The phase converter is among the essential equipment in the electrical systems field, offering an unconventional solution to converting single-phase power to three-phase power. Such a tech-savvy helper is a big boon for industries not equipped with three-phase power. The problem of insufficient three-phase power supply is tremendously eased by the use of phase conversion technology, which was adapted for a broad range of applications, including hobbyist and workshop use. Reaping the benefits of industrial machinery that runs smoothly and stays reliable over time, requires one to be analytical in the case of selecting the right frequency in using phase converters, and each type of the machine and its use is a different factor. Understanding the nature of electrical impedances in a load is the first step before choosing phase converters. Meanwhile, new and existing installations prefer to rewire electric motors instead of installing phase converters.

Overview of Phase Conversion

Phase conversion is the process where electrical power gets changed from one phase configuration into another, most often from a single-phase power to a three-phase power. Such conversion can be done with the help of dedicated equipment, called phase converters. For most residential and remote locations, single-phase power is the usual option, but electricity-intensive equipment used in industries and commercial sites need three-phase power to run at their best. This is where phase converters come in: they make it possible to power three-phase equipment through normal wiring without the necessity of expensive utility upgrades for users and businesses. Three types of phase converters mainly dominate the market: rotary, static, and digital, each being functional for different purposes and offering different levels of efficiency and flexibility.

Definition of Phase Converter

A phase converter is a device of electrical nature and if enters into the process it creates a 3-phase electrical output. The three-phase machinery and equipment can be operated if the three-phase power supply is replaced by a single-phase power supply in the areas where only single-phase power supply is provided. So this is a must in situations where you need a three-phase power supply to operate motors, pumps, compressors, and other industrial or commercial machines that are in need of more power and have higher efficiency requirements. The recent era has seen significant developments in the field of phase converter technologies leading to increased reliability, energy efficiency, and precise voltage balancing with the help of digital phase converters especially, being a no exception. These are the systems using highly advanced electronic components to deliver power that is both steady and adaptable in nature, thus ensuring optimal performance for sensitive equipment. Furthermore, the choice of the right phase converter includes the consideration of factors like load type, horsepower requirements, and compatibility with the existing electrical systems so as to make the operational efficiency efficient as per the waste of energy.

Importance of Phase Conversion

The phase conversion is a crucial process that makes it possible for the three-phase power systems to be used efficiently and effectively in a single-phase power environment. A lot of industrial machines and equipment, like CNC machines, compressors, and pumps, need the power of three phases in terms of efficiency and reliability for their correct operation. If there is no phase conversion, it may be very expensive to change to a utility connection with three phases i.e., the economic cost may make it impossible to do so especially in rural or remote areas.

New phase converters, especially rotary and digital ones, have made remarkable progress in terms of efficiency and accuracy. As an example, digital phase converters use solid-state electronics to create a third phase with high precision. This technological improvement helps to significantly lower power variations and downtime, which are critical for environments with very high performance tolerances. Energy studies have shown that proper use of phase conversion systems can significantly cut down power loss that is not really needed, thus ultimately reducing operating costs.

Applications of Single-Phase to Three-Phase Conversion

- Industrial Machinery

For optimal performance, many industrial machines, such as lathes, milling machines, and CNC equipment, require the power generated from three-phase. The superior torque and smooth output that three-phase motors give make way for the precision and reliability of the machine. According to estimates, three-phase motors consume about 10-15% less energy than the motors operating on the three-phase system and, consequently, the savings over time will be substantial.

- HVAC Systems

Heating, ventilation, and air conditioning systems in large buildings rely on the stability that three-phase power supplies. For example, maintenance cost reduction in three-phase compressor and pump operation is great; availability flexibility is considerable and staff service is greater. A lot of three-phase HVAC systems can actually be 25% more energy-efficient than single-phase systems in their specific environments, which is a huge difference.

- Renewable Energy Systems

Renewable energy technologies like wind turbines, solar inverters, and others, mostly employ three-phase power to manage energy distribution in an effective way. The conversion enables single-phase installations like residential solar systems to have access to high-capacity three-phase grids and produce steady energy. At the same time, it also makes such a system scalable for future energy demands.

- Agricultural Equipment

The use of three-phase power enhances the operation of three-phase supplies of modern agricultural equipment, irrigation pumps, and grain dryers, which work with more energy than single-phase. For the case of remote farms that are usually served by single-phase but require three-phase power, one of the same phase conversion systems will reduce the need for expensive infrastructure upgrades and still provide continuity for critical equipment operation.

- Workshops and Small Industries

Many small manufacturing units and shops need three-phase tools and machines like welding equipment, and air compressors. The use of phase conversion will also become the reason for fewer or no utility lines to be drawn which needs three-phase power and so will reduce the cost and at the same time be more economical for the smaller operations.

- Electric Vehicle (EV) Charging

When it comes to charging stations for electric vehicles, high-powered EV chargers use three-phase systems to charge the car battery as quickly as possible. Moreover, the conversion of the single-phase input to the three-phase power will enable the residential or the commercial setup to cater to the rapid EV charging demand that is increasing by the day without having to change the entire electrical system.

Key Types of Phase Converters

- Static Phase Converters

These are some very good devices for setting up three-phase motors without spending too much money. The downside is that they are only able to provide three-phase power during the motor startup operation and then they revert to operating with a single phase, which in some cases can have an impact on the motor’s efficiency and power.

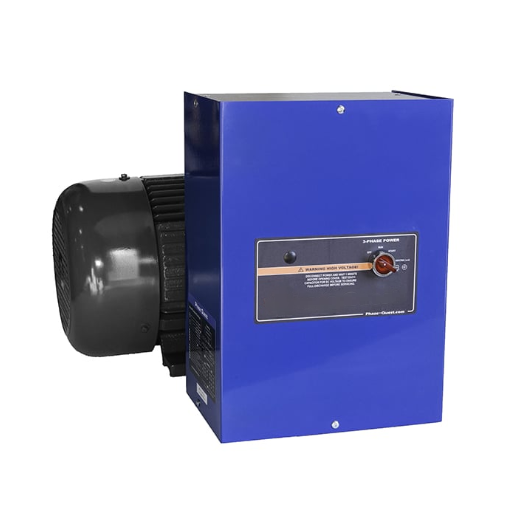

- Rotary Phase Converters

A rotary phase converter is based on a specially designed motor-generator that delivers permanent three-phase power. Nowadays, they are used for really frequent running of three-phase machines, like multiple units or heavy-duty ones, which is why they have found their place in the industrial and commercial sectors.

- Digital Phase Converters

Digital phase converters are also known as phase inverters, as these equipments are transforming single-phase to three-phase and they do it efficiently and effectively. These systems are characterized by high reliability and versatility and can be considered as a power source for the most demanding applications or circumstances in which power fluctuations are a concern.

Static Phase Converters

Static converters provide a cost-effective solution for converting single-phase power into three-phase power. They work by delivering an initial blast of power to start three-phase motors, after which the motor runs on single-phase power. Though they are less complicated in configuration and mostly less costly compared to rotary or digital phase converters, their performance is very much down to earth and suited for the cases when the load is kept constant. Static converters are the best choice for when the system requires only light or medium-duty operations, such as woodworking machines or small pumps. Besides, they are not advised for the tool needing continuous full three-phase power since this may cause some of the parts to work improperly because of the undelivered power. Nevertheless, innovation of static phase converters has improved their reliability and compatibility, but it is still very important to use the converter that matches the motor and application capabilities.

Rotary Phase Converters

Rotary phase converters are efficient and highly effective when it comes to granting three-phase power equipment with the help of single-phase power supply. Therefore, when compared to static converters, rotary phase converters, in general, have an additional feature accompanying a rotating motor generator to indeed have a three-phase output. These converters will have to be connected to every load and even the entire bus to get the work done.

New technologies have been introduced focused on the efficiency improvement, noise reduction, and adaptability of the rotary phase converters. The modern and innovative digital controls have eased the real-time monitoring and adjusting facilities, ensuring the improved performance and extended life of the connected equipments. Furthermore, when we compare to other systems, rotary phase converters generally offer higher starting capacities, which is the reason why they are suited for applications with very frequent starts or stops or changing load requirements. Moreover, for scaling up power needs, many of the models provide an option for adding modular units, which makes them a great fit for the evolving facilities to be put in HTML terms.

Digital Phase Converters

Digital phase converters are a much better and more accurate alternative for changing single-phase power to three-phase power. They are able to make dynamic monitoring and adjustments of electrical output due to being made with semiconductors and controlled by microprocessors to the end that voltage balance and frequency are kept in a constant and continuous way. For the most part, the digital converters are ideal for the sensitive equipment or devices such as CNC machines and other recent industrial applications as they are not tolerant of small imbalances in voltage that can take place and thus lower efficiency or even damage the equipment.

Compared to rotary phase converters, digital converters have no moving parts spinning around, which makes maintenance needs and the noise caused by operation drop drastically. Not only that, but digital converters are also better at saving electricity by providing needed power to the machinery that is on. Nowadays, advanced digital converters embody a bunch of functions such as live diagnostics, customizable output configurations, and compatibility with any outside monitoring system, which helps users optimize performance and minimize shutdowns.

How Phase Converters Work

Converters are electrical devices that are applicable for converting a single-phase electrical power source into a three-phase power supply. This feature is necessary for the smooth running of three-phase power-supported equipment in the absence of a three-phase power line in the area. This method can be achieved using one of the three main techniques: rotary, static, or digital conversion. Through the employment of a motor-driven system, rotary phase converters get the three-phase output on a balanced level. However, the static converters do carry out their job by making the equipment start with a simulated third phase and then keep on operating the single-phase supply. On the other hand, digital phase converters use very sophisticated electronics to create very precise and stable three-phase electrical energy. Depending on the application, each of these methods has its dominant role in the market, with digital models as the most efficient and flexible for modern systems handling.

Mechanics of Phase Converter Operation

Phase converters work by adjusting electrical energy in order to mimic or create the necessary phases for the three-phase machinery. In the case of rotary phase converters, the single-phase input gets to run through the motor rotation originating in the generator power being changed to three-phase. This process requires producing a magnetic field that rotates to replicate the absent phases. On the other hand, using capacitance for creating a third phase momentarily during startup and then running the equipment on single-phase power is the principle that the static phase converters depend upon. This method, however, restricts the performance and is usually not suitable for heavy-duty or variable load cases.

Phase converters that are digital, of course, can create three-phase power and the like by drawing on insulated-gate bipolar transistors (IGBTs) and the like and are interweaving with micro-controlling. These set-ups take active measurements of the voltage and the current and the like in order to deliver the three-phases so that the resultant total is smooth and presents little harmonic distortion. The technology has sought adaptability as a core attribute and industrial machinery as well as modern applications have become the two main usage areas. Besides that, the high energy efficiency of digital converters makes them generally the better choice for high precision environments and for facilities that give energy conservation priority.

Understanding Rotary Converter Functionality

Rotary converters are electromechanical devices that are made to change electrical energy from one form to another, mostly to change single-phase power into three-phase power for the industrial sector. The rotation segment dominates most of the systems. The stator, rotor, and exciter windings make up the majority of the rotary converters. The stator initiates the magnetic field and the rotor assists in the transfer of the electrical energy into mechanical motion or vice versa. Exciter windings work by regulating the magnetic flux and thus ensuring that the output is always the same. It is this uniformity of the generated power enabled by the rotary converters that matter most in the functioning of machines that are very heavy and hence need precise phase sync and load control.

The very large power loads they are able to handle and their very low sensitivity to power surges make rotary converters extremely important in environments where durability and resilience are required, not to mention that they have become a firmly established product in such environments. In addition, and also very important, is the fact that modern rotary converters come with integrated advanced monitoring systems, meaning that it is possible to get the real-time data of the performance indices like power efficiency, phase balance, and thermal output. This checks that maintenance can be time-expected leading to a decrease in the breakdown time and hence the life of both converter and the equipment can be extended.

Static vs. Digital Phase Converter Workings

| Feature | Static Phase Converter | Digital Phase Converter |

|---|---|---|

| Power Output | Limited to startup only | Continuous power to load |

| Application | Primarily for light-duty machines | Suitable for heavy-duty equipment |

| Efficiency | Lower operational efficiency | Higher operational efficiency |

| Phase Balance | Poor phase balance | Excellent phase balance |

| Maintenance Requirements | Minimal but limited functionality | Advanced monitoring, proactive upkeep |

| Initial Cost | Lower cost | Higher upfront investment |

| Scalability | Limited scalability | High scalability in power needs |

| Longevity | Shorter lifespan | Extended lifespan of system |

| Adaptability to Load Changes | Less adaptable | Highly adaptable |

| Noise Level | Typically louder | Quieter operation |

Factors to Consider Before Purchasing a Phase Converter

- Power Requirements

Evaluate the individual power requirements of your equipment. Verify if the total horsepower and voltage of your machinery correspond to the ratings of the phase converter.

- Type of Equipment

Check if your equipment is affected by phase imbalances. Precision machinery could be a good candidate for rotary converters because of their steady and balanced performance.

- Budget

Don’t forget the initial capital expenditure and the costs of maintenance along the life cycle. With a static converter, you might spend less money in the beginning, though still with a reduced range of applications; on the other hand, rotary converters will normally give more value for the money even with higher starting costs.

- Scalability Needs

Think about the possibility of power growth within your setup. Rotary converters are going to be the best choice for businesses that anticipate the need of a substantial increase in power; static converters will close the door for such future requirements.

- Installation Space

Measure the available room for the converter in your site. Make sure there is sufficient space, especially for larger rotary phase converters, which are larger than the static phase converters.

- Noise Levels

For operations where the noise level is of concern, rotary converters are the preferred option due to their lower than static converters noise levels which is important in places that are very sensitive about noise.

Assessing Power Requirements

It is crucial to take the time to figure out how much power is necessary when looking for phase converters to use. One of the simplest ways to do this is by calculating the total power (HP) of all the machines that will be operational simultaneously. In this way, you will not exceed the limit, and the converter will be able to handle the load. Moreover, determine the voltage your appliances need as well because an incorrect voltage can either lead to poor performance or equipment damage.

It is also necessary to include the starting current of equipment with high power, such as, for instance, motors, compressors, or CNC machines, which, by the way, usually demand considerably more energy while being started. This starting current is also called inrush current and it may require a converter with a higher capacity than the steady-state load could suggest. Furthermore, the duty cycle of the equipment is another factor one should consider when deciding on the converter, whether the converter can actually support the operation during long or repeated periods is what might still be the case.

Budget Considerations

Evaluating power converter budget constraints, it is important to consider not only efficiency but also the investment part of it. The price reduction of converters may be appealing at first but in the long run they are likely to malfunction due to inefficiency, weak protection against lightening induced breakdowns or poor quality of material. Thus, high maintenance costs or shorter service life could be the consequence. One of the efficient ways to go green is by paying more for an Energy Star certified model which will also save a considerable amount of electricity cost in the long run. Detailed planning is key to the continuous provision of sufficient power to meet inevitably increasing demands over time. Moving along the chain of mentioned factors, you will soon manage both expenses and feel safe by getting such equipment for a longer period of business.

Compatibility with Existing Equipment

It is of utmost importance to be certain that when choosing a converter or equivalent equipment, they are fully compatible with the current systems so that the efficiency is not affected and to prevent any harm from happening. The best way to start is by examining the input and output details of the converter to make sure that they fit with the power requirements and the voltage levels of the present set-up. For example, verify that the unit works on the same frequency and is single-phase or three-phase like the system in use.

In addition to this, the question of the industry standards and the communication protocols should be taken into consideration, e.g., Modbus, CAN, or Ethernet since different protocols can be a source of trouble in making systems integrate with each other and exchanging data among them. To this end, the acquisition of manufacturers’ technical literature and compatibility tables can be of great help and serve as the most reliable source of information for the elimination of these risks. Through a thorough evaluation, you will guarantee the smooth integration and permanent operational safety of your installation’s infrastructure.

Maintenance Tips for Phase Converters

- Regular Cleaning

Maintain cleanliness for the dust, garbage, and humidity; Use the dry mop or slightly wet mop to wipe out the surfaces and keep the right air circulation.

- Inspect Connections

Look at the electrical connections repeatedly; If you see any signs of wear and corrosion, or if they are loose, tighten or replace them if necessary so that malfunctions will be lessened.

- Monitor the Cooling System

Watch out for the cooling fans or vents to be well. Prevent over heating and maintain efficiency by just having a right cooling mechanism in place.

- Check for Wear and Tear

Check the spindle bearings, capacitors, and other things inside for evidence of wear and damage at regular intervals. If anything looks bad, change it right away so that the system does not fail.

- Test Voltage Outputs

Looking at the voltage output from time to time is good for ensuring that it is within the manufacturer’s specification. You know that the adjustments or repairs are needed if there are any changes.

- Follow Manufacturer Guidelines

See the maintenance plan and advices in the manufacturer’s guide and do your best to prevent the loss of guarantees and maintain the performance.

Common Issues and Troubleshooting

- Overheating

Overheating is one of the most common issues in electrical systems and it is often caused by a heavy load or bad ventilation. In that case, the solution is to make sure all components are working in the temperature range; and also fans or heat sinks, if they are the cooling mechanisms, are dust-free and in good condition. Contemplate using thermal monitoring tools for active temperature monitoring.

- Power Fluctuations

Voltage spikes can cause damage to the sensitive equipment or can stop the ongoing process altogether. Such a situation may be related to unstable grid power or the equipment itself, like capacitors. The solution is to plug in surge protectors or uninterruptible power supplies (UPS) devices to get the voltage regulated. In the same way, one should also check the wires and circuit breakers every month to figure out the source of the problem.

- Connection Failures

One common issue that arises due to loose or corroded connections is the pale light and poor system operations. This issue can be alleviated through regularly cleaning and greasing connectors, applying of corrosion inhibitors, and making sure all the connections have the specified torque applied to them.

- Component Wear and Tear

Gradually during time, both physically and electrically parts get degraded and this can cause the operation of the unit to be different or even no operation. First symptoms of the damage are strange noises, power fluctuations, or visible wear and tear. Make a decision about high-usage parts to be changed on a regular basis and carry out very precise and complete checks to ensure that the unit does not break down soon.

- Software Malfunctions in Automated Systems

One of the modern systems’ pitfalls is that they rely heavily on software integration. The software might be buggy, the firmware may be old and, hence, incompatible updates can cause the entire system to malfunction. The main steps for avoiding the above are: regular software updates based on the manufacturer’s recommendations and default checking of the system’s health through software tools specifically designed for diagnostics.

Ensuring Longevity and Efficiency

Systems depend on software, bugs, and incompatible updates lead to software malfunctions but bugs in the system’s software could be the least intimidating one. The failures of automated systems due to software malfunctions is the devolvement of any system and it that case it is a one that could result in a the of writes or power the, in addition to the updating of the software, the running of a regular diagnostic program which can only be done by, and the manufacturer’s advices should be followed, is a must.

Efficient energy use is a possible result of the systems calibrated properly and the usage of energy recovery facilities, like the heat exchangers or some sophisticated power supply management protocols that channel the extra energy back to the operation cycle. Keeping an eye on the system parameters and saving the respective data in logs, like temperature, pressure, and energy transmitted, could also provide useful data for process professionals. Last but not least, the trend in the sector with respect to the introduction of innovative ideas and uniform standards is a prerequisite situation for adapting to the future project that is, at the same time, safe for the system from being modified.

Reference Sources

- Enhancing Power Conversion Robustness: A Novel Approach Using Topologically Protected Circuits in DC-DC Converters

Link to source - Teaching Switching Converter Design Using Problem-Based Learning with Simulation of Characterization Modeling

Link to source

Frequently Asked Questions (FAQs)

What is a phase converter, and how does phase conversion work?

A phase converter is a type of machine that permits machines intended for three-phase energy to be powered by a single-phase energy source by synthesizing the absent phase(s). Consequently, enabling three-phase equipment to work with one phase as an entry is executed in various ways where the most common are rotary generation, electronic switching, or digital control that are able to produce even three-phase power. Popular types consist of rotary phase converter, static phase converter, and digital phase converter and they also have an impact on power quality and power factor in different ways. Comprehending the connection from single to three phase is a fundamental part of the decision-making process regarding which type of converter should be chosen for the purpose, either solid-state phase converter or rotary converter.

How does a rotary phase converter create 3-phase power from single-phase?

Rotary phase power is provided to the electronic devices with the help of the idler motor that spins electrically to produce the third leg of power which starts running the three-phase motor. This way is very common and gives stable power to three-phase motors whereas the motor power is properly dimensioned, they can provide utility power to the three-phase system. Rotary phase converter can be operated with a control panel or supplied with as an option in some applications to increase the phase balance, and quality of the power. Rotary converters are found to be much more capable than the static ones as it is a general case with them that they support saving power and usually they facilitate power factor correction for the three-phase equipment, as well.

What are the types of phase converters and types of phase converters available?

Rotary phase converters, static phase converters, and digital rotary or electronic phase converters are the main kinds of phase converters. While static phase converter designs may be the simplest or cheapest, these configurations cannot guarantee maximum power supply for a continuous three-phase motor. Despite that, digital rotary phase converter and solid-state phase converters are still available with an edge in terms of phase balancing. By using VFDs, variable frequency drives, and digital solutions one can also convert the single phase to three phase with motor speed control and efficiency improvements thus, the choice of the phase technologies that a user will adopt very depending on the desired power quality, cost, and whether control panel integration for complex systems is required.

Can you convert a single-phase motor to 3-phase?

Yes, it is possible to change single-phase power into three-phase power for operating three phase motors by means of a phase converter, VFD or digital rotary phase converter, depending on the motor’s starting and running requirements. Typically, three-phase motors require matched and well-controlled three-phase power plus sufficiently high starting torque, hence rotary or VFDs are best for large motors while small ones may be able to use static converters. The motor’s long-term performance is affected by such factors as power factor, utility power quality, and control panel features. For the sake of precision, drives and digital phase converters or VFDs are better than just basic static solutions control wise and protection wise in addition.