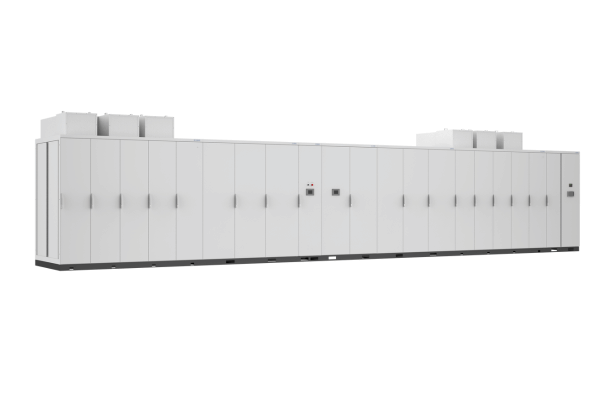

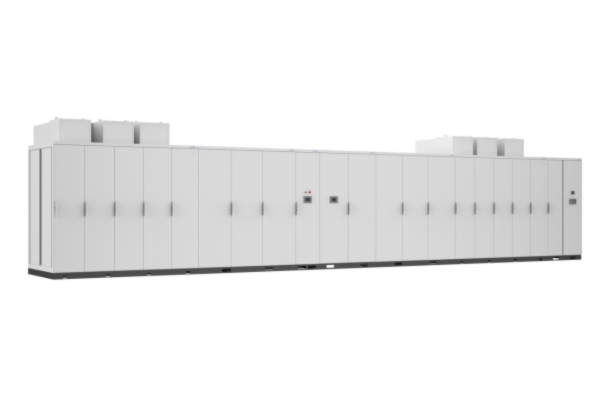

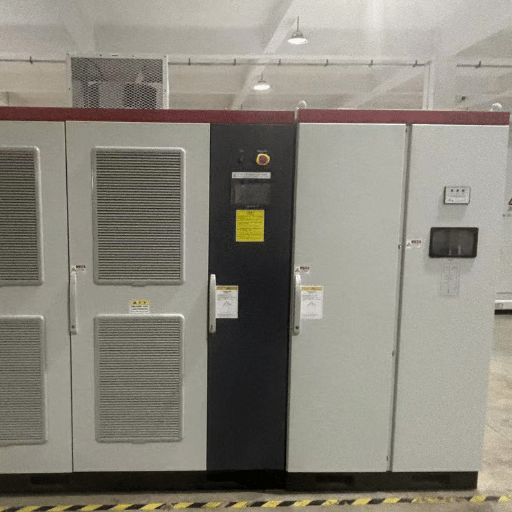

High Voltage Frequency Converters represent advanced solutions specifically engineered for managing substantial electrical power loads. They provide the essential capability to receive incoming power at high voltage levels and precisely convert it to varying frequencies and regulated voltages. This technology is indispensable for controlling large-scale industrial drives, integrating diverse power sources, and ensuring optimal operation of high-power equipment. By offering accurate and dynamic control, High Voltage Frequency Converters are fundamental to enhancing efficiency and flexibility in heavy industrial and grid-related applications.

Electricity is everywhere in today’s technologically advanced society. And, the challenge of optimal and efficient harnessing of electricity has been the main foundation upon which several industrial and technological...