Solid-state frequency converters form a potent tool whose principal role is in present-day electrical and industrial applications. By changing one type of electrical frequency to another with utmost efficiency, power systems can be adjusted for specific operational needs. Seamlessly, frequency converters make sure that imported equipment will work or that a critical power supply can remain stable for some sensitive process industries. This article examines how solid-state frequency converters are used in many areas and how they improve performance, energy efficiency, and operational reliability. Whether you’re an engineer designing something in manufacturing or aviation, you’ll learn how these devices could solve power system problems much differently.

Introduction to Frequency Conversion

Frequency conversion is done to make it compatible with different equipment or system requirements. Usually, this can be achieved by frequency converters, which change the power frequency, so that the power source and the equipment working at a different Hertz level can coexist. The conversion of frequency promotes energy efficiency, reduces wear and tear of equipment, and improves the system’s reliability by allowing smooth operation with different electrical standards. Applications of frequency conversion can be seen in aviation, manufacturing, renewable energy, and the like, where proper adjustments may be required in power.

Key Features and Applications of Frequency Converters

Frequency converters are highly versatile devices designed for changing electrical power frequency, thus having various industrial and commercial applications. These devices become invaluable when different power standards are used, say, a 50 Hz power supply may need conversion to 60 Hz and vice versa. They can also be used to speed up the best control and minimize energy consumption. A recent frequency conversion method may enhance motor efficiency by regulating speed and torque as per load, thereby reducing energy consumption up to 30%.

Because of the digital control integration, frequency converters assure precise operation and system monitoring. Some of them have even been equipped with modern IoT features for remote observation and predictive maintenance. According to industry research, demand for frequency converters will reach a significant level of growth, with the market estimated to hit a USD 30 billion mark by 2030 due to an increasing adoption of energy-efficient technologies.

Common Types of Frequency Converters

- Rotary Frequency Converters

These converters vary the power frequency using mechanical methods, such as motor-generator sets. They are heavy, custom-built, and reliable, well-suited to heavy-duty applications, such as ground power for aviation.

- Static Frequency Converters

These converters use solid-state electronics to provide a more compact and efficient alternative to rotary systems. They also lend themselves to applications that require the fastest responses and minimum maintenance, such as renewable energy systems or automation processes.

- Variable Frequency Drives

A frequency converter is a device used to control motor speed. VFDs are considered energy-efficient and are extensively employed in industrial and commercial HVAC.

The effective use of frequency converters translates into savings in operational costs, equipment life extension, and better environmental performance, thus stressing their importance in modern infrastructure.

Types of Frequency Converters

|

Type |

Key Points |

Parameters |

|---|---|---|

|

Voltage Source Inverter |

Uses capacitors for energy storage |

AC voltage, harmonic components |

|

Current Source Inverter |

Uses reactors for energy storage |

DC resistance, four-quadrant operation |

|

V/f Control |

Maintains voltage proportional to frequency |

Voltage, frequency ratio |

|

Vector Control |

Precise motor speed and torque control |

Magnetic flux, rotor current |

|

Direct Torque Control |

High dynamic performance |

Torque, speed response |

|

AC-AC Converter |

Direct AC to AC conversion |

Efficiency, no DC link |

|

AC-DC-AC Converter |

AC to DC to AC conversion |

Adjustable frequency, voltage |

|

Single-Phase Inverter |

For a single-phase power supply |

Voltage: 230V, low power applications |

|

Three-Phase Inverter |

For a three-phase power supply |

Voltage: 400V, high power applications |

|

Scalar Control |

Simple voltage-frequency ratio control |

Voltage, frequency |

|

Matrix Converter |

Direct AC to AC without a DC link |

Compact, efficient |

|

High-Frequency Inverter |

For high-speed motors |

Frequency up to 3kHz |

|

IGBT Inverter |

Uses IGBT for high-power applications |

High voltage, fast switching |

|

MOSFET Inverter |

Uses MOSFET for high-frequency switching |

Low power, high frequency |

Importance of Frequency Conversion in Modern Technology

Variable frequency drive systems are integral in various technological and industrial applications for efficient electrical energy control. Below are the five points that make a compelling case for its importance:

- Efficient Energy Use

Frequency converters provide energy-efficient control, particularly in industries where energy is of premium consideration. Studies reveal that 40% energy conservation is possible by using frequency converters in motor-driven systems such as pumps and compressors.

- Fine Motor Control

A variable frequency drive allows for fine-tuning the speed and torque of the motor to ensure smooth processes. Control needs to be one hundred percent accurate in conveyor systems and robotics.

- Extended Equipment Life

Frequency conversion assists in prolonging the lifespan of equipment by reducing mechanical stresses during start-up and operation. For instance, slow ramp-up of motors reduces the wear and tear involved with abrupt power surges.

- Renewable Energy Integration

Frequency converters allow for integrating renewable energy generation with the grid (wind turbines and solar inverters). Thus, it adapts the fluctuating currents from renewable sources into usable electricity.

- Reduction in Operational Costs

Further cost benefits from industries include reduced energy, operational, and maintenance costs and longer equipment life. For example, efficient production methods directly translate into improved profits.

Scoring on these five points shows that frequency conversion is the foundation of modern technology, sustaining innovation while promoting some conversions to a green path.

How Solid-State Frequency Converters Work

Solid-state frequency converters use sophisticated electronics to convert an input power supply of a given frequency to the required output. With a general description, there are three stages involved in the process:

- Rectification

Converting the input AC into DC using the rectifiers.

- DC Link

The DC is stabilized and filtered to enable smooth operation and reduce noise from electrical sources.

- Inversion

Using the inverter, convert stabilized DC into AC at the required frequency.

Thus, the whole process is streamlined, providing highly precise output control, making these solid-state frequency converters very efficient and reliable for various applications.

Principles of Operation

Solid-state frequency converters translate AC power into a steady and reliable output, utilizing the latest rectification and inversion techniques to make the application energy-efficient across industries.

Comparison with Rotary Frequency Converters

|

Parameter |

Solid-State Frequency Converters |

Rotary Frequency Converters |

|---|---|---|

|

Mechanism |

Uses electronic components, no moving parts |

Uses a motor and a generator |

|

Efficiency |

High, consistent across sizes |

Varies, better with heavy loads |

|

Maintenance |

Minimal, no moving parts |

Regularly, due to moving parts |

|

Noise |

Quiet operation |

Audible noise |

|

Size and Weight |

Compact and lightweight |

Larger and heavier |

|

Durability |

Long lifespan, fewer breakdowns |

Durable but requires maintenance |

|

Cost |

Cost-effective for small applications |

Cost-effective for large applications |

|

Power Capacity |

Ideal for small to medium loads (<5 kVA) |

Ideal for large loads (>10 kVA) |

|

Output Precision |

High precision, stable sine wave |

Handles in-rush currents effectively |

|

Applications |

Aerospace, precision tools, clean power |

Heavy machinery, industrial equipment |

Key Components of Solid-State Converters

First of all, we realize the components of a system that need to work in harmony to produce correct and efficient power conversion:

- Rectifier

The rectifier converts AC into DC power. This component usually uses diode—or thyristor-based circuits for efficient conversion. Modern rectifiers use techniques like active rectification to keep harmonic distortion low and produce good power quality.

- DC Link (Intermediate Circuit)

The link between the rectification and inversion processes is an energy storage and smoothing stage. Separation helps stabilize power delivery towards the downstream; the DC link maintains the voltage steady on the DC side. Usually, this circuit incorporates capacitors and/or inductors, which act to filter out fluctuations and ensure normal working conditions.

- Inverter

The inverter converts the smoothed DC power to AC power of the required frequency and voltage. This apparatus uses advanced semiconductors such as IGBTs or MOSFETs to control the output parameters with extreme precision, achieving energy conversion with very high efficiency.

- Control System

A sophisticated control system will govern the operation of the converter. The modern control system uses a microprocessor or DSP technology to control the switching sequences to derive maximum conversion efficiency and safeguard against fault conditions. Being software-controlled, the system can be tailored specifically for a given industrial application.

- Cooling System:

Heat management remains crucial due to solid-state converters’ exceptional efficiencies and high power densities. The cooling system dissipates all the unwanted heat into the atmosphere, either air-cooled or liquid-cooled.

Data Overview:

- Efficiency: The energy conservation in solid-state converters thus pertains to a selection sale; it renders efficiency above 95%, a better candidate than conventional rotary converters.

- Harmonics Reduction: Improved rectifiers can reduce the THD to below 5%, which is hazardous for sensitive industrial applications.

- Switching Frequencies: The switching frequency of modern IGBT inverters is between 20 kHz and 50 kHz, ensuring smooth and accurate operation.

- Applications: The solid-state frequency converter is widely employed in the aerospace, marine, and manufacturing fields because of its compactness, reliability, and almost maintenance-free mode of operation.

The components and latest technologies discussed make solid-state frequency converters an excellent tool in any industry requiring the best power conversion and corresponding energy efficiency.

Advantages of Solid-State Frequency Converters

|

Key Point |

Advantage |

|---|---|

|

No Moving Parts |

Higher reliability, fewer breakdowns |

|

Low Maintenance |

Minimal servicing required |

|

Compact Design |

Smaller and lighter than rotary converters |

|

Quiet Operation |

Produces little to no noise |

|

High Efficiency |

Consistent efficiency across all sizes |

|

Precise Output |

Stable voltage and frequency control |

|

Energy Saving |

Reduces energy consumption significantly |

|

Remote Monitoring |

Allows for easy remote management |

|

Quick Start |

Always on, no delays in operation |

|

Customizable Features |

Easily tailored for specific applications |

Efficiency and Performance Benefits

- High energy efficiency: Solid-state frequency converters can achieve up to 95% energy efficiency, thus significantly reducing power losses and eventually lowering operating costs.

- Improved voltage regulation: These converters provide accurate and stable voltage regulation, which ensures consistent performance for sensitive equipment and reduces the damage caused by voltage.

- Reduction in harmonic distortion: Designs are modern enough to reduce harmonic distortion, resulting in a cleaner power output, which is beneficial for the operation of high-end machines.

- Compact Size and Less Weight: Because of their small size and lightweight, solid-state frequency converters are easy to install and thus suitable for applications where space and weight capacity are at a premium.

- Longer Equipment Life Cycle: Delivering stable and reliable power helps reduce mechanical stress on connected equipment while prolonging its operational life.

Durability and Maintenance Considerations

Robust construction coupled with highly dependable behavior allows these solid-state frequency converters to be used in heavy industrial applications. One of the primary reasons for their longevity is the absence of moving parts; hence, unlike a rotary converter, they do not undergo wear and tear. Recent studies suggest that, dependent upon the frequency of use and environmental conditions, a well-maintained solid-state frequency converter has a useful life well over 20 years.

In terms of maintenance, said converters demand only simple procedures. Regularly inspecting for irregular temperatures or overheating in the devices, cleaning for proper ventilation, and checking on all electrical connections would ensure that the device continues working at its prime and prevents situations that could cause it to fail. Data indicate a potential 30% reduction in downtime should these maintenance strategies be applied.

One crucial factor to consider in the design of solid-state converters is the choice of materials. Many contemporary models are fitted inside a sturdy casing to shield them from dust, moisture, and other aggressive environmental elements. This robustness is further accentuated by the sound thermal management system, which facilitates heat dissipation from critical parts of the frequency converter to protect its internal components.

The other feature is the integration of diagnostic and monitoring tools, including remote condition monitoring systems, which provide real-time performance status data. This information then serves as a basis for undergoing predictive maintenance, thereby avoiding unexpected failures. Industry experts claim that embracing predictive maintenance technologies reduces repair costs by 20-25%.

Thus, these robustly constructed, low-maintenance, and intelligent diagnostic systems hold solid-state frequency converters as a long-term, dependable, and efficient solution to powering equally critical applications while maintaining lifecycle costs at the lowest possible tally.

Cost-Effectiveness Over Time

A solid-state frequency converter can significantly reduce operating expenses and lifecycle costs via predictive maintenance technology and diagnostic systems, so it is considered cost-effective.

Industries Utilizing Solid-State Frequency Converters

|

Industry |

Key Applications |

|---|---|

|

Aerospace |

Aircraft power systems, 400 Hz conversion |

|

Military |

Radar systems, naval ship power |

|

Pharmaceutical |

Precision tools, clean power supply |

|

Scientific Research |

Laboratory equipment, stable frequencies |

|

Manufacturing |

CNC machines, conveyor belt control |

|

Healthcare |

Hospital equipment, reliable power |

|

Universities |

Research facilities, testing equipment |

|

Marine |

Shore power for ships |

|

Energy |

Renewable energy systems |

|

Transportation |

Electric vehicle charging stations |

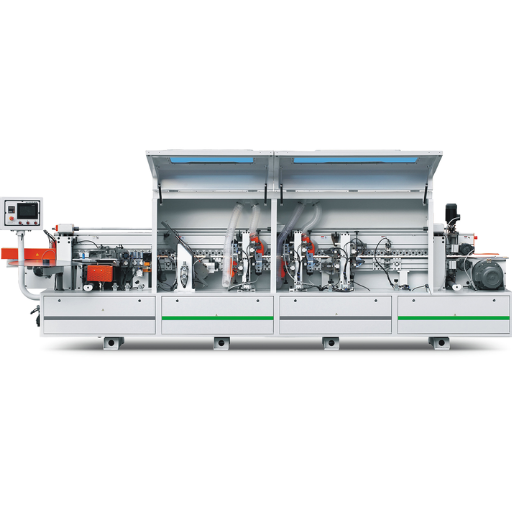

Manufacturing Applications

Solid-state frequency converters are of great importance in modern manufacturing, providing the utmost precision in controlling machinery and equipment. They efficiently convert frequencies to resolve issues between the power supply and industrial devices when equipment works on several standards across countries. For example, with such converters operating, equipment of a 50 Hz standard in one place can easily be provided with a 60 Hz power supply in another place, and vice versa, promoting the idea of global standardization of equipment.

With the surge in demand for optimized production processes and energy-efficient products, industries have observed approximately a 15% growth in the manufacturing-based employment of these converters in the last five years. Applications that employ frequency converters include CNC machining, robotics, and high-speed assembly, where precision in timing and consistency are critical. Such implementation reduces downtime by 20% due to its reliability and compatibility with predictive maintenance programs.

More so, early adoption by the automotive and electronics sectors exploited the efficiencies bestowed by these converters to improve productivity and reduce energy costs. It is expected that the global manufacturing of solid-state frequency converters will cross the $2.5 billion mark by the year 2030, further testifying to their indispensable role in industrial operations.

Renewable Energy Sector

In the variance of renewable energy, these converters are instrumental in integrating particular renewable energy sources into the power grid. The variable generation style of renewable energy requires stringent frequency regulation and voltage stability control. The following are five points illustrating the solid-state frequency-converter-based contributions in this sector:

- Wind Power Integration

A converter settles the difference in output frequencies from wind turbines to ensure a steady power supply to the grid and improve the safe and efficient use of wind power.

- Solar Power Systems

A converter synchronizes the solar PV system output with the grid frequency to ensure maximum power transmission and reduce distribution network losses.

- Energy Storage

This converter coordinates the charging and discharging of battery energy-storage systems by monitoring power flow and frequency, thus underpinning the overall reliability of renewable energy systems.

- Hybrid Energy Systems

These converters act as major enablers for the inculcation of hybrid systems, which combine several renewable sources, such as solar and wind, to maximize energy output and grid stability.

- Grid Stability

Through frequency regulation enhancement, converters can help mitigate grid disturbances and make the power system more resilient when renewable energy inputs become unstable.

In renewable energy applications, upward adoption trends for these converters have been witnessed, and market reports foresee this industry growing at a CAGR of almost 6.5% by 2030, as the demand for sustainable and efficient energy solutions increases.

Transportation and Automotive Use Cases

Converters have been essential in developing electric vehicles and hybrid technologies across the transportation and automotive industries. Given their role in managing energy flow among the battery, motor, and auxiliary systems in an electric vehicle, power electronic converters like DC-DC and inverter systems help achieve high efficiency and low energy losses, along with being lightweight and compact, thus making the electric vehicle practical and attractive to the customer.

Recent data points to a growing number of people adopting electric vehicles worldwide. The International Energy Agency (IEA) acknowledged in a major 2023 report that global sales crossed the 10 million mark in 2022, thus translating to a 55% hike in sales against 2021. This explosive growth is behind upgrading converters to convert a greater range and faster charging.

Furthermore, enormous progress in wide-bandgap semiconductor technology, such as SiC and GaN components, has given a fresh impetus to power conversion in contemporary EV layouts. These materials offer higher efficiency and power density, thus assisting automotive manufacturers in fulfilling higher energy-efficiency targets. For example, SiC-based converters currently find widespread approval in high-voltage EV powertrains to curtail conversion losses significantly during operation.

On the other hand, the converter market for the transportation sector is predicted to grow at a healthy pace and is projected by analysts to register approximately an 8% compound annual growth rate (CAGR) from 2023 to 2030. The upward movement is attributed to growing government incentives for EV adoption and consumer demand for sustainable transportation. This shows the increasing importance of converters in reshaping automotive technology and fulfilling the global electrification agenda.

Future Trends in Solid-State Frequency Conversion

| Trend | Key Points |

|---|---|

|

Integration with IoT |

Enables remote monitoring and control |

|

AI-Driven Optimization |

Enhances efficiency and predictive control |

|

Compact Designs |

Smaller, lighter, and more efficient units |

|

Wide-Bandgap Semiconductors |

Improves performance and reduces losses |

|

Smart Grid Compatibility |

Supports renewable energy and microgrids |

|

Energy Efficiency Focus |

Aligns with global sustainability goals |

|

Advanced Cooling Systems |

Manages heat in high-power applications |

|

Bidirectional Power Flow |

Enables vehicle-to-grid and energy storage |

|

Cost Reduction Efforts |

Focus on affordability for wider adoption |

|

Enhanced Power Quality |

Reduces harmonic distortion and surges |

Advancements in Technology

From the beginning of the twentieth century to today, many advances have been made in semiconductor devices and their basic applications, including frequency conversion. This phase of conversion was traditionally done using electrons and sound waves. Modern science is pushing hard to develop smaller, compact, easy-to-work, high-power-density converters. Much research is being done on materials with wider band gaps, such as silicon carbide (SiC) and gallium nitride (GaN). By looking in such directions, performance could be improved with less loss at higher temperatures and voltages, broadening the range of applications.

Potential New Applications

With the advancements in power electronics and WBG materials such as SiC and GaN, many new applications are being developed across industries.

- Electric Vehicles (EVs): Power converters are instrumental in the rapid upsurge of the electric vehicle market. Latest data suggest that the global electric vehicle market size is projected to reach $823.75 billion by 2030, at a CAGR of 18.2% from 2021 to 2030. Hence, SiC- and GaN-based converters permit rapid charging alongside the aforesaid advantages of efficiency and lesser power losses to aid the EVs in their performance and extend the distance.

- Renewable Energy Integration: With the continued transition to renewable energy sources such as solar and wind, the momentum remains high to develop inverters and converters with the best possible efficiency. WBG materials thus allow for higher energy conversion towards grid integration, specifically regarding solar inverters. Reports show that the global solar inverter market is expected to top $18 billion by 2028, further accentuating immense development opportunities.

- Aerospace and Defense: These two industries benefit from compact, lightweight, and efficient power systems made possible by wide-bandgap materials. Currently, the aircraft power systems and SiC-based converters are facilitating greater fuel efficiency and lower emissions than existed before in electric and hybrid airplanes.

- Data Centers: Data centers that dissipate a ton of energy consume nearly 1% of electricity across the globe. The SiC and GaN power electronics’ voltage regulation and power delivery applications continuously reduce energy losses, making it better for a sustainable IT infrastructure. Research suggests a 5-10% in top potential in the energy efficiency due to a switch to these advanced materials.

- High-Frequency Applications: Advances in GaN technology heighten the effectiveness of high-frequency power conversion. This is important for emerging technologies such as 5G infrastructure, which demand designs with low power loss and compactness.

The interaction of these technologies creates a significant paradigm shift in industries operating from transport to energy management and telecommunications. Further investments in developing wide-bandgap semiconductors will undoubtedly increase the scope for additional applications, thus presenting enormous opportunities for newer possibilities and markets.

Challenges and Solutions in the Industry

The proliferation and adoption of wide-bandgap semiconductors encounter some impediments. Below is an elaborate description of the five main challenges considered paramount and their respective potential solutions:

- High-Cost Materials

- Challenge: Materials used in wide-bandgap technology, meaning silicon carbide (SiC) or gallium nitride (GaN), tend to be very expensive compared to standard silicon. This abnormal upfront expense often deters widespread adoption.

- Solution: Large-scale production capacity with improved techniques for material synthesis should push prices down. Owing to increased market competition alongside progress in manufacturing technology, raw material costs may further drop with time.

- More Complex Manufacturing

- Challenge: The manufacturing processes for wide-bandgap semiconductors are more complex and involve special equipment, with considerable time and resources invested in their manufacturing.

- Solution: Research focused on superior fabrication methods for bulk crystal growth or thinner substrate layers may help simplify the manufacturing process. Industry-wide cooperative approaches to sharing new methods will also ease the concern.

- Thermal Issues

- Challenge: Wide-bandgap semiconductors can operate at elevated temperatures, but devising thermal management systems suitable for compact designs is difficult.

- Solution: The Development of advanced thermal interface materials (TIMs) and heat sinks should dissipate heat effectively. Meanwhile, an engineer can aim to optimize the circuit designs to complement the thermal behaviors of these semiconductors.

- Shortage of Technical Workforce

- Challenge: The industry needs a highly qualified workforce to design, manufacture, and integrate wide-bandgap semiconductors, yet the pool of professionals remains quite limited.

- Solution: Investing in workforce training and partnering with academic institutions to ramp up the talent supply chain are viable options. Governments and private bodies can also provide scholarships or incentives to encourage expertise in this field.

- Compatibility Issues with Current Infrastructure

- Challenge: Wide-bandgap semiconductor devices almost always mandate changes in the existing systems and infrastructure, causing compatibility problems and extra costs to the end user.

- Solution: Developing industry standards and cross-compatible systems can guarantee seamless integration. Testing these standards and providing support with detailed instructions for manufacturers and users will also help solve related problems.

By systematically tackling these challenges, the industry will be able to unlock the potential of wide-bandgap semiconductors, thereby speeding up adoption in diverse sectors.

References

-

Solid-State Transformers for Interfacing Solar Panels to the Power Grid

- This paper discusses the use of high-frequency transformers and power converters in solar panel applications.

- Read the paper here

-

Analysis and Design of High-Frequency Soft-Switching DC-DC Converter for Wireless Power Charging Applications

- This study explores the design and applications of high-frequency DC-DC converters in wireless power charging.

- Access the study here

-

Effect of Solid-State Power-Converter Harmonics on Electric-Power-Supply Systems

- This research examines the impact of solid-state power converters on electric power supply systems, focusing on harmonics and standards.

- View the research here

- Top Static Frequency Converter Suppliers in China

Frequently Asked Questions (FAQ)

What are solid frequency converters?

Solid frequency converters are electronic devices that convert power frequency from one level to another while maintaining the quality of the output signal. They are often utilized in industrial applications to match the frequency of electrical systems, ensuring compatibility with various equipment and machinery.

What are the applications of solid frequency converters?

Solid frequency converters are used in various applications, including renewable energy systems, industrial motor drives, and variable speed drives. They also find applications in telecommunications, aerospace, and marine systems, providing reliable power conversion and frequency control.

How do solid frequency converters work?

Solid frequency converters use power electronics to regulate and convert electrical energy. They typically involve rectification, inversion, and filtering processes to convert AC power from one frequency to another while ensuring efficiency and minimal harmonic distortion.

What are the advantages of using solid frequency converters?

Solid frequency converters offer improved energy efficiency, reduced maintenance costs, and enhanced operational flexibility. They also provide precise control over frequency and voltage, which is essential for sensitive equipment and processes.

In which industries are solid frequency converters commonly used?

Solid frequency converters are commonly used in manufacturing, oil and gas, transportation, and renewable energy industries. Their ability to adjust frequency makes them essential for applications that require synchronization between different electrical systems.

Are solid frequency converters environmentally friendly?

Yes, solid frequency converters can be considered environmentally friendly. They help optimize energy usage and reduce waste. By improving the efficiency of electrical systems, they contribute to lower carbon emissions and support sustainable energy practices.

What are the key features to look for in a solid frequency converter?

When selecting a solid frequency converter, key features include efficiency ratings, power rating, size, input and output voltage compatibility, and control options. Overload capacity and protection against electrical faults are crucial for ensuring reliable operation.

Can solid frequency converters be integrated with renewable energy sources?

Solid frequency converters can be effectively integrated with renewable energy sources such as wind and solar power systems. They facilitate the conversion of variable frequency outputs from these energy sources to stable grid-compatible frequencies, enhancing the overall reliability and efficiency of renewable energy systems.