AC frequency converter is something so necessary for modern electrical and mechanical systems to be able to speed control motors accurately and thereby make energy-wise usage in numerous applications. They have inadvertently transformed the industries supplying power to industrial machines to assisting in the operation of renewable energy systems. But are you aware that not all AC frequency converters are the same? It will be instrumental to know the types of AC frequency converters available with their features and usage areas so as to make an informed decision against particular needs. If you are an engineer, a technician, or you are just curious as to how these work, this guide will enlighten you about the main types of AC frequency converters and their importance in powering the world around us.

What is a Frequency Converter and How Does it Work?

In terms of a frequency converter, the device must change the existing frequency of the power supply. Then a current is first converted into a direct current through a rectifier. The DC is then converted into AC of the material frequency using the inverter. Because of this, the output will be able to suit many equipment with variable frequencies to perform their best. Generally, frequency converters are employed when equipment has been built for a frequency type that is not the one available locally or when weak-speed motors in industries are to be controlled.

Understanding the Frequency Conversion Process

There are two moving parts to drive frequency conversion: First, the AC from the input source is converted into DC through a rectifier. Next, the DC is converted into AC of the needed frequency by using an inverter. This simple process of conversion enables the output frequency to be according to the frequency requirements of the output so that it can function accordingly with precision and efficiency.

How Frequency Converters Affect Voltage and Frequency

Frequency converters are crucial for the regulation of both voltage and frequency, keeping them at the required levels for specific electrical equipment. They regulate frequency and either increase or decrease voltage levels to maintain the stability of operation. Hence, while changing the frequency, the converter also changes the amplitude of the voltage to ensure the performance of machines that require certain electrical specifications.

At present, various operations get optimized with high-tech frequency converters using PWM (pulse width modulation) technology. For example, when the frequency of an AC power source is increased or decreased, the voltage must be proportionately altered; else the motor may get heated up or may not provide satisfactory performance. Industrial applications usually show that most frequency converters have a frequency range from 0 Hz to 400 Hz and voltage linearly adjusted in the same range based on different load conditions.

This represents considerable allowance in improved efficiency with high-performance frequency converters as represented by current industrial reports. For instance, major HVAC systems’ energy consumption was found to be reduced by up to 40% through the installation of variable frequency converters. Besides, stricter voltage and frequency control provided by these converters allows manufacturing plants to reduce wear on motor-driven machinery, thereby extending the average life of equipment by 20%-30%. This makes frequency converters indispensable, not only for ensuring operational accuracy but also in enhancing the energy efficiency and cost effectiveness of all industries.

Common Applications of Frequency Converters

Frequency converters are extensively used in various industries because they adjust motor speeds efficiently according to operational needs. Some examples of their usages are presented below alongside the benefits:

- HVAC Systems

Frequency converters adjust the speeds of pumps and fans to match airflow or fluid requirements under real-time conditions in HVAC systems, thus making the operation energy-efficient. Energy savings are colossal, with studies claiming that energy costs are cut by 50 percent in big installations. With speed maintained almost accurately, the frequency converters thus increase the life of the equipment and reduce maintenance costs.

- Industrial Machinery

Frequency converters are of great advantage in industrial manufacturing plants from production lines to conveyor belts and other heavy machinery. They give accurate speed and torque control to the motors, which enhances both production precision and time for downtime. For plastics and textile manufacture, for example, frequency converters manipulate machine speed for different kinds of materials and for different scales of production to ensure consistency in quality.

- Renewable Energy Systems

Frequency converters play a vital role in renewable energy applications such as wind turbines. They allow efficiently converting the variable speeds of rotor blades into steady grid-compatible electricity, thus bringing stability to wind power output. Modern wind turbine systems equipped with modern frequency converters are capable of energy conversion efficiency of above 90%.

- Marine and Offshore Operations

Some of the industrial applications of frequency converters include propulsion systems, thrusters, and deck machinery of vessels and offshore rigs. In so doing, they increase the reliability of operations and improve fuel efficiency by some 20% in some installations. In addition, the frequency converters smooth the control of shipboard equipment, which is very important under harsh marine conditions.

- Water and Wastewater Treatment

Frequency converters are installed in water distribution and wastewater treatment plants to regulate pump operations. They are adjusting pump speed according to flow demand to minimize energy waste and lower operation costs. It has been reported that using variable speed motor control in these plants can reduce energy consumption by 35%, and this aligns with international efforts toward sustainable water management.

- Mining and Oil & Gas

In mining and oil & gas, the special needs for sustainable, reliable, and robust solutions emerge from harsh operating conditions. Frequency converters improve equipment performance by offering a high degree of control for crushers, hoists, and pumps. They also contribute towards the reduction of greenhouse gas emissions by optimizing energy consumption, a focal point for industries aiming to achieve sustainability goals.

Because of their implementation in these diverse environments, the frequency converters increase operational reliability while increasing energy efficiency and environmental sustainability. Their versatility and relevance to the needs of modern-day industry have made them an integral part of tomorrow’s engineering.

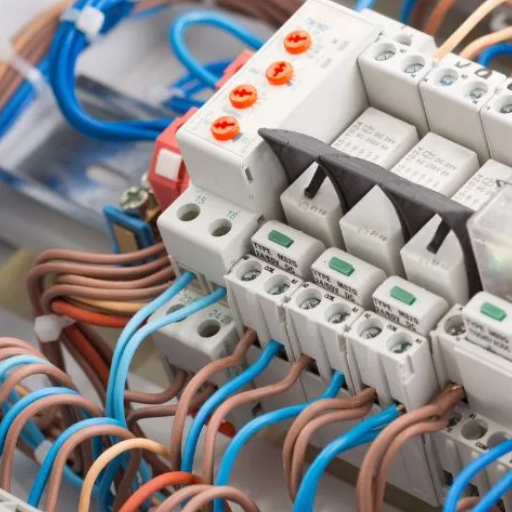

Exploring the Types of Frequency Converters

There are various types of frequency converters, each constructed for a specific purpose.

Static Frequency Converters– Distributed frequency must change by solid-state electronics without any moving parts. Therefore, they should be efficient, compact, and good for precise control.

Rotary Frequency Converter– Works by using the motor-generator arrangement frequency conversion. Such converters are used for high-power applications requiring a robust performance.

Variable Frequency Drives (VFDs)– Such VFDs are designed to provide control on speed for varying frequencies and voltages supplied to the motor. This is common for industrial purposes for conserving energy and controlling the process.

Each has its advantages concerning the application and necessity of operation.

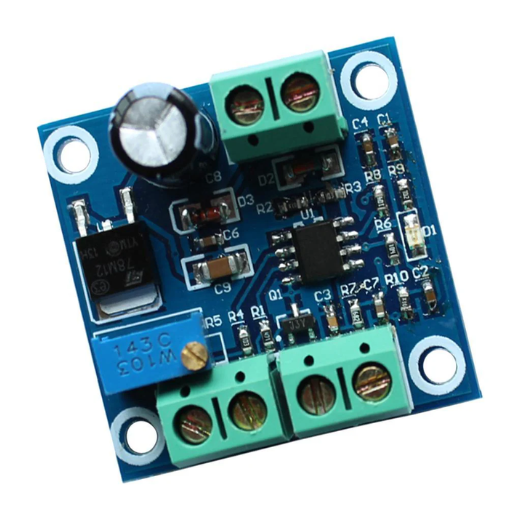

Introduction to AC Inverters

Good inverters convert DC electricity into AC electricity to supply electrical devices and systems. These have applications from solar and wind power systems to industrial motor controls and household appliances.

The modern AC inverter uses technologies to extract maximum energy and ensure a superior conversion. In the renewable sector, the inverter acts in solar power systems to convert DC electricity generated by solar panels into AC electricity for household use or grid distribution. According to some recent studies, state-of-the-art inverters achieve over 98% efficiency so that very little energy is lost in the conversion process.

AC inverters form the core of variable-speed drives used in industries that require precise motor control. These works change the speed of the motors without changing torque, thus saving as much as 50% of energy depending on its application. Moreover, smart inverters with remote monitoring, real-time diagnostics, and grid-supporting capabilities offer a new paradigm in energy management systems.

The AC inverter would be based on the nature of the application such as power range, voltage range, or environmental conditions. With innovation front and energy regulations getting tougher and tougher, AC inverters keep on evolving in terms of uses and sustainability potentials for different applications.

How DC to AC Conversion Works

An inverter takes DC and changes it into AC. It provides a vital link that lets a DC power source like solar panels, batteries, or fuel cells be connected to appliances on an AC supply, or in turn, to the grid.

The DC power enters into the inverter for conversion. The inverter has the high-speed switching properties bestowed by transistors, such as MOSFETs or IGBTs, which turn the DC on and off in an oscillatory manner in a pre-determined frequency and waveform to synthesize the sine waveform of AC electricity. Most grids and appliances use this sine waveform. More sophisticated inverters employ PWM to obtain a smooth and constant AC waveform while maximizing the energy conversion efficiency.

The focus on the new generation has been achieving high inverter conversion efficiency, exceeding 95%, with advances in semiconductor materials and power electronics. Some widely emerging materials in inverter techniques nowadays are silicon carbide (SiC) and gallium nitride (GaN), owing to their superior capability of handling higher voltages and temperatures than silicon with less energy losses.

After the AC signal has been converted, metrics such as Total Harmonic Distortion (THD) will ascertain the quality of the output. Inverter THDs are below 3% for top-of-the-line models, assuring the compatibility of the output AC with delicate electronic equipment. Furthermore, MPPT is being incorporated in many inverter technologies nowadays for optimization beyond solar energy conversion.

Generally, DC to AC conversion is crucial to any modern application or renewable system for sustainable and efficient power delivery.

The Role of Matrix Converters

Power converters that allow for a direct AC-AC conversion without an intermediate DC conversion stage are called matrix converters. This removal of bulky and costly reactive components such as DC-link capacitors yields a compact, lightweight, and efficient system. A matrix converter employs an array of bi-directional switches to modulate input and output voltage waveforms, thereby providing a high degree of flexibility and accuracy in energy management.

One advantage of matrix converters is that they can be run with almost sinusoidal input current and output voltage, with a very low total harmonic distortion (THD) below 5%. Apart from this, they offer bidirectional power flow, which finds application in scenarios where energy might be recuperated or braking may be regenerative, such as in advanced motor drives, transportation, or industrial automation.

Lately, further enhancements in matrix converters demonstrated that they could offer efficiency of up to 97%, thus outperforming conventional converter systems in their optimal operating range. Due to a higher power density, they have candidates for high-power applications with space constraints such as in aviation and shipboard systems. Nevertheless, problems such as convoluted control algorithms and the high costs of semiconductor switches have impeded their acceptance worldwide.

What is profitable right now, however, are semiconductor technologies progressing on continuous fronts and may hold the key to unlocking high-performance, reliable, and cheaper matrix converters, primarily through wide-bandgap semiconductor materials: silicon carbide (SiC) and gallium nitride (GaN). With the unfolding advances in this domain, matrix converters are likely to find critical applications toward efficient and compact power conversion systems across industries.

The Working Principle of Frequency Inverters

The period of frequency inverter operation is from the conversion of a fixed frequency AC supply to a variable frequency output. The whole process combines the following three steps:

Conversion – The AC power coming is converted into DC power through a process called rectification. This step provides a steady DC voltage for the next processing steps.

DC link stabilization – The DC power is smoothed and regulated by capacitors or inductors to provide a consistent output.

Inversion – The stabilized DC power gets converted into AC power of required frequency and voltage using an inverter circuit. Frequency and voltage adjustment allows speed and torque control of the motors attached very precisely.

This allows the frequency inverter to adjust the operation of the motor according to specific installation requirements such as with energy saving and performance enhancement.

How Transistors are Used in Inverters

In the working model of an inverter, transistors perform high-speed electronic switching, thereby controlling the conductance of electrical power. Present-day inverters mostly employ IGBTs or MOSFETs, both boasting efficiency and reliability.

Switching Functionality – The transistors are to switch back and forth rapidly between the conductance and resistance of electrical signals. In this capacity, by following certain on/off sequences, the switching transistors of an inverter create AC signals from DC sources.

High Efficiency – IGBTs are capable of operating at high voltages and currents while dissipating very little power. This makes them suitable for industrial applications such as driving heavy-duty motors and works of renewable energy generation. For example, the IGBT switching frequency spans from 5 to 30 kHz, thus enabling the generation of smooth AC waveforms.

Pulse-Width Modulation (PWM) – Transistors play an important role in all PWM-based inverter techniques. With the accurate switching sequence of transistors, the value of output voltage and frequency is specified, thus ensuring high-performance control for VSDs and solar inverters.

Dissipation of Heat and Reliability – To manage thermal performance during the functioning stage, transistors are sometimes provided with additional evacuating systems apart from heat sinks. Transistor-based systems can operate safely on any load and temperature condition, thus ensuring long life and reliable performance.

The Importance of Sinusoidal Output Voltage

The output voltage is crucial as it must be sinusoidal in the efficient and stable operation of devices and systems. Sinusoidal waves are very similar to the electricity being generated, transmitted, and distributed into nature. It’s all about minimizing losses and raising compatibility with electrical components. Non-sinusoidal waveforms like square and triangle waves have harmonic distortions; hence they pose energy loss, increase heating within components, and interference, or in some cases, equipment malfunctions.

Another important benefit of sinusoidal output voltage is that it reduces Total Harmonic Distortion (THD). In contemporary settings, an inverter used in renewable energy systems or industrial AC drives would be manufactured such that it always produces sinusoidal output signals with a THD level of less than 3%, thereby ensuring the delivery of clean power. Low THD protects sensitive equipment and thereby increases the efficiency of energy use in systems.

The sinusoidal voltages also ensure that the transition across all sorts of loads, be they purely resistive or have inductive and capacitive characters, is smooth. A typical case would be in motor controls, where the sinusoidal waveform ensures that the motors run smoothly with less noise and consume less energy. Also, an evaluation carried out on industrial motors has proven that in respect to energy consumption, using sinusoidal outputs can save 25% compared to non-sinusoidal outputs.

Most power grids of the world are designed for sinusoidal operation; their operation hence lies within set grid standards sticking to these standards ensures device compatibility with the grid and helps avoid penalties for injecting nonsinusoidal currents that could destabilize the network.

The significance of sinusoidal output voltage is, therefore, on the rise with the introduction of renewable energy and sophisticated electronic equipment. Maintaining high-quality sinusoidal signals is very important for the realization of efficient operation, reliability, and long life of modern electrical systems.

How to Choose the Right Type of Frequency Converter for Your Needs

To select the right frequency converter, one must begin with the application requirements for the particular case. Values to consider include the power rating of the motor to be controlled and whether the converter is rated for that power level. Other necessary considerations are the voltage supplied and the type of phase, being single-phase or three-phase, as these must match the system.

Now, another set of crucial criteria comes into the picture. Depending on the operation, there could be a requirement for accurate speed control, energy-saving modes, or torque adjustment. Should the application pose challenges, the converter should incorporate features such as program controls or safety functions that are suitable for the job. And, finally, consider environmental factors; a rugged converter sealed against ingress may be required in hazardous or extreme environments.

Lastly, the company and its products’ reputation must be addressed. It is best to choose a well-known brand since good service has ensured its name, which will prove vital when performance or servicing issues arise. Consider the product’s manual alongside any other reviews you can find before working your way to a conclusion.

Factors to Consider: Output Frequency and Voltage

Understand the relationship between frequency and voltage while choosing a power converter for the right performance of your equipment. The output frequency, usually expressed in Hertz (Hz), should be by the requirements of the device connected to it. For example, the standard frequencies in many parts of the world are 50 Hz and 60 Hz. Any device subjected to frequency other than its designated one either malfunctions or operates inefficiently. Industrial needs usually equip higher or varying frequencies to apply to certain equipment.

Maintaining the same voltage rating at output with the rating of your devices is also very important. An output voltage rating higher than that of your devices may overburden them, whereas an output voltage rating lower than that of your devices may render them inefficient. For example, the voltage ratings in the 110-120 volt range are mostly used in North America, whereas those in 220-240 volt range are used mostly in many European countries. For sensitive electronic devices, the need is of a converter with a closely regulated output voltage so that the device can continue to operate without interruption, and any voltage fluctuation can be avoided that can damage the device.

Nowadays, recent developments in power conversion introduced programmable converters that allow the end user to program both frequency and voltage to suit the application. Some converters include advanced features such as real-time monitoring so users can be alerted should values drift out of tolerable operation ranges. Always make sure you know your equipment’s power requirements and check your compatibility twice before making a purchase; all of this assures the safe use of installation and longevity thereof.

Understanding Fixed Frequency vs. Adjustable Frequency

Fixed frequency systems operate at some fixed or predetermined value of frequency (some standard values such as 50 Hz, or 60 Hz). These systems find applications wherever performance needs are crucially consistent- in Household Cookers, factory settings of HVAC units, and so forth. First, the fixed frequency systems are working under the simplest setup-one either designed to work without any change in frequencies, thereby giving it reliability. Adjusting frequency methods and facilities are somewhat complex and require maintenance. Conversely, a fixed frequency system loses a significant degree of its flexibility when load requirements change, or with adverse energy-efficiency concerns.

Changeable frequency systems allow frequency control from time to time under VFDs or frequency converters, matching the needs of an operation. Things are working from day-to-day precision and firm adaptability ability to control start-stop operation, job variable resistance control, and so increasingly common in manufacturing and renewable energy systems. Some examples of adjustable frequency drives are used in motor applications, which under certain circumstances allow saving of energy from 30% to 50% according to industry data. These systems also reduce mechanical wear and tear, thereby extending equipment life.

Though fixed frequency systems could be sufficient for operations with constant conditions, adjustable frequency systems provide flexibility in cases that include energy optimization and a decrease in operational costs. Ultimately, which type to be chosen depends completely on the application requirements and objectives in question.

Evaluating Reliability and Performance

Several factors account for reliability and performance, such as design, quality of material, and operational standards. Due to durability and effectiveness, modern systems are put into increasingly rigorous testing regimes. For example, some studies stated that higher-performance systems can sustain efficiency levels above 95% under ideal circumstances, thus creating very little loss of energy. Also, based on the higher-grade materials used for manufacture, such as reinforced alloys or composite polymers, components may be far more reliable in truly harsh working conditions.

Planning performance-watching and predictive maintenance are other technologies that contribute to the optimization of performance. Research shows that predictive maintenance can reduce unexpected downtimes by 30 percent while increasing productivity and equipment life. Advanced sensor-equipped systems coupled with IoT integration have the best chances to detect an issue before it becomes one, facilitating timely resolution and minimal operational disruption. These enhancements highlight that the delivery of operational reliability remains at the forefront of achieving any long-term operational success.

Advantages of Using Frequency Inverters in AC Motors

Energy Efficiency: Frequency inverters are used to accurately control the speed of a motor, giving the advantage of saving energy depending on the amount of output needed by the motor for a particular load.

Better Process Control: Speeds can be adjusted for precise process control, thus allowing manufacturing and processing tasks to be more efficient.

Reduced Wear and Tear: Increments in acceleration and deceleration lessen pressure on the mechanical parts of the motor as well as on the connected equipment, with this benefiting an increase in their useful life.

Saving Costs: Less use of energy, minimized costs of repair, and increased life period of equipment all converge to save money in due course.

Versatility: Frequency inverters can be used to tune the motor such that the requirements for several different industrial applications can be met.

Benefits of Energy Efficiency and Cost Savings

Energy conservation and economic savings go hand in hand and together they provide great benefits to the industries and businesses. In recent times, energy studies have revealed that the use of energy efficiency measures such as frequency inverters can reduce the energy consumption of motor-driven systems by around 30-40%. So much efficiency means that operating expenses get slashed whilst carbon emission is curtailed, thus enabling a more sustainable environment.

Concerning energy efficiency, industries are granted further financial incentives by governments and tax credits that foster sustainable energy uses. For example, in 2023, policies of several countries were changed to increase subsidization for green technologies to help businesses acquire their energy-saving tools or practices.

Besides being energy-saving, such technology can also increase the reliability of the entire system. Equipment starts functioning more seamlessly when energy is not wasted. This reduces the costs involved in maintaining such equipment and also curtails its downtime. When combined, this obviously would provide a great ROI; hence energy efficiency is regarded as an important contributor to long-term profitability and sustainability in the current world of industry.

How Frequency Inverters Control Motor Speed

Frequency inverters or VFDs, to be precise, constitute a very important part of the whole mechanical control process, controlling the speed and torque of electric motors for a wide range of applications in commercial and industrial purposes for energy saving and productivity. The driving principle is that the speed of a motor is directly proportional to the frequency of the voltage applied to it, which can be kept constant when the other factors remain unchanged. Applications that see loads varying, including heating, ventilation and air conditioning systems, manufacturing, or pumping stations, would thus derive particular benefit from this type of drive.

Frequency inverters, thus, at the most basic level, convert the frequency of AC power from fixed frequency to DC power using a rectifier or DC section. The DC supply is then processed through an inverter circuit by which the magnitude and frequency of supply voltage are controlled. So, if the speed of the motor needs to be reduced to half, the inverter reduces the frequency being supplied to the motor and thus achieves this speed reduction smoothly and energy-efficiently.

The data lies in the realm of energy-saving potential. Studies showed that the installation of frequency inverters on motors can cut down the rate of energy consumption by 20-50% depending upon the application and load variability. Furthermore, it may increase the lifespan of the motors by minimizing stress on start and stop cycles. It keeps reliability elevated, reduces wear and tear, and consequently lowers maintenance expenses.

Further, frequency inverters have been programmed to allow advanced monitoring and control, including automatic fault detections and integration into smart industrial systems. All these help optimize processes on the back end, thereby further lowering operating costs for the businesses.

Being indispensable components in contemporary automation systems, frequency inverters provide industries with vast potentials in energy efficiency, operational versatility, and sustainability.

The Impact on Torque and Performance

Henceforth, frequency inverters have proven indispensable for the increase of torque and enhanced performance for practically every industrial application. For any given application, desired speed and torque implications are imposed on an electric motor regarding loads acting on it. Torque may generally be kept constant irrespective of varying speeds or can be used in dynamic applications at varying speeds. In other words, this is a useful feature for those applications having a high starting torque requirement or load adaptation requirement, such as conveyors, cranes, and mixers.

They are the modern frequency inverters that, with advanced algorithms and vector control technology, provide superior torque output. In particular, vector control allows the currents of the motor to be controlled very accurately, and hence the torque control is extremely efficient even when there are large variations in motor load. Therefore, benchmarking data from industry sources show that equipment using vector-controlled inverters can attain up to 40% more accurate torque compared to conventional control equipment. Also, performance data suggest that energy savings of 20-50% are attained on average in those systems that have dynamically varying speed requirements.

Frequency inverters also help to reduce voltage fluctuations and hence avoid motor overheating, so that in this way the life of the equipment is prolonged, and downtimes for maintenance repairs are curtailed. The key performance indicators suggest that production lines equipped with frequency inverters are rated as having fewer disturbances and higher levels of reliability, thus providing industries with a cost-efficient and energy-efficient solution to meet their varying operational demands. The interplay among torque, speed, and performance is a very important feature that frequency inverters offer in balancing the industrial process for its smooth and efficient execution.

Reference Sources

-

Design and Construction of an Inverter for University ICT Loads:

- Focuses on the design of high-frequency inverters, a type of AC frequency converter.

- Highlights the use of high-frequency inverter topologies for efficient DC-to-AC conversion.

- Methodology includes the design and construction of an inverter system tailored for ICT loads.

-

- Explores the use of fuzzy logic control in high-frequency switching for DC-to-AC converters and three-phase inverters.

- Discusses synchronization of the output voltage in AC frequency converters for photovoltaic applications.

- Methodology involves the integration of fuzzy logic control with SEPIC DC/DC converters and inverters.

-

Multi-Motor Drives for Crane Application:

- Examines the application of frequency converters in modern crane drives.

- Highlights the replacement of conventional AC drives with frequency converter-supplied squirrel-cage motors for improved efficiency.

- Methodology includes the analysis of multi-motor drive systems and their performance in crane applications.

- Top AC Frequency Converter Suppliers In China

Frequently Asked Questions (FAQs)

Q: What are the different types of AC frequency converters?

A: AC frequency converters are devices that convert one frequency of AC voltage to another. Common types include voltage source inverters, current source inverters, and matrix converters. Each type has unique characteristics suited for specific applications.

Q: How does a voltage source frequency converter work?

A: A voltage source frequency converter uses a DC link to convert AC to DC and then back to AC at a different frequency. This type is equivalent to a voltage source and is widely used in various industrial applications due to its ability to control the speed of AC motors effectively.

Q: What role does the power grid play in frequency converters?

A: The power grid provides the input power for frequency converters. These devices can adjust the output AC to meet the grid frequency requirements, ensuring compatibility and efficiency in power distribution and consumption.

Q: Why is overload protection important in frequency converters?

A: Overload protection is crucial in frequency converters to prevent damage to the device and connected equipment. It ensures that the converter operates within its rated frequency and power limits, safeguarding against excessive current or thermal failure.

Q: How do frequency converters control the speed of a motor?

A: Frequency converters control the speed of a motor by adjusting the frequency and voltage of the AC power supply. This allows for precise speed regulation of AC motors, which is essential for applications requiring variable motor speeds.

Q: What is the significance of reactive power in frequency converters?

A: Reactive power is significant in frequency converters as it affects the power factor and efficiency of the power system. Proper management of reactive power ensures optimal performance and energy efficiency of the converters and connected loads.

Q: Can frequency converters be used for energy storage element applications?

A: Yes, frequency converters can be used in conjunction with energy storage elements to provide a stable power supply and to manage the distribution of power in systems where energy storage is necessary for high performance and reliability.

Q: What are the common applications of AC frequency converters?

A: AC frequency converters are used in a wide range of applications including industrial automation, HVAC systems, renewable energy systems, and transportation. They are essential for applications that require adjustable frequency and voltage control for motors and other electrical equipment.

Q: How do frequency converters contribute to lower operating costs?

A: Frequency converters contribute to lower operating costs by improving energy efficiency and reducing wear and tear on mechanical components. By optimizing power consumption and providing precise speed control, they help in cutting down unnecessary energy expenditure and maintenance costs.

Q: What factors should be considered when choosing a frequency converter?

A: When choosing a frequency converter, factors such as the power source, input power requirements, output AC specifications, speed regulation needs, and compatibility with the power line should be considered. Understanding the types of frequency converters and their applications will help in selecting the appropriate device for specific needs.