Quietly working in the background and providing the necessary balance in terms of power, frequency converters are one of the many incredible technological advancements of modern-day electrical systems and industry. Supporting both angles of achieving better efficiencies from equipment or making two or more power systems function harmoniously, these apparatuses have become prominent in various sectors. Nevertheless, choose a resolution regarding the type of equipment, say, static or rotary, which will favor smooth operation and cost reduction among many. The article aims to elucidate the fundamental differences between static and rotary frequency converters, including how they work, standard designs, and their respective advantages. Finally, one will be able to identify the cases where each is preferable, and the alteration of such techniques will enhance the performance of the provided systems.

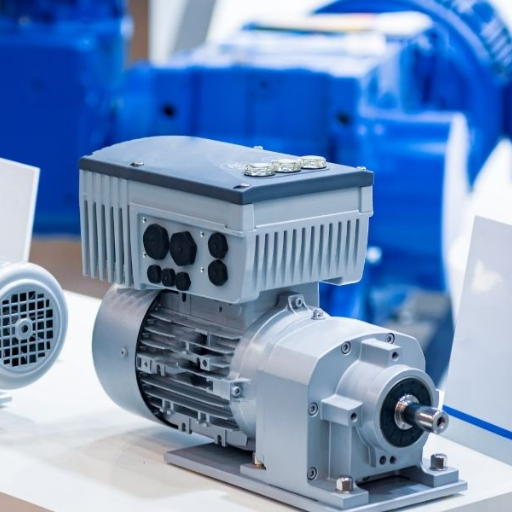

How Does a Static Frequency Converter Work?

A static frequency converter helps alter the AC frequency from the input to obtain a different frequency at the output. No mechanical components are involved in this process. The process is broken down into three significant steps: electrical conversion, reversal conversion, and frequency conversion. To begin with, the single-phase or three-phase AC is changed to DC utilizing rectification. After that, it is turned back with the help of a single-phase or three-phase inverter, but at a different frequency. Finally, the final form of the output is adjusted to the required parameters. The resulting mechanism has tremendous efficiency and reliability, as there are no machine members; therefore, there will not be a wear and tear issue, and last but not least, less servicing is needed due to the lack of moving parts. A static frequency converter is most frequently applied in areas where the ability to control a specific frequency is required, such as aviation, ground, surface military applications, and manufacturing processes.

What is a Static Converter?

This static converter transforms electricity from one form to another in a very compact design without mechanical movement. Design is generally based on or utilizes controlled semiconductor devices made of irreversible processes, such as diodes, transistors, thyristors, etc., which facilitate the conversion. Depending on the application requirements, static converters are expensive enough to include the components associated with voltage, current, and frequency transformation. For example, such systems are arranged to change the current from AC to DC or vice versa, or even change the frequency of the AC power supply into a particular frequency suitable for specific equipment. With the developments that have taken place in control and power engineering, current static converters are very efficient, and this is achieved without enlarging the size or causing moderate heat losses in such converters. These converters are also used in clean and green energy technologies, electric vehicles, industrial automation, and power grid stability.

The Role of Solid State Frequency in Static Converters

Solid-state frequency control is an indispensable component in the working and performance optimization of contemporary static converters. The advanced electromagnetic converters based on the modern technology of high-speed replacement devices like Insulated Gate Bipolar Transistors and Metal Oxide Semiconductor Field Effect Transistors allow the regulation of frequency with extreme precision and, hence, the adaptation to different applications with ease. Frequency control is significant for systems integration within the electric grid, where the correct operation amongst the different renewables demands a definite amount of energy flowing in and out of the system at all times. Further, in industrial automation, solid-state frequency devices improve speed and torque control of electric motors, thus increasing efficiency while keeping the machines from breaking down very quickly. Furthermore, using newer materials and efficient thermal management enables solid-state frequency systems to attain greater reliability and scalability, essential in environments with high demand for power applications, like electric cars’ powertrains and aerospace systems. Such progress enhances energy use efficiency and lessens the detrimental effects of present-day power systems on the environment.

Advantages of Static Frequency Converters

Static frequency converters is an indispensable component in the working and performance optimization of contemporary static converters. The advanced electromagnetic converters based on the modern technology of high-speed replacement devices like Insulated Gate Bipolar Transistors and Metal Oxide Semiconductor Field Effect Transistors allow the regulation of frequency with extreme precision and, hence, the adaptation to different applications with ease. The importance of frequency control is especially significant in systems integration within the electric grid, where the correct operation amongst the different renewables demands a definite amount of energy flowing in and out of the system at all times. Further, in industrial automation, solid-state frequency devices improve speed and torque control of electric motors, thus increasing efficiency while keeping the machines from breaking down very quickly. Furthermore, using newer materials and efficient thermal management enables solid-state frequency systems to attain greater reliability and scalability. This is important in environments with high demand for power applications, like electric cars’ powertrains and aerospace systems. Such progress enhances energy use efficiency and lessens the detrimental effects of present-day power systems on the environment.

Moreover, since SFCs make electric power conversion better transducers from one form to another, losses caused during this process are much less than those of rotating converters. This means less energy is used, and the operational expenses are favorable. Because of their small sizes and the fact that they have few moving parts, they can work for more extended periods without requiring frequent repairs, which leads to enhanced durability. In addition, unlike rotary frequency converters, they can incorporate wind turbines, thermal solar plants, and other renewable energy sources to make the general grid more efficient and sustainable.

These converters also support a wide range of input and output voltages, providing exceptional flexibility for diverse applications, from transportation systems to power supply stabilization in critical infrastructure. With advancements in digital control technologies and heat dissipation strategies, the latest developments in SFCs further optimize performance and reliability, catering to the demands of increasingly sophisticated electrical networks.

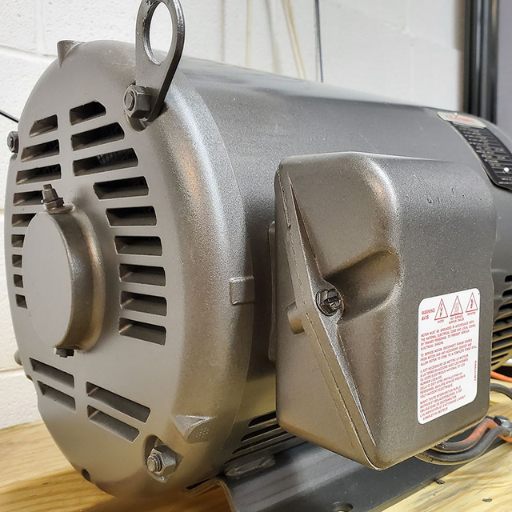

Exploring the Functionality of Rotary Frequency Converters

It is well known that rotary frequency converters are electromechanical devices that convert electrical power from one frequency to another using a machine in rotation. Such a device generally has a motor and a generator combined in a single unit with one shaft. The motor uses the incoming frequency to drive the generator, whose output is the required frequency. Such technology is preferred mainly because of its capacity to operate at high power, provide consistency of output, and facilitate various industrial and commercial processes that require a change of frequency. Rotary frequency converters are often used for aerospace, naval, and manufacturing applications where effective frequency conversion cannot be compromised.

What is a Rotary Converter?

This mechanical device contains an electric motor and a generator to convert electrical energy into another form. A rotary converter has one turning mechanism in which the input power is first connected to a motor section, and the output voltage or frequency is obtained by the generator section. Constant Phase Supply or Rotary Converters find usage when there is a need to change AC to DC electric power or vary the frequency of continuous voltage AC power supplied or controlled voltage AC power with or without conversion, which is a classic example of phase conversion, single to three-phase power conversion encountered in industrial machines. They are also effective where high power stability against loads is vital, as in some old military and industrial applications, and exceptional cases, such as aviation, railways, and defence. Such machines are durable, dependable, and can operate satisfactorily for lengthy periods even under severe conditions.

How Does a Rotary Phase Converter Operate?

A rotary phase converter uses a combination of mechanical and electrical systems to generate three-phase power from a single-phase source. At its core, the device consists of an idler motor, capacitors, and control components—the idler motor functions as the key element that produces the additional phase required for three-phase power. When single-phase power energizes the idler motor, it causes the rotor to spin, generating a rotating magnetic field. This rotating magnetic field, coupled with the capacitors, induces the creation of a third voltage leg, effectively simulating three-phase power.

Modern rotary phase converters are designed with advanced balancing techniques to ensure voltage output remains stable and consistent across all three phases, even under varying load conditions. This makes them highly reliable for operating diverse machinery that requires balanced three-phase power, such as CNC machines, lathes, and pumps. Precise control mechanisms and advanced monitoring systems enhance efficiency, reduce harmonic distortion, and improve overall performance.

Benefits of Using Rotary Frequency Converters

In my opinion, the use of rotary frequency converters has multiple advantages. These can provide a stable and well-balanced power supply that is very important for the smooth operation of any equipment without power fluctuations. They are made with tough construction materials, making them strong even in the most industrial applications. Also, the converters impede the harmonics, they are energy efficient, and come in handy under different load conditions, which makes them usable in various ways.

Static vs Rotary Phase Converter: Which is Better?

Deciding if a static phase converter or a rotary one is the optimal choice stems from analyzing their applications. For instance, static phase converters are advantageous in terms of cost and easy to implement. Yet, they are only considered when the machinery isn’t very valuable or a non-critical process. Of course, this may have a downside in a case where there is machinery for achieving various processes that necessarily require the provision of the total rated load.

In contrast, rotary phase converters can maintain relatively high and stable output power, recommending them for operating machines or equipment requiring heavy usage or precision, like CNC machines and industrial pumps. While increasing the cost and installation factors, these conditions do not limit their popularity since the units are known for their dependability. At the same time, they can handle loads of different levels and hence meet the demand for constant high-quality conditions of three-phase supply.

Key Differences Between Rotary and Static Converters

- Output Stability

Three-phase power produced by rotary converters is constantly and accurately balanced; thus, they are appropriate for supplying power to equipment that is sensitive or has high precision requirements, including numerical control machines and heavy-duty pumps. Static frequency converters, on the contrary, are not. Provide the equipment with uneven power, which may become dangerous in the long term, owing to its inefficiency or overheating.

- Ability to Adapt to Loads

Rotary transformers are very good at changing loads. They can cope with variation in the power requirement without any instability during different applications’ performance. On the other hand, static converters are meant for light-duty and steady apps where significant load fluctuation is acceptable and performance isn’t a factor.

- Ease of Use and Maintenance

Rotary frequency converters, like rotary machines, have more components and are hence more mechanical. This adds to their complexity; therefore, the dressing procedures are more cumbersome, and maintenance requires attention. However, they offer a simpler structure that can provide an energy supply with great functionality. Static converters are very basic in construction and rightfully so; they pose few problems in installation and maintenance, but they are more basic and restrictive in terms of what they can do.

- Economic Analysis

Rotary converters tend to have higher initial costs and installation fees due to their complex nature and incredible potency. Static inverters, being simple, offer an economical option suitable for small-scale or, simply stated, easy use.

- Effectiveness and where they are best utilized

Most people believe that rotary converters are more effective and should be employed for large-scale and industrial use, especially where a high-quality three-phase supply is needed. Static inverters are more suitable for fair-duty or straightforward equipment that doesn’t necessarily need such precision, since they are cheap and easy to use.

Which Converter is Suitable for Heavy Loads?

When choosing an appropriate Frequency Converter for large loads, critical considerations must be made. Rotary frequency converters, for instance, are designed to serve the needs of large loads. The converters can consistently serve the three-phase loads, thus ensuring a minimal voltage balance and attenuation. Some geared machines, such as lathes, mills, and rubber seals, require power supplies even when the load changes. Rotary converters can periodically consume energy from the system in large motors with complex electrical needs, preventing excess heating of the devices and maintaining such stability.

Static Frequency Converters have many disadvantages when dealing with massive loads compared to rotary phase converters. This is due to the devices’ cheapness and ease of installation. They can work only on machines that require a heavy inrush current at start-up, such as compressors during start-up. This way, it limits the connection to a machine that runs on low torques and does not fluctuate in demand for torque, thus the other balance is not utilised. In high-load or even variable-demand scenarios, the characteristics and capacity of rotary fittings are preferred.

Considering Moving Parts in Your Choice

When analyzing the inclusion of animate elements in a system designed for power conversion, consideration of their functional durability and maintenance requirements is indispensable. Systems incorporating moving elements, especially rotary phase conversion systems, will likely suffer wear and tear over time. Such moving parts might require timely checks, lubrication, and replacement of some components to enhance operative efficiency and system life. On the contrary, Static Frequency Converters, which are devoid of moving parts, present lower mechanical risks and maintenance challenges.

Nevertheless, all those regarding the intended purpose and operation must be understood. The rotary system performs very well because it has high power quality, which means that it can handle variable loads and torque better than other systems, thanks to its mechanical strength. The process of selecting a system must consider performance capabilities and available data on past levels of reliability to ensure that the chosen system is appropriate for the process and lifecycle for which the equipment is supposed to be used.

Understanding Three-Phase and Single-Phase Power in Converters

Static Frequency Converters and Rotary Frequency Converters are usually among the components needed in power control systems. Power level is directly related to RPM; the higher the number of RPMs, the simpler the control strategy. Conversely, single-phase systems discharge the power at reduced levels, such that inferential loads (for example, on objects supported from overhead structures) tend to obscure the circuitry. This tends to determine how high or low the levels of a converter need to be or would be in the linear power region.

How to Convert Single-Phase to Three-Phase Power

There is a solution for the conversion of single-phase power to three-phase power. I would use a phase converter, an option for such a case. There are three physically different types of phase converters, namely Static Frequency Converter, Rotary Frequency Converter, and Digital Phase Converter, that I can consider. The first type of phase converter that is cost-efficient and is used for light loads is a static converter, which has the power restriction to provide an improper output. The latter option is the rotary converter which is rather good because it can accommodate a relatively higher load for more efficient use and has a broad range of applications. The third option, the digital converter, guarantees efficiency and flawless results but with a higher price tag. I would check the machines’ power ratings and consider the environmental conditions before choosing the most suitable phase converter.

The Impact of Voltage and Frequency Conversion

Directly converting voltage and frequency affects how well the equipment performs, how efficiently, and how long it lasts. In my opinion, voltage regulation prevents the gadgets from working beyond the intended limits of operation, thus causing overheating and loss of performance. In the same breath, frequency conversion should be precise enough to allow such motors and other machines to rotate at constant speeds. And when I fit the proper conversion technique to the needs of my equipment, I would be able to achieve the best possible efficiency without critical wear or damage during the operation.

Role of Capacitors in Frequency Conversion

Reliance on frequency conversion on capacitors is due to their characteristic function as shock absorbers, maneuvering the noise in electrical signals, ultimately improving system efficiency. Such components ensure that high-frequency signals, where the carriers are mainly noise and interference, do not pass beyond the required frequencies. They are also responsible for adjusting the compensating reactive power, stabilizing the active energy against the inductive loads, and converting it. These days, high-k and better heat-resistant capacitors are used in industries. An example of their use is film and ceramic type capacitors because of their advantages, such as low levels of power loss and the capability to work at high frequencies. This is particularly the case in such systems as speed drives with variable frequency inverters, power inverters, or alternative energy sources, as such applications require stable frequencies and efficient systems. Hence, there is a need to know the various capacitors and when to use the,m since the accuracy and reliability of the frequency conversion in advanced devices depend greatly on them.

Choosing the Right Frequency Converter for Your Needs

You must first define the application requirements regarding source and output voltage, frequency, and power rating to get the best static frequency converter. Check if the converter is designed for the load type, which can be resistive, inductive, or capacitive, per the system requirements. Include power saving and dependability constraints on components available in the market when it involves processes dealing with alternative energy sources or manufacturing. Emphasize proper assembly converters built with advanced limitations, such as overcurrent protection, and appropriate to the current equipment, so there is no conflict and the equipment can be appropriately used even when the other equipment and the converter are replaced or repaired. The suggestion is provided to users not to settle with brands with poor reviews, as they will disappoint them in delivering their expectations in the long run, and the poor service is never enough to take care of the user’s needs. Alluded Rotary Frequency Converter made necessary references to the methodology with core usage of bought expressions.

Factors to Consider When Selecting a Converter

Selecting a converter involves understanding the technical capabilities of the component to use it most efficiently in one’s application. This is primarily because of input voltage and current, which the Static Frequency Converter must be able to feed to whichever system is being used without the components becoming unstable or damaged. The output voltage, current, and power ratings must also be set following the equipment connected so as not to damage or overload it or even use it inefficiently.

For many other applications, however, the converter’s efficiency is critical. Today’s efficient converters are built so that they tend to dissipate less power and produce less heat, hence removing the cost of operation, which is often very high in renewables or industrial geared systems. Note that the cooling function, coolers, or any heat management mechanisms must also be checked to sustain the given performance, continuous duty, or in case of high operation.

Ensure that you also consider the converter’s speed and performance. Some applications are particularly susceptible to changes in loads over a short duration. These advanced units come preinstalled with safety measures, including the famous over- and under-voltage and short-circuit protection, to ensure the equipment’s safety against any possible electrical faults. Finally, standards such as IEC or UL, which signify safety, allow coordination and interchangeability with other certified parts, making the installation more sturdy and dependable.

Assessing Your Power Source Requirements

Since it is essential to anticipate your static or rotary frequency converter power needs, the most important thing to start with is checking what kind of input power, AC or DC, is available and the source’s voltage and current requirements. For example, applications where renewable energy systems are engaged, such as photovoltaic panels installed, require analysis where a wide range of voltage and variable power is presented. Moreover, suppose the power is unstable or of low quality. In that case, you must check whether some conditioning devices, such as voltage regulators or simple filters, conditioning filters, or stabilizers, would be required to protect those systems from destruction. One of the equally essential steps is calculating the relief loads so that the converter is not delivering hopeless peaks. Energy storage devices integrated into the converter also add to the reliability and preparedness of the system against intermittent power. By understanding these aspects, selecting a specific converter to meet the objectives and technical specifications will be possible.

Understanding Desired Output Frequency for Your Application

To assess the target operating frequency in light of my work, I evaluate the operational necessities and the frequency requirements of the driven load. This implies that the application runs on a standard frequency of either 50Hz or 60Hz. This means that it is more elaborate when compared to no changes at the standard frequency. I categorize and negotiate the boundaries of these technical specifications to ensure that the elements of the system function as full capacity equivalents, not competitively but synergetically. This prevents unnecessary wastage or loss, which hinders productivity.

Reference Sources

-

Analysis of Static Excitation System Models for Synchronous Machine

- Key Findings: This study compares two static excitation systems (ST1A and ST7B) for synchronous machines. It highlights the importance of excitation systems in maintaining generator stability and performance. The ST7B model demonstrated better damping enhancement compared to the ST1A model.

- Methodology: The research utilized MATLAB Simulink to simulate Single Machine Infinite Bus (SMIB) systems with the two excitation models. The study analyzed transient and steady-state responses to evaluate performance.

-

Modern Rotary Converters for Railway Applications

- Key Findings: This paper discusses the application of rotary and static frequency converters in railway systems. Despite advancements in static technology, it emphasizes that rotary converters remain preferred in Europe due to their reliability and efficiency in specific applications.

- Methodology: The study reviews recent designs and compares the performance of rotary and static converters in railway systems, focusing on their integration with public and railway grids.

-

Large Static Converters for Industry and Utility Applications

- Key Findings: The paper explores using large static converters in various applications, including HVDC systems, active filters, and steel mill drives. It highlights the role of advanced semiconductor devices in enhancing converter performance.

- Methodology: The research provides a comprehensive review of static converter technologies, their applications, and prospects, supported by case studies and technical analysis.

- Top Static Frequency Converter Suppliers In China

Frequently Asked Questions

Q: What is the main difference between static and rotary frequency converters?

A: The primary difference between static and rotary frequency converters is their operation and components. Static converters, including solid-state converters, use electronic components to convert frequencies, while rotary converters use mechanical rotation, similar to a generator, to achieve the conversion. This results in more compact and reliable static converters, whereas rotary converters are often favored for their ability to handle higher power loads and inrush currents.

Q: How does a static phase converter work?

A: A static phase converter temporarily uses capacitors to provide the necessary phase shift to start a three-phase motor on a single-phase power supply. Once the motor reaches a certain speed, the converter disconnects, and the motor runs on single-phase power, although at reduced efficiency. This method is often used for machinery that does not require full three-phase power for continuous operation.

Q: Can solid-state converters provide true three-phase power?

A: Yes, solid-state converters can provide true three-phase power. These converters use electronic circuitry to convert single-phase electricity into three-phase power with a stable output frequency, making them suitable for running three-phase equipment from a single-phase power supply.

Q: What are the advantages of using a rotary frequency converter over a static one?

A: Rotary frequency converters are often preferred for applications requiring higher power capacity and the ability to handle large inrush currents. They provide true three-phase power and can be more cost-effective for running heavy machinery and equipment that demands stable and reliable power.

Q: Why might someone choose a solid-state frequency converter?

A: A solid-state frequency converter is chosen for its compact size, reliability, and ability to convert AC power without mechanical parts. It is ideal for applications where space is limited and maintenance needs to be minimized. Solid-state frequency converters also provide a stable output frequency, making them suitable for sensitive equipment.

Q: What is the role of an inverter in a solid-state converter?

A: In a solid-state converter, an inverter converts direct current (DC) into alternating current (AC) at a required voltage and frequency. This is crucial in providing the correct power supply for three-phase equipment from a single-phase source.

Q: How does a rotary frequency converter handle variable frequency requirements?

A: A rotary frequency converter can handle variable frequency requirements by adjusting the speed of the motor-generator set. This allows for the output frequency to be modified according to the needs of the connected machinery, providing flexibility for various industrial applications.

Q: What is the significance of a soft start in static and rotary phase converters?

A: Soft start is a feature that helps minimize the initial surge of current, or inrush current, when starting motors. Soft start capabilities help reduce mechanical stress, extend equipment life, and prevent electrical issues during startup in both static and rotary phase converters.

Q: Are static converters suitable for all types of three-phase motors?

A: Static converters are generally suitable for simple three-phase motors where full performance is not critical. However, rotary or solid-state converters may be more appropriate for applications requiring full power and efficiency, such as those involving higher power or variable frequency needs.