot of advantages over the rotary frequency converter-based methods such as fast response, small physical size, and high efficiency. One of the main applications of the solid-state frequency converter is as an alternative source of 400Hz power for aircraft while also converting supplies at a rate of 60Hz to equipment rated at 50Hz and vice versa.

What is frequency conversion, and how is it applied to 400Hz systems?

Frequency conversion is the transformation of electrical energy from one frequency to another. This can be seen in the case of electric power conversion from 50Hz or 60Hz to the 400Hz that is used mostly in the aeronautical and aerospace industries. In addition, the conversion process carried out by static frequency converters results in a stable 400Hz output that does not require any motor-generators at all, also making it possible for there to be such mobile and fixed ground power units that can supply aircrafts with ground power effectively. All characteristics of the electrical power, including quality and stability demanded by the avionics, are paramount for the converters, the latter also having to deal with 60 Hz power sources or the earth grid previously supplied by hydro.

What benefits do solid-state frequency converters bring to modern power systems?

Solid-state frequency converters, using semiconductor devices, are able to offer a wide range of benefits including small size, power saving, and a very low demand for maintenance. For these reasons, they are widely used in both the industrial and aviation fields as static frequency converters which are ideal for. They are also the ones that facilitate most aircraft’s ground power needs in international airports by means of this high frequency; however, they are facing with the challenge of meeting the 400Hz requirements, which are expensive and in some cases not available. On the other hand, they can easily connect and work with 60 Hz and 50 Hz respectively. In addition, they are able to serve the environmental issues by being connected to a hydro system as well.