Rotary phase converters are game-changing devices that are equipment for use in industrial and commercial applications. Such converters create three-phase power out of single-phase power, enabling the operation of larger machinery in buildings where three-phase power is unavailable. But not all rotary phase converters are alike; correspondingly, knowing how they differ may help equip you with the means to select an appropriate converter. This article goes on to describe types of rotary phase converters, along with their features, benefits, and applications. The guide will assist commercial enterprises, technicians, or do-it-yourselfers in making an informed decision and enhancing operational efficiency.

What is a Rotary Phase Converter and How Does It Work?

A rotary-phase converter is a device that converts single-phase electrical power into another simpler form of three-phase power, which is needed for operating industrial machinery and other similar equipment. It acts on a single-phase current with a three-phase motor (called an idler motor), which generates the third phase required from the single-phase supply. The converter balances and disperses this power evenly so that any three-phase equipment could run efficiently from a single-phase power source. This characteristic makes rotary-phase converters suitable in areas where three-phase power is not readily available.

How Does a Rotary Phase Converter Generate Three-Phase Power?

A rotary phase converter, on the other hand, generates three-phase power by means of an idler motor producing a rotating magnetic field. Single-phase input power is supplied to the idler motor. The motor comprises windings and capacitors that have been engineered so as to generate the missing third-phase condition. As soon as the motor starts turning, it actually induces the generation of the third phase through electromagnetic means, thereby generating balanced three-phase power output.

Since the converter balances the voltage and current along all three poles of the power output, the more advanced converters use digital controls and devices for voltage regulation. This will ensure that the output remains stable and well within standard deviations of three-phase voltages, typically ±5% from balanced voltage levels. Such precision rotary phase converters can, therefore, run sensitive three-phase machinery such as CNC machines, pumps, and compressors with no great risk of power fluctuations causing damage to the equipment.

Efficiency-wise, a rotary phase converter is dependent upon the quality of components utilized and how well it has been matched to the power requirements of the equipment in need of three-phase power. Modern converters can get up to 95% in efficiency and beyond, which makes them a fine and cost-effective alternative to the installation of a dedicated three-phase power infrastructure.

Key Components of a Rotary Converter

Each rotary phase converter consists of several essential components that work together in perfect harmony to transform single-phase power into three-phase power effectively. Here are the main components and their functions:

- Idler Motor

The idler is the heart of a rotary phase converter; it is generally an induction motor. While spinning, it produces the third phase. The idler motor creates this third phase to provide the necessary electrical balance. Modern idler motors have an energy-efficient and long-lasting design for long-term use with consistent performance.

- Start Circuit

This circuit starts the idler motor with capacitors or relays. This amplifies the starting torque to overcome static friction, giving the motor a smooth start. From advanced designs, automatic controls evolve for an optimal start.

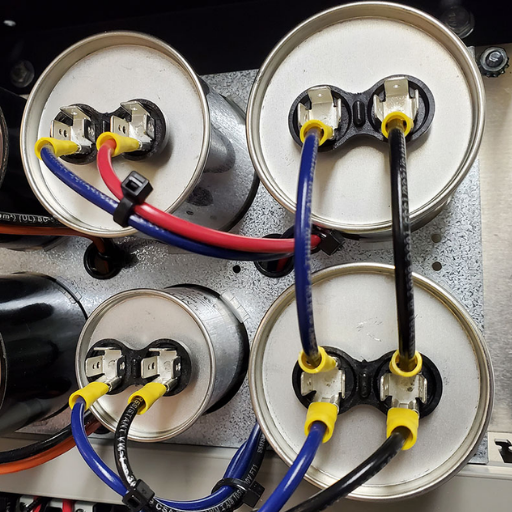

- Run Capacitors

Run capacitors are provided for balancing the voltage and to have a steady output. The run capacitors are also used to adjust the generated phase so that the sensitive equipment will be allowed to have a proper voltage match. This matches perfectly with rotary converters for diverse industrial applications.

- Control Panel

The control panel includes the basic electronics and all automation required to operate the converter. It contains overload protection, on/off switches, and user control systems to ensure user safety and system reliability. It is common for modern panels to have programmable features to allow the user to adapt performance.

- Output Terminals

At these terminals, the output, three-phase power, connects to the equipment. The best terminals provide a firm connection to transmission with little or no power loss.

- Frame and Cooling System

The frame takes all its components and protects them from external damage. Cooling systems, plus design implementations like fans or ventilation, ensure the system does not overheat while operating under heavy load.

These components are utilized in a rotary phase converter with proper design to provide smooth and reliable power, which reduces operational disruptions and increases the productivity of an industry.

Benefits of Using a Rotary Phase Converter

- Cost-Effective Solution

A rotary phase converter lets industries use three-phase equipment with a single-phase power supply, thereby eliminating the need for costly utility infrastructure for three-phase power. Consequently, this results in lapses both in terms of upfront and long-term costs.

- Versatility

Rotary phase converters enjoy high versatility, being capable of powering almost every brand of three-phase equipment, including motors, pumps, compressors, and CNC machines. This flexibility enables a wide range of businesses across the manufacturing, agriculture, and woodworking sectors.

- Reliable Performance

By nature of their construction, rotary phase converters provide a rich, unbalanced three-phase power that works well and helps prevent equipment from wearing out. Because of their reliability, downtime and expensive repairs are all minimized.

- Efficient Power Conversion

The latest rotary phase converters are designed with high-level conversion efficiency, with few able to give a power balance within ±2%. This feature ensures efficient working of sensitive machining while effectively utilizing the available power.

- Improved Equipment Longevity

Balanced and stable power provided by a rotary phase converter protects equipment from damage caused by voltage fluctuations and one-sided power distribution, thus prolonging equipment life and reducing maintenance activities.

- Ease of Installation and Use

Rotary phase converters are constructed for easy and quick installation that requires very minor to no alteration in the existing system. Also, maintenance is very easy due to their simple control interface, from which operations can be controlled conveniently.

- Scalability

The converters can be customized or upgraded to deal with power increases, giving the business a scalable solution.

- Low Maintenance Requirements

Such phase converters have long-life elements and require just nominal maintenance, hence saving customers’ money for maintenance in the long run. Most modern designs are created with long-term use in mind and have operational downtimes reduced.

It is the above benefits that have made rotary phase converters an invaluable piece of equipment to industries requiring power solutions that are efficient, cheap, and reliable.

Exploring the Main Types of Phase Converters

- Rotary Phase Converters

It is a rather effective method of generating three-phase power from single-phase power. These are best suited for attention requiring a common, unbalanced power output or machinery and equipment requiring a power supply in workshops.

- Static Phase Converters

Static phase converters are simple and cheap, in principle. These are also best for light applications or equipment that does not require three-phase power continually.

- Digital Phase Converters

For precision, digital phase converters employ an advanced electronic interface to control phase conversion. Highly efficient and balanced power is supplied through these means, and hence suitable for sensitive and high-demanding equipment.

Differences Between Static Phase Converter and Rotary Converter

Selling-pointing static-phase converters against rotary-phase converters is to consider their functionality, efficiency, usage, and expense to make the apt choice for a particular need.

- Functionality

The static phase converter uses capacitors to generate a third phase of power when starting the load. After starting the equipment, the converter ceases to develop the third phase of power so that the machine runs on two phases only. This makes it perfect for equipment requiring reduced power for operation, such as motor-driven equipment with light loads.

Rotary converters, on the other hand, continuously maintain a balanced third phase by using a three-phase motor referred to as the idler motor. This ensures that equipment under medium or high loads or tools needing steady performance enjoy balanced three-phase power.

- Efficiency

Static converters are not efficient when operating under continuous large loads because after the start, the load depends on the other two phases. This will degrade performance and increase wear on certain equipment. Rotary converters, on the other hand, conserve efficiency in high-power applications since they provide balanced and continuous power, which subsequently protects the motor, allowing it to work smoothly.

- Application

Rotary converters are very versatile and are suitable for practically any form of industrial machinery, such as milling, lathing, or CNC, which relies on uninterrupted three-phase power. Static converters, however, are more limited and find their use in simpler types of equipment, primarily where the need for start-up oriented assistance on, say, small pumps or fans, is paramount.

- Cost

Static converters attract less initial capital than rotary units, hence rendering them attractive for smaller requirements. Rotary converters, however, are more costly but warrant an increased reliability vis-à-vis ease of maintenance and laying down of wear on larger operations.

The main decision revolves around meeting specific operational demands, the type of equipment, and the budget. Wherever heavy and industrial applications arise, the rotary converter is proposed; meanwhile, wherever an occasional-use machine or light operations are needed, a static converter has been preferred.

Understanding Digital Rotary Phase Converters

Digital rotary phase converters are an example of an important evolutionary step in phase conversion, combining the traditional rotary mechanism concept with modern digital controls. The converters employ microprocessor-based systems to balance voltages accurately, resulting in improved performance and efficiency in powering three-phase machinery. Digital-type rotary phase converters can adapt to load changes on the fly to deliver steady power output, minimizing effects on the machine from overloading or surges.

This industry trend points out that digital rotary phase converters are very energy-efficient and can go up to 98% energy conversion efficiency. These aspects make it an eco-friendly option for industries that require energy cost cuts. Plus, with sophisticated diagnostic and monitoring methods, operators can monitor performance metrics from the digital rotary phase converter and foresee any pending problems. Being able to provide power to energy-hungry machines, such as CNC machines, lathes, and heavy-duty compressors, obviously gives these a cutting-edge reputation in marginally fresh manufacturing and production plants.

Choosing the Right Type of Phase Converter for Your Needs

Digital rotary phase converters mark the next transformation of phase conversion technology when classical rotary methods are merged with modern digital controls. They apply microprocessor-based balance of voltage systems to provide better power to reduce inefficiencies of three-phase machinery. Unlike in the case of conventional rotary phase converters, the figure of conversion can be determined in real-time, the varying load to keep power very steady, minimizing the risk of overheating or power surges.

Phase conversion is necessary for certain types of equipment because they are designed to run on three-phase power, which is a more stable and efficient energy supply as opposed to a single-phase supply. However, in certain areas, there is only a one-phase power supply. In such a case, phase converters ensure the gap is bridged such that any equipment runs as designed for best output, wear, and lifetime. This is especially needed in heavy machinery, HVAC systems, and industrial tools, which demand the steadiness and might of a three-phase system on their own.

Why Do Types of Equipment Require Phase Conversion?

All types of equipment require phase conversion because they run on three-phase power, which is a more stable and efficient energy supply as compared to single-phase power. However, in some areas, only single-phase power is available. Phase conversion equipment helps equip machinery to perform as intended with full performance, less wear, and more life expectancy. This, in turn, is important for heavy machinery, HVAC systems, and industrial tools that need the consistency and power of a three-phase system.

Industrial Applications of Three-Phase Power

In every industry, power generation is important. In the industrial sector, the generation and supply of three-phase electricity is better than single-phase power in terms of efficiency, reliability, and performance. An exhaustive list of major industrial applications, along with the role of three-phase power in each, is given below:

- Manufacturing Equipment

-

- CNC Machines: Three-phase power CNC machinery to ensure precision during cutting, milling, and drilling operations in industries.

- Robotic Arms: Three-phase power is stable, ensuring an uninterrupted power supply needed by robotic systems on an assembly line for smooth operation.

- HVAC Systems

-

- Industrial-Grade Air Conditioning Units: For large-scale cooling in factories and data centers, three-phase power is essential for proper operation.

- Heating and Ventilation: High-capacity heating and ventilation systems operate on three-phase current, thereby assuring temperature control at all times.

- Electric Motors

-

- Pumps and Compressors: Powerful pumps, compressors, and blowers run from churning water to refining oil with three-phase power, with little vibration and greater efficiency.

- Conveyor Belts: The industrial conveyors used in mines and production plants operate smoothly, thanks to the consistent torque, which is provided by the three-phase motors.

- Power-Intensive Tooling

-

- Welders and Plasma Cutters: Three-phase power is essential to delivering high-quality welding and precision cutting in metalworking applications.

- Grinding and Lathe Machines: This heavy-grade tooling equipment used for shaping materials thrives on a stable energy supply.

- Renewable Energy Systems

-

- Wind Turbines: Most three-phase systems enable wind energy installations to convert electricity from wind energy.

- Hydroelectric Generators: For a steady supply of energy to the grid, hydropower plants employ three-phase electrical generation.

Data on Efficiency

- Energy Efficiency: Three-phase motors are about 25 to 30% more efficient compared to single-phase motors carrying the same loads, thereby making considerable contributions to energy savings in industrial applications.

- Cost-Effectiveness: An up-to-20-percent decrease in operational costs owing to lowered wear and tear on machines and maintenance requirements is reported from the industrial perspective for three-phase systems throughout the equipment’s lifetime.

- Power Reliability: Since the one and only power load is always balanced in a three-phase system, the power dips or surges are minimized, delivering reliable and constant power to critical applications.

Creating stable and powerful electrical supplies, three-phase power is indispensable for modern industries and guarantees effectiveness, savings, and operational consistency. This advanced power system thus supports the growing needs of industrial and technological development.

Role of Phase Converters in CNC Machinery

Phase converters are critical in enabling CNC machinery to operate efficiently in environments where a three-phase power supply is not readily available. The converters turn single-phase power into three-phase power so that CNC machines can handle high-performance requirements that necessitate consistent and balanced power for precise operations.

Typically, with a rotary phase converter, an idler motor is used to generate that third line of power and generate a balanced three-phase output. For example, rotary phase converters can hold voltage imbalances well within 2-5%, which is the point of system stability. Such accuracy means that complex CNC operations remain precise with no interruption due to power imbalance.

Static phase converters work for simpler machines or light-duty operations. While they are cheap to maintain, static converters usually rarely provide full horsepower requirements that CNC machinery would call for, thereby making them on the undesirable end of the spectrum for heavier applications.

Another one-the-fly solution is a digital phase converter that employs microcontroller-based control to constructively monitor and adjust power output with near-perfect voltage control, a great benefit to CNC component life and tight machining tolerances.

Correct phase converter investment leads to a more efficient production line, decreases downtime, and improves the life span of the CNC gear. Analysis suggests that with well-implemented phase conversion systems, companies see maintenance costs lesser by 15%-25% and reduced delays in production, underscoring phase conversion’s importance in the modern-day workflow system.

Voltage and Power Supply Considerations

When selecting a phase converter for CNC machinery, understanding voltage compatibility and power supply requirements is crucial. CNC systems typically demand stable and precise power delivery to ensure accurate operations and avoid disruptions. For instance, most CNC machines operate efficiently within a voltage tolerance of ±5%, making voltage regulation a key priority.

Fluctuations in power supply can lead to overheating, mechanical wear, and inaccurate machining, which compromises productivity. Studies indicate that high-quality phase converters equipped with voltage balancing capabilities can mitigate voltage dips or spikes, ensuring a consistent energy flow. Furthermore, CNC machines might require significant startup power, often 2-3 times higher than their running power. A properly sized phase converter can accommodate these demands seamlessly, supporting operational stability.

Ensuring that the phase converter matches the equipment’s rated input voltage and phase type (single-phase or three-phase) will optimize machinery performance and extend equipment longevity. Adopting phase converters with integrated voltage monitors and overload protection features further enhances reliability, ensuring smooth operations even under varying load conditions.*

Static vs Rotary Phase Converters: Which is Better?

If the dynamic and static-type rotary phase converters agree on any point, it will be that such an option will depend on the special application and power requirements of your equipment:

- Small, single-motor uses that do not require full power capacity are best served by Static Phase Converters. They cost less because they are simpler to install, and they deliver only a fraction of the motor’s rated power. Hence, the performance of heavy-duty tasks may simply be inadequate.

- Rotary Phase Converters are more versatile and more efficiently used to supply power to machines that manufacturing or industrial applications. Consistent operational full power is delivered.

For most applications requiring reliable, continuous, and high-capacity power, rotary phase converters are generally the better choice.

Pros and Cons of Static Phase Converters

Pros

- Cost-Effective: Static phase converters are generally more affordable than rotary phase converters, making them a budget-friendly choice for small-scale or occasional use.

- Simple Installation: These converters are easy to install, requiring minimal setup, which is ideal for less technical environments.

- Compact Design: Their smaller size and lightweight design make them easy to integrate into existing systems without significant space requirements.

- Efficient for Single-Purpose Machines: Static phase converters work well for machines that do not require continuous full power, such as occasional use lathes, mills, or drills.

Cons

- Limited Power Output: Static phase converters furnish only about 50-70% of the rated power of the motors, possibly limiting their performance in heavy-duty applications.

- Compatibility Issues: They really are not suitable for multiple machines or equipment having varying power needs, as they are tuned for a single dedicated machine.

- Restricted Industrial Use: They may not be fit for long-running or heavy industrial jobs where constant full power is required.

- Risk of Motor Overheating: Because of this, their power efficiency is lowered, and more heat tends to be generated, which can, in the long term, affect motor performance and life.

Having these pros and cons enables you to make better decisions in choosing a static-phase converter for your specific situations. Operational requirements, power demand, and frequency of use should be evaluated in determining whether this choice works for you.

Advantages of Rotary Phase Converters Over Static Options

- Superior Power Quality

Rotary converters produce a true three-phase power output with a voltage and frequency very close to that of utility-grade electrical power. This gives smoother operation to three-phase equipment, and vibrations are reduced, along with wear and tear due to uneven power delivery.

- Higher Load Capacity

Rotary converters can handle motor loads that are heavier and varied, including loads with high starting requirements that static converters are incapable of managing. This can be put to use in CNC machines, pumps, compressors, etc.

- Continuous Operation

While the static-type converters are suitable intermittent converters for short-time operation, rotary phase converters are designed for continuous operation and thus can reliably sustain power for equipment running through extended periods without interruptions.

- Versatile Applications

Due to their versatility, one rotary phase converter can power more than one machine at the same time. This is a flexible solution, especially when you have varied equipment in workshops, factories, and agricultural settings.

- Improved Efficiency

The rotary phase converter design provides a consistent power output, which increases the efficiency of the equipment connected to it. It will also minimize the possibilities of overheating or underperformance as compared to the static ones.

- Durability and Longevity

With fewer electronics components and a sturdy mechanical design, the rotary phase converter usually has a longer life with lesser maintenance, hence reducing long-term operational costs.

- Support for Larger Motors

Adversely to static converters, rotary converters effectively handle powering large three-phase motors that are far too large for static phase converters and hence guarantee adequate performance for demanding industrial activities.

The rotary phase converters serve as a tall order to the complexity of power needs over a wide-ranging arena of industries by manipulating its advantages.

When to Choose Static vs Rotary for Your Application

Whether to choose between static and rotary phase converters depends on your exact needs, intended application, and budgetary considerations. Here is a detailed overview of various situations in which one or the other is preferable:

When to Choose Static Phase Converters

- Light to Moderate Load Applications

Static converters work best for small, single-motor equipment that does not demand continuous heavy-duty work. This generally refers to tools or machines having vanishing low starting torque requirements: drill presses, table saws, some fans, to name a few.

- Cost-Effective Solution

If the economy rules, static phase converters are definitely worth the choice for converting single-phase power to three-phase. They entail less upfront expense than a rotary converter.

- Ease of Installation

Because of their very simple design and diminutive size, static converters have few steps in the installation process. This makes them a popular choice for a quick retrofit or some temporary use.

- Energy-Efficient for Intermittent Use

Static converters are highly efficient energy-wise for machinery or equipment that operates in a start/stop fashion, rather than solidly operating at full power. They drain very little energy when left standing idle.

When to Choose Rotary Phase Converters

- High Torque and Heavy Load Applications

Rotary converters are used for high torque applications or occasionally for running more than one three-phase motor in parallel. Industries that require dynamic technologies, such as CNC machines, compressors, and pumps, benefit from such a robust and stable power supply.

- Consistent Voltage Balancing

Where voltages very need to be very stable for sensitive equipment, rotary converters offer consistent and truly balanced three-phase power so that the sensitive equipment can work very efficiently without damage.

- Long-Term Durability

Rotary just means that these are phase converters built to last, so they stand out as the right type for continuous and heavy-duty operations. Their ability to last overrides the upfront cost any day long.

- Versatility Across Multiple Machines

If you are dealing with many machines or pieces of equipment with varying power requirements, then rotary converters can intermittently provide for them all from a single unit.

- Scalable and Industrial Grade

Large industrial operations that require much power are served well by rotary converters, as the capacity may be set higher to handle bigger loads.

Summary Table of Key Considerations

|

Factor |

Static Phase Converter |

Rotary Phase Converter |

|---|---|---|

|

Best For |

Light loads, single motor |

Heavy loads, multiple motors |

|

Initial Cost |

Lower |

Higher |

|

Voltage Stability |

Moderate |

Excellent |

|

Installation |

Simple and quick |

Requires professional setup |

|

Durability |

Moderate |

High |

|

Power Requirements |

Intermittent use |

Continuous, demanding use |

By considering your operational priorities and keeping these considerations in mind, the best phase converter can be selected for your unique power requirements, efficiently and sustainably.

How Do Phase Converters Work with Different Types of Equipment?

Different types of phase converters use different processes for producing single-phase to three-phase conversion. Rotary converters produce the most balanced and stable power, making them best for heavy machine tools such as CNC or lathe machines. Static converters can be used for saws or drills, where full three-phase power is not required continuously. Digital converters are the most exact and can support a wide variety of sensitive or high-demand equipment, such as medical devices or complicated industrial systems. One decides on the basis of power need and operational demands.

Impact on Three-Phase Motors and Generators

Superior efficiency and dependability characterize three-phase motors and generators when utilizing a stable three-phase power source. Phase converters are indispensable in rendering these machines fully functional, especially where three-phase power is unavailable. Rotary phase converters would provide not only balanced, high-quality three-phase power but also an environment with low electrical noise, indirectly preserving the lifespan of a motor or generator.

Research indicates that these motors run 50% more efficiently than single-phase motors, hence their preference in the industrial world. These motors produce smoother torque, which results in lower vibrations and allows manufacturers to operate their machinery with greater precision. Whereas generators operating on three-phase generation systems have a superior capacity for power generation and can give a higher voltage output, conversely, they undergo more power loss in transmission over long distances.

Given proper implementation of phase converters, power fluctuations will be kept away from the internals of the windings of the motor, which can lead to either sudden overheating or accelerated wearing. This results in longevity, less maintenance, and eventual economic benefits for companies that depend on such equipment.

Ensuring Voltage Balance in Three-Phase Equipment

Thus, voltage balance is an important condition to maintain for the performance and longevity of three-phase equipment. The imbalance may generate excessive heat, less efficient operation, and require greater energy to work. Strategies and considerations that must be applied in balancing the voltage include:

- Monitoring Equipment Regularly

Using advanced monitoring systems, such as voltage and current analyzers, allows for the real-time diagnosis of a three-phase system. Any late detection of faults will incur greater costs of damage. This means it is recommended that a voltage imbalance be kept below 1% at all times to avoid operational inefficiencies.

- Properly Sized Conductors and Connections

An incorrect configuration, undersized conductors, or the presence of loose connections within a system could present voltage drops and imbalances across phases. Proper conductor sizing and tight connections minimize the possibility of imbalanced loads.

- Load Balancing Across Phases

Unbalanced loads are the major factor contributing to voltage imbalance. Equipping and installing machinery and appliances in a way that loads equally over all three phases makes a big difference in keeping variations to a minimum, e.g., industrial systems aim to have loads balanced to within 10% per phase.

- Utilization of Phase Balancers and Voltage Regulators

Automatic phase balancers or voltage regulators can continuously compensate and correct imbalances on a real-time basis. Since these advanced devices incorporate prediction technology, they react half a step ahead of load fluctuation and safeguard the optimal health of a system.

- Periodic Maintenance of Transformers and Motors

Aging transformers, deteriorating motor windings, or poorer connections might cause irregular voltages. Such equipment should be routinely inspected and replaced to ensure its reliability of the equipment.

- Relevant Data and Industry Standards

Standards indicate that minor imbalances in voltages of only about 2% may increase motor temperature by approximately 15-20% according to the National Electrical Manufacturers Association (NEMA), hence its faster wear and shorter life. Sticking to such standards helps businesses avoid unnecessary downtimes and standardize the life utilization of their equipment.

These methods and techniques, together with the associated recommended practices, enable energy optimization in relation to the work being performed, thereby increasing workmanship reliability and promoting unforeseen repairs so as to ensure long and stable operations in the three-phase system.

Understanding the Importance of Selecting the Right Phase Converter Motor

Selecting the right phase converter motor is imperative to achieve optimum performance and ensure smooth functioning of three-phase systems. Phase converters are utilized to convert single-phase power to three-phase power so that industrial-grade machinery can work efficiently without having access to a typical three-phase power grid.

Consider horsepower, the type of load your equipment will handle, and operating efficiency when making selections. Recent developments have established rotary phase converters as among the most dependable and versatile. Generally, these converters can keep voltage balance within 2% to 5%, which reduces wastage of energy and, subsequently, improves efficiency and longevity of equipment. Another technical aspect is dynamic load capacity, with over-sizing of converters generally recommended by manufacturers for heavy-duty machinery so as not to compromise performance under varying operating demands.

The industry claims that a system with a properly sized converter can achieve up to a 30% increase in energy efficiency as compared to excess or undersized motors. The phase converter in the market with built-in surge protection and advanced control boards also protects your sensitive equipment against fluctuation in power, thereby reducing the chances of such equipment getting damaged or going down.

By following through with a realization of power demands and then implementing the latest innovations in phase conversion, a business is capable of maximizing production and reducing long-term operational costs. Helping to boost performance, such decisions then ensure practically different applications with varying smooth workflows and reliability.

Reference Sources

- Rotary Converters – Google Books – A detailed exploration of rotary converters, their operation, and commercial applications.

- Rotary converters versus motor generators – IET Digital Library – A comparative analysis of rotary converters and motor generators, discussing their advantages and types.

- A rotary converter – IET Digital Library – An in-depth examination of rotary converter experiments and their operational characteristics.

4.Top Rotary Frequency Converter Suppliers In China

Frequently Asked Questions (FAQs)

Q: What are the two main types of rotary phase converters?

A: The two main types of rotary phase converters are static phase converters and rotary phase converters. Static phase converters can start 3-phase motors but are not suitable for continuous use, while rotary phase converters are used to convert single-phase electricity into three-phase power, providing continuous and balanced 3-phase power.

Q: How does a rotary phase converter work?

A: A rotary phase converter works by using an idler motor to generate a third line of electric power, which, when combined with single-phase electricity, produces 3-phase power. The idler motor creates a rotating magnetic field, generating a sine wave that is 120 degrees out of phase with the existing single-phase power.

Q: What should I consider when choosing a phase converter?

A: When choosing a phase converter, consider the type of equipment you are using, the power requirements, and the load type. Ensure the converter can handle the inrush current and has appropriate phase converter sizing for your 3-phase motor needs. Additionally, factors such as power factor and the specific applications, like CNC equipment, should be considered.

Q: Why are rotary phase converters preferred for CNC equipment?

A: Rotary phase converters are preferred for CNC equipment because they provide balanced three-phase power, essential for the precise operation of such equipment. They maintain the necessary voltage stability and frequency to ensure smooth and accurate performance.

Q: What is the difference between single-phase power and 3-phase power?

A: Single-phase power consists of a single alternating current cycle and is typically used in residential applications. In contrast, 3-phase power consists of three alternating current cycles that are 120 degrees out of phase with each other, providing a more constant and efficient power supply suitable for industrial and commercial applications.

Q: How do American rotary phase converters enhance electric power?

A: American rotary phase converters enhance electric power by converting single-phase electricity into balanced three-phase power. They are known for their reliability and efficiency, ensuring consistent power delivery to heavy-duty industrial equipment, including traction motors and CNC equipment.

Q: What is the role of a synchronous phase converter?

A: A synchronous phase converter is used to convert single-phase electricity into three-phase power, similar to other rotary phase converters. It operates with a synchronous motor to maintain a high power factor and efficiency, suitable for applications requiring precise electrical characteristics.

Q: Can a rotary phase converter be used to operate a frequency converter?

A: Yes, a rotary phase converter can be used to operate a frequency converter (VFD). The rotary phase converter provides the necessary 3-phase power, allowing the VFD to control motor speed and frequency, making it versatile for various industrial applications.

Q: Why is the 120-degree phase difference important in three-phase power systems?

A: The 120-degree phase difference in three-phase power systems is crucial because it provides a continuous and balanced power flow, reducing power pulsations and ensuring smoother operation of 3-phase motors. This balance is essential for applications demanding stable and reliable electric power.