It is imperative for everyone involved in the field of electricity or working with devices to understand the concept of rated voltage. Whether you are a seasoned professional or just a regular inquisitive student, rated voltage is essential for achieving safe and efficient operation of the equipment. But the term rated voltage itself. How important is it exactly, and what are the reasons? The power of this text is to create the concept in fewer and simpler words, and also by dividing it according to its literal, operational, and practical sides. Moreover, the use of rated voltage as a tool for differentiation in the market will be discussed. This post is a must-read for those who want to obtain a better understanding of the rated voltage and discover its importance in the world of electricity.

Introduction to Voltage

Voltage, also known as electric potential difference, is the force that propels the electric current through the circuit. The measurement of the force is in volts, and it also represents the potential energy of each charge unit between two points in an electric system. Voltage is the factor that enables the flow of electric current. If there is no voltage, there will definitely be no current—and if there is no current, the electric equipment will not work either. Knowing and easily understanding this fundamental idea is crucial for rating the voltage of any equipment or system, even if you lack technical knowledge about it.

Definition of Voltage

Voltage is one of the basics of operational effectiveness and safety in electrical systems. It represents the energy of electrical charges and directly and indirectly regulates the behaviour of electrical devices. Commonly, in the United States, the household circuit is of 120 volts, whereas in many European countries, it is 230 volts. This difference in voltage shows how the voltage standards might vary, thus indirectly affecting the design of electronic appliances. Apart from that, knowledge about voltage is indispensable for activities related to renewable energy systems, where regulating voltage levels is key to achieving effective energy utilization and storage. Voltage usage will always be considered, whether for low-voltage circuits in electronic devices or high-voltage lines transferring electricity over long distances. Voltage, as a metric and essential element, will never be off the list of fields for engineers or technicians working in various industries.

Importance of Understanding Voltage Ratings

It is indisputable that to ascertain both the safety and energy-saving performance of power systems, one has to be fully aware of voltage ratings. The voltage ratings are the maximum voltage levels of a device, wire, or system that can be safely connected. If the ratings are exceeded, the system risks overheating, equipment malfunctions, or even a catastrophe like a fire due to short-circuiting. This information is essential for industries in the new technologies field, with the most common being electric cars and renewable energy systems. They require the highest standards of voltage management to get an optimized performance and prolonged life. The battery advancements are a good example of this; the energy output and the service life of the battery are in balance through strict control of voltage levels. Furthermore, electricians and engineers are compelled to obtain voltage rating data to adhere to safety standards and regulations, thereby ensuring reliable operation and reducing hazards in everyday and industrial locations.

Overview of Types of Voltage

| Type of Voltage | Description | Key Points |

|---|---|---|

| Direct Current (DC) | Flows in one direction only. | Stable, used in batteries and electronics. |

| Alternating Current (AC) | Periodically reverses direction. | Standard for homes and industries. |

| Low Voltage | Typically below 50 volts. | Safe, used in lighting and devices. |

| High Voltage | Above 1000 volts (AC) or 1500 volts (DC). | Required for power transmission. |

| Extra Low Voltage (ELV) | Less than 50 volts. | Common in communication systems. |

| Extra High Voltage (EHV) | Exceeds 345 kV. | For long-distance power lines. |

| Constant Voltage | Voltage remains steady over time. | Ensures stability in circuits. |

| Variable Voltage | Voltage adjusts or fluctuates. | Used in variable-speed applications. |

Rated Voltage Explained

Rated voltage is the highest possible voltage at which a device, system, or component is expected to work without any danger in normal circumstances. The producer provides this figure and serves as a guide on how to improve quality, life, and safety. Overloading a device beyond its rated voltage can result in excessive heat, destruction, or malfunction. The essential requirement is to adhere to the rated voltage limits to maintain the efficiency and reliability of electrical systems at the desired level.

What is Rated Voltage?

Rated voltage is a crucial factor in ensuring the safe and effective operation of electrical devices and systems. It defines the perfect voltage range for the device’s operation without fear of inefficiency or damage. For example, household appliances typically have standard electrical grid system rated voltages of 120V or 240V, depending on the region.

The performance and lifespan of equipment can very much be affected by going beyond or dropping below the rated voltage. Being below the voltage rating may cause the equipment to operate inefficiently, while being above the rating can result in heating, insulation failure, or even complete device failure. In addition, devices or systems with parts handling voltages that are consistently not within the rated capacity range can be expected to wear out more quickly, leading to increased maintenance costs and possible safety hazards.

The awareness and adherence to the rated voltage specifications help customers reduce energy usage, minimize operation costs, and, at the same time, make electrical systems more reliable in the long run. The mentioned factors collectively establish the rated voltage as a core element of the entire electrical infrastructure design and operation.

Difference Between Rated Voltage and Operating Voltage

| Parameter | Rated Voltage | Operating Voltage |

|---|---|---|

| Definition | The maximum voltage that equipment is designed for | Voltage equipment operates at during use |

| Purpose | Ensures performance reliability | Reflects real-world usage conditions |

| Safety Margin | Includes a safety limit | May vary within the safety range |

| Variability | Fixed and predefined | Subject to fluctuations |

| Determined By | Manufacturer specifications | Actual system conditions |

| Compliance | Ensures standard compliance | Depends on operational situations |

| Impact on Lifespan | Protects equipment durability | Overload can reduce lifespan |

| Energy Efficiency | Optimized for design parameters | Depends on system load |

| Measurement | Rated under controlled testing | Measured during operation |

Rated Voltage vs. Nominal Voltage

| Key Point | Rated Voltage | Nominal Voltage |

|---|---|---|

| Definition | Standard operating voltage | Expected operating range |

| Stability | Fixed and constant | May vary slightly |

| System Design Basis | Equipment design specification | Variable depending on system |

| Importance | Ensures safe operation | Reflects typical usage |

| Testing Conditions | Controlled environment | Real-world conditions |

| Unit Consistency | Always precise | Subject to adjustments |

| Purpose | Evaluates device limits | Defines practical operation |

| Voltage Tolerance | Narrow tolerance range | Broader tolerance range |

| Application Field | Equipment manufacturing | Power distribution systems |

| Safety Margin | Includes safety margin | May not include buffer |

Understanding Operating Voltage

The operating voltage is the range of voltages under which a machine or system can effectively and safely operate under normal conditions. The equipment’s specifications define it, and it is also influenced by the materials, usage, and safety. Managing the voltage is crucial to prevent mishandling the device, which may lead to overheating or destruction. Remember that the manufacturer’s manual is the ultimate reference, and an operator should be on the safe side.

Definition of Operating Voltage

It is of the utmost importance for the correct and reliable operation, as well as the lifespan, of electrical and electronic equipment to understand the operating voltage. Using a device outside the recommended voltage range can lead to safety issues, performance drop, or even total damage to the device. High voltage can cause overheating, short circuiting, or insulation breakdown. Low voltage may cause erratic behavior or a lack of power, preventing the system from operating correctly. Moreover, today’s equipment usually comes with specific voltage tolerances to cope with minor voltage changes. Thus, it is imperative to abide by the specified voltage range by the manufacturers. Proper knowledge of operating voltage not only protects the equipment but also impacts environmental protection and is essential for adherence to safety standards in both residential and industrial applications.

How Operating Voltage Relates to Rated Voltage

The relationship between operating voltage and rated voltage is critical to the performance of electrical systems that are both safe and efficient. The rated voltage is the highest voltage that a device or a component should be exposed to in everyday use. This point is a good practice for preventing the device from burning out, making it a technical safety consideration for manufacturers in their product selection process and for users when they install it. On the other side, the operating voltage is the voltage level at which the device functions, often depending on environmental conditions, load, and power supply quality.

For instance, in domestic environments, many household appliances are designed for a voltage rating of 120V or 240V, reflecting the typical voltage supply in the countries where they are sold. Nevertheless, due to the power grid’s instability, the operational voltage might differ slightly from the rated voltage without affecting the device’s performance, provided it remains within the manufacturer’s indicated tolerance band. Correspondingly, in the area of industry, transformers and machinery are adjusted precisely to ensure voltage compatibility with the rated voltage, achieving both energy efficiency and a longer lifespan.

Applications of Operating Voltage in Electrical Equipment

Home Appliances

Household appliances like refrigerators (120V in the USA, 230V in most European countries), washing machines, and microwaves are being limited to specific voltage ranges to ensure correct operation and energy savings. Performance degradation, shorter lifetime, or even a high-temperature burnout are some of the consequences of working with machines outside these limits.

Industrial Machinery

It is typical for industrial motors, conveyor systems, and manufacturing tools to require specific voltage levels—usually between 400V and 600V, which ultimately depends on the geographical area. Electricity is to be the one that machines respond to as a result of the continuous balance of voltage and current.

Lighting Systems

For stabilization and preservation of light, LED lights, fluorescent lamps, and streetlights must operate at a regulated voltage. As an example, the most common LED (Light Emitting Diode) lights found in household systems are engineered to work on 120V or 230V. Still, the higher voltages of 277V or more may be required for high-intensity lighting in outdoor areas.

Medical Equipment

Precise voltage levels between 110V and 240V, depending on the equipment design, are usually required for diagnostic instruments like MRI machines, X-ray systems, and patient monitors. The setting of voltage is imperative both for the patient’s safety and for the accuracy of the instrument.

Electric Vehicles (EVs)

EV batteries and charging systems typically run on high voltages, ranging from 400V to 800V. Accurate voltage regulation is essential for fast charging, extending battery life, and ensuring safety for both the vehicle and its user.

Power Distribution Systems

The operations of the transformers and substations occur within specific voltage ranges, which in turn adjust the high or low voltages for transmission and distribution purposes. For instance, high-voltage transmission lines are primarily used to transfer produced power, often running at 110kV or even higher in voltage. The low-voltage distribution systems deliver energy directly to consumers’ homes and offices, and they can be either 230V or 120V.

Voltage Ratings in Electrical Equipment

The significance of voltage ratings lies in their ability to guarantee the equipment’s safe and efficient operation. The maximum voltage that the equipment can bear without getting damaged or endangering safety is indicated by these ratings. Following the voltage ratings as specified helps prevent events such as overheating, electrical shorts, or equipment failures, which, in turn, prolong the life of the device. An instance of not following this is the 120V-rated appliance, which should not be connected to a higher voltage system because it could lead to electrical malfunctions or fires. The manufacturers derive these ratings from particular tests to reach both safety and performance standards; therefore, one should consider it a duty not to operate the equipment beyond its specified range.

Importance of Voltage Ratings for Safety

Understanding and interpreting the voltage ratings is a crucial factor in ensuring safety in electrical systems. There are voltage limits that the devices or appliances are designed to work with, and if these limits are exceeded, there is a possibility of fire, shock, or equipment damage. It is a fact that, concerning the home environment, electric power failures and circuits account for at least 13% of reported home fires. This fact also indicates a need for voltages to adhere to normal capacity levels. However, the protection has never been limited to just that; in fact, there are many other ways equipment can be damaged, even if they have not been properly grounded. Still, voltage rating must always be a priority. There is a real and absolute need for it to be done, and people are gradually recognizing the enormous benefits that are attached.

Maximum Rated Voltage Considerations

It is a critical consideration when taking the maximum rated voltage into account that the manufacturers’ operational limits should be respected to ensure the good performance of electrical equipment that is also reliable and safe. Failure to comply with these limits will make the equipment more vulnerable to overheating, breaking, and becoming a source of electric shocks. As an example, the materials used for insulation are designed to withstand particular voltage levels. And any attempt to use them to exceed those levels may result in a short circuit through insulation breakdown. Besides that, new findings assert that many energy-saving appliances operate only within certain voltage levels, making their use entirely dependent on the power supply’s compatibility. Correct identification and compliance with the maximum rated voltage not only prolongs the life of the equipment but also leads to more efficient energy use and greater system stability.

Voltage Ratings in Transformers

Voltage ratings are crucial in transformers, and they affect the performance, reliability, and safety of the transformer. The range of voltage at which a transformer is designed to operate is divided into two categories, known as the primary and secondary rated voltages. The figures for these two voltages set limits on the possible change in input voltage, which, if exceeded, may cause insulation failure, overheating, or loss of efficiency.

The transformation of the overall energy sector has led to changes aimed at increasing the efficiency of transformers, making them smarter in terms of voltage control and losses. One of the most practical applications is weathering the periods when the power generated from renewable sources does not match the load in terms of both electricity and power quality. An example is that step-up transformers used in solar and wind energy systems must efficiently change the low-voltage input from renewable sources to suitable levels for grid distribution.

In pursuit of serving these intricate requirements, it has become common practice in transformer manufacturing to use the most advanced insulation materials, the most accurate winding techniques, and the most sophisticated cooling systems. Achieving voltage ratings is a pivotal factor not only for functionality but also for safety standard compliance and reducing the failure risk of the equipment. Being familiar with these problems and the improvements allows the industries to put on the market transformers that are both tough and power-efficient.

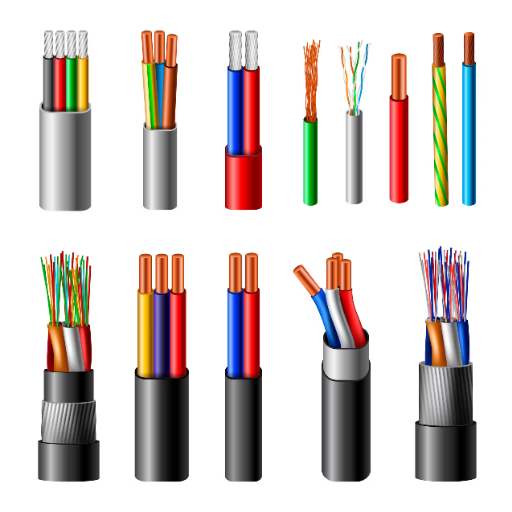

Types of Cables and Their Voltage Ratings

Cables are grouped according to their voltage ability and usage, a process that makes power transmission safe and efficient. The cables listed below are just a few of the needs with their respective voltage ratings:

Low Voltage (LV) Cables

For systems running at up to 1,000 V, cables are frequently installed in homes and shops.

Medium Voltage (MV) Cables

These cables are designed to operate at voltages from the line to 35kV and are often found in industrial and utility power network projects.

High Voltage (HV) Cables

These cables are used to connect substations and electrical grids on a large scale to power transmission systems, operating between 35kV and 230kV.

Extra-High Voltage (EHV) Cables

At voltages higher than 230kV, these cables are the backbone of the long-distance power transmission system and are designed to handle significant power sources.

It is all about the voltage level and the operating application when deciding on the cable type to ensure both safe and powerful operation.

Common Types of Cable Voltage Ratings

| Voltage Rating | Voltage Range | Key Features | Applications |

|---|---|---|---|

| Low Voltage (LV) Cables | 0 – 1kV | Safe for residential and commercial use | Homes, offices, small industries |

| Medium Voltage (MV) Cables | 1kV – 35kV | High insulation for moderate energy transfer | Utilities, industrial plants |

| High Voltage (HV) Cables | 35kV – 230kV | Designed for large-scale power distribution | Substations, urban grids |

| Extra-High Voltage (EHV) Cables | Above 230kV | Engineered to transmit power over long ranges | Large grids, cross-country transmission |

| Ultra-High Voltage (UHV) Cables | Above 800kV | Handles ultra-heavy energy loads | Specialized national power grids |

Choosing the Right Cable Based on Voltage Rating

When choosing a cable with the correct voltage rating, several critical considerations are involved to ensure good performance and safety. When it comes to low-voltage applications like house wiring or light commercial requirements, LV cables are suitable because they are designed for moderate energy transfer. Medium voltage, commonly seen in industrial plants and utilities, involves MV cables that provide a solution to high power demand.

High voltage cables have different ranges from 35kV to 230kV for urban grids and substations. These are places where large-scale power distribution is needed. In larger applications and longer distances, extra-high voltage cables with ratings above 230kV are the best for the job and the most economical for the energy transfer in the grid. And if an even more energy-intensive scenario is to be dealt with, for example, national power grid systems for a very substantial energy flow, then ultra-high voltage cables could be the logical choice (UHV), being used as a prime example.

Thus, by identifying the necessary voltage rating level for any application one aims to cater to, selecting the correct type of cable ensures proper energy transfer and adherence to system requirements. The latest developments in cable technology further boost the strength and performance of these high-load systems, therefore, meeting the modern infrastructure demands.

Voltage Differences in Cable Applications

The dissimilarities in voltage play a crucial part in determining how the cable is made and whether it will work. Low-voltage cables, which are primarily utilized in home wiring and in small industries, can handle up to 1,000 Volts. These cables are usually insulated with materials like PVC or XLPE to ensure safety and save energy. Medium-voltage cables, which go up to the range of 35,000 Volts, are used primarily for industrial purposes and urban power distribution. In extreme cases where the input or output voltage exceeds 35,000 Volts, such as in power transmission over long distances, specially designed conductors with strong insulation and high-quality shielding are needed to reduce loss and ensure high reliability.

The use of a cable is determined not only by the range of the voltages it carries but also by the current, environmental conditions, and thermal behavior. A good example is when high-voltage cables incorporate the best technology features, such as gas-injected insulation and a metallic sheath, which effectively reduce effects like partial discharge and enhance longevity. The installation of renewable energy units like solar and wind farms has, in many cases, increased the demand for highly versatile cable systems that accommodate fluctuating power while remaining efficient. With knowledge of these voltage disparities and their consequences, engineers can choose the most suitable cable type, which will maximize the system’s performance improvement and durability.

Reference Sources

Limitations of HVAC offshore cables in large-scale offshore wind farm applications

Summary: This study explores the limitations of high-voltage alternating current (HVAC) cables in offshore wind farms. It includes simulations of a 220kV air-insulated single-circuit single-pole transmission line.

Cost-effective smart metering system for the power consumption analysis of households

Summary: This paper discusses a smart metering system designed for analyzing household power consumption. It highlights the importance of aligning the mean value of AC voltage with the operating voltage in the analog-to-digital (AD) converter.

Frequently Asked Questions (FAQs)

What is Rated Voltage in Electrical Equipment?

The term “rated voltage” refers to the maximum voltage at which electrical equipment can be used without issues. It is also referred to as the system’s nominal voltage, a level of voltage assigned to an electrical device under standard operating conditions. For example, a transformer may have a rated voltage of 11 kV, which means it is built to withstand that voltage safely. It is hence essential to know the rated voltage so as to prevent voltage drop problems and keep the system voltage stabilized during operation. For instance, the rated voltage of a cable ensures it can draw power as expected and not overheat or fail miserably.

How Does Rated Voltage Differ from Nominal Voltage?

The terms rated voltage and nominal voltage are often mistakenly thought to be the same, although there are slight differences to be made. The rated voltage indicates the maximum voltage a piece of equipment can safely handle, while the nominal voltage is specified as the voltage used in the general view of an electrical system. As an instance, a cable marked with a rated voltage might not have a nominal voltage that differs from the rating, thus operating effectively under typical conditions. To the engineers and technicians, this distinction is crucial during the system design phase, as they must consider power and voltage ratings to the maximum to prevent equipment failure.

What is the Maximum Rated Voltage for Transformers?

The maximum rated voltage of transformers is the highest level of voltage they can work at without being damaged. This voltage is crucial to ensure that any transformer using it operates safely, efficiently, and within its proper limits. For example, a transformer may have a maximum rated voltage of 33 kV. It means the transformer has the ability to withstand the voltage up to that level without any problem. Moreover, an increase in voltage may result in the breakdown of insulation, overheating, and even a severe failure of the system. Therefore, during the selection of the transformer, it is of paramount importance to consider this maximum voltage to ensure it aligns with the system voltage.

What is the Voltage Rating of Cables?

The voltage categorization of the cables is the top electric potential that the cable can bear without any safety hazard. This category is essential to avoid overheating and possible electrical breakdown. For example, the 600-volt-rated cable is mostly seen in house wiring scenarios, whereas ultra-high-voltage-rated cables can operate at very high levels. The required voltage for a specific application is the output of electrical energy needed, and selecting a cable with the appropriately rated voltage is crucial. Moreover, the cable, together with its accessories, must be rated to ensure the safety and reliability of the whole system.